The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

PAD --- Partially Air Dried; has a moisture content of 20 to 25% and so needs further drying before use. See air dried

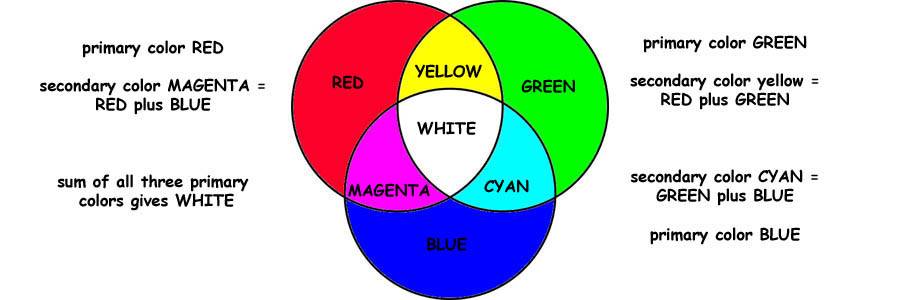

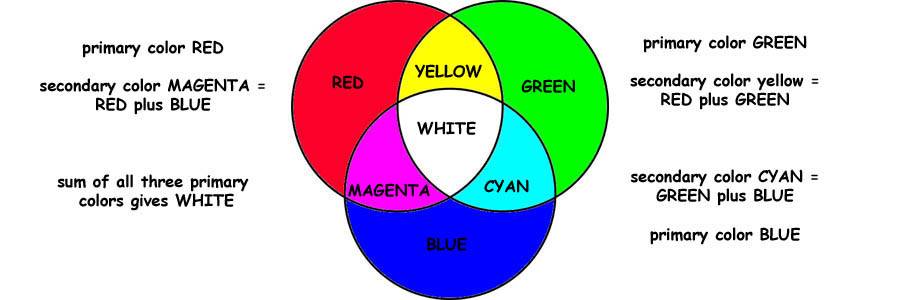

paint --- A liquid compound (especially a mixture of pigment suspended in a liquid) that is applied in a thin layer, or multiple layers, to a surface and subsequently dries into a hard, opaque, solid coating that protects and adds color to the object or surface to which it has been applied. There are numerous formulations for paint for both indoors and outside use. Compare/contrast to other finishing agents.

paint clearance --- A spacing in a hinge, this is the dimension between the inner edge of a leaf and the surface of the opposing knuckle. On many hinges, this space is just enough so that the leaf edge doesn't rub against the knuckle and squeek, but if a hinge is going to be painted then there needs to be enough paint clearance so that the rotation of the hinge does not cause the inside of edge of a leaf to scrape the paint off of the outside of the opposing knuckle. For an illustration, see hinge dimensions.

paint roller --- A cylinder covered with lamb's wood, felt, foamed plastics or other materials and used for applying paint in long swaths. Often used to paint large flat areas such as walls, but not often used to paint smaller wooden objects.

paint scraper --- A hand tool with study handle and a strong, sharp-edged, piece of steel that is used to scrape paint (and sometime other old finishes if they have bubbled up) off of wood and metal, usually as part of a refinishing project. These sometimes have a holding knob above the scraper so that extra force can be applied with one hand while the other hand pulls the scraper across a surface. Some have removable/replaceable blades and some are shaped so that more than one edge of the scraper can be used for scraping. Examples:

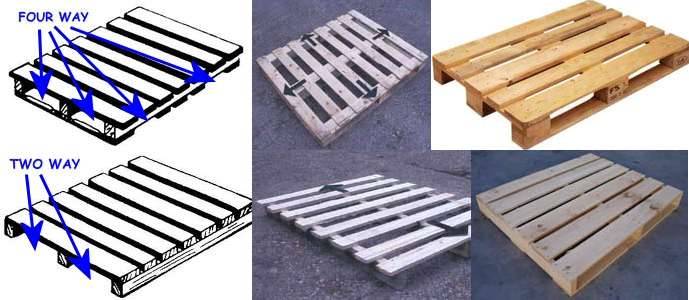

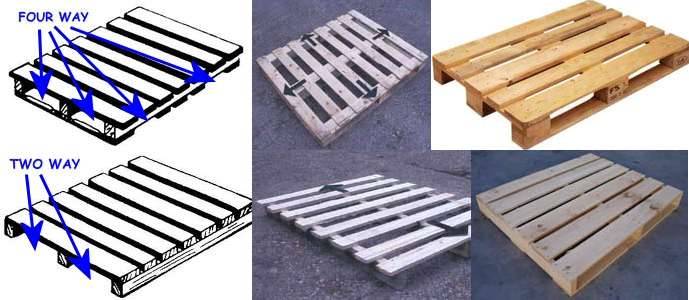

pallet --- A low wood platform on which material can be stacked to facilitate mechanical handling. Pallets have open spaces into which the tines of a forklift can poke so as to raise the pallet and whatever is stacked on it, for movement to another location such as onto or off of the bed of a truck. Pallets are typically made from low-grade, but strong, lumber that is not suitable for more refined use. This can include poor quality pieces of species such as oak that are otherwise used for high-end products. Pallets from foreign countries often have wood that we in the USA would not think of as pallet wood, because in the locale where the pallet was constructed, that wood IS pallet wood. I've had many correspondents regale me with stories of the marvelous "found" wood they got off of discarded pallets. Pallets are classified as "2-way" or "single face" and "4-way" or "double face" depending on how many directions the forklift can insert its tines under or into the pallet. There are also different support designs called "stringer", "block", and others but I just can't get excited enough about pallets to break out all of the configurations and the information is readily available on the Internet. Examples:

palm sander --- A power sander that is quite small and so named because it is controlled by the palm of one hand. There are three types of palm sander; the square bottom version (aka quarter sheet sander), the round bottom, and the triangular bottom (aka detail sander). Although all detail sanders are palm sanders, not all palm sanders are detail sanders. All palm sanders are orbital sanders. Compare/contrast to other forms of power sander. Examples:

panel --- (1) A sheet of plywood, or other composite material, usually 4x8 feet which is the standard size for such panel items.

panel --- (2) A sheet of wood that forms a distinct (usually flat and rectangular) section or component of something. For example, rail and stile construction uses panels of wood that float inside the rails and stiles, and this technique is used on cabinet doors, house doors, and elsewhere. Such a panel could be one piece cut off of a wide plank, but more often they are built up from parallel planks jointed together.

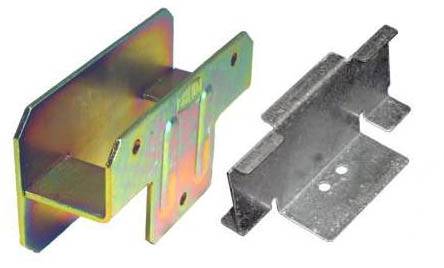

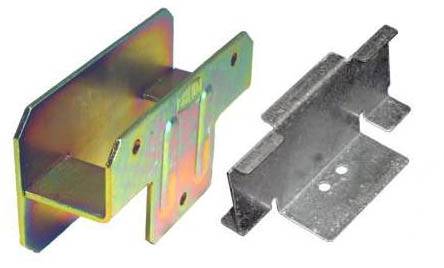

panel clip -- Any of various shaped metal devices for supporting the edges of adjacent panels so that their edges do not move relative to each other. Very useful in situations where two panel edges come together but there is no support behind or beneath them to keep them flush. Examples:

paneling --- Large wooden sheets (usually 4' x 8') joined in a continuous surface, especially decorative panels for interior wall finish. Textured plywood in many varieties is often used as interior paneling either in full wall sections or accent walls. They usually consists of vertical grooving of some sort that makes it appear as though the panel is a series of separate planks.

panelized construction --- Large structural components such as walls, floors, roof sections, etc, that are built in a factory and then assembled into a completed structure at the building site. This speeds up overall fabrication of a building, cuts on-site labor costs, and offers high quality subassemblies through controlled factory production and inspection procedures.

panel joint --- A joint where the edges of two planks are butted up against each other. The joint can be just glued, or it could be reinforced with biscuits, dowels, or a spline. Examples:

panel spacing --- The gap left between installed panels in a structure. Panels in floor, wall or roof deck construction should be spaced to allow for movement in service. Because panels are not usually made from solid wood, they typically have small movement in service, but small is not zero, so some clearance should be left.

paper --- A type of backing on sandpaper

paperboard --- Grades of paper whose thickness is more than 0.012 inches and which are heavier and more rigid than ordinary paper.

paper joint --- Despite containing the word "joint", this is not a joinery term but rather a description of the use of paper (generally Kraft paper as a separator when gluing a glue block to a workpiece for face turning so that the glue block gets the screws from the faceplate rather than having them go into the workpiece. Paper joints are also sometimes used in spindle turning when it is desired to turn a spindle that is actually two or four sections glued up to be turned together before being applied separately. The paper joint makes it easy to separate the parts of the spindle once it has been turned.

PAR --- Prepared All Round; synonymous with S4S. I have only one source for this term and am dubious about it; I've never otherwise seen it or heard it.

parabola --- A mathematical curve that has the property that if you build one out of a reflective material and put a point-source light at the focus, the light will be projected outward all in parallel rays. That's how car headlights work. What does this have to do with woodworking? Well, as it turns out, parabolic arches are stronger than semi-circular arches, and part of this glossary is about construction techniques. See also, catenary.

parabolic --- Having to do with a parabola. Parabolic arches are stronger than semicircular arches.

parabolic arch --- An upward curving arc with a parabolic curve. Although the Romans, great builders of arches, used semi-circular arches that have lasted for thousands of years, it is now known that parabolic arches and catenary arches are actually somewhat stronger.

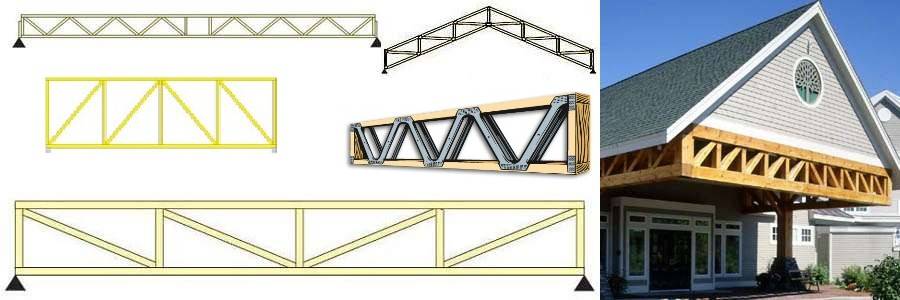

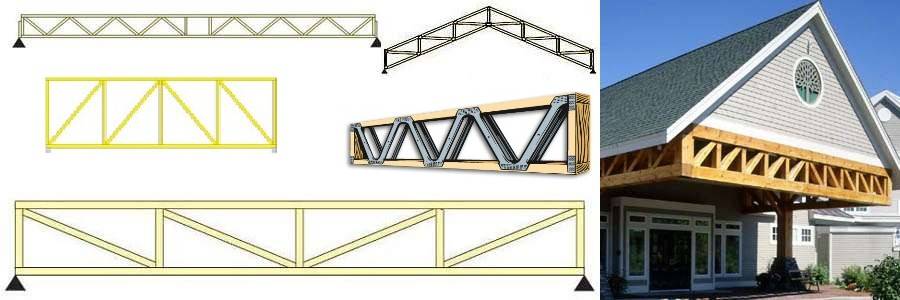

parallel chord truss --- A truss that has parallel upper and lower chords and that is used for upper story floor supports and flat roof supports. There is a version called the vaulted parallel chord truss that is used at a slant (there's one of them in the upper middle of the examples below). Examples:

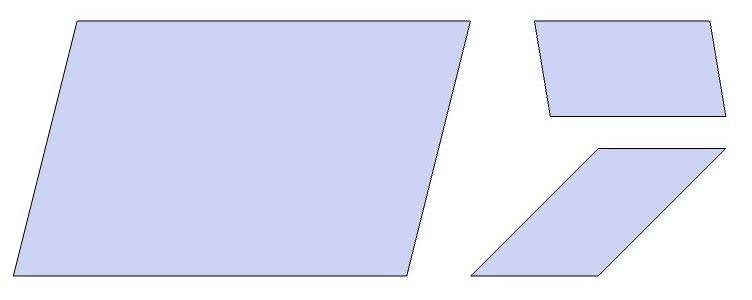

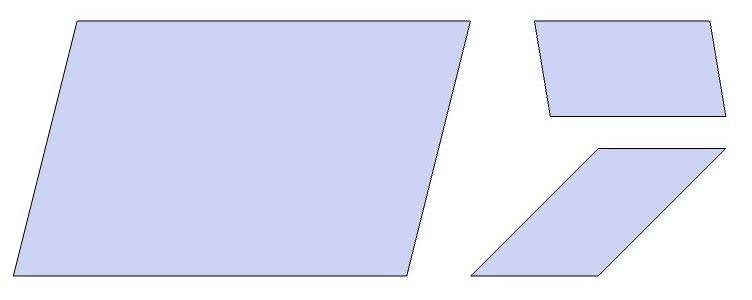

parallelogram --- A shape like a rectangle that has had its top line shoved over to one side or the other. The term technically includes rectangles (a rectangle is a parallelogram with a corner angle of 90 degrees) and squares (a square is a rectangle with all sides having the same length). Compare/contrast to trapazoid. Examples:

parallelogram jointer --- A jointer with a particular kind of precision adjustment mechanism for the table that is advertised to provide very accurate table adjustment over a long life, so that the infeed and outfeed surfaces remain coplanar, which is crucial to accurate surfacing.

parallel strand lumber --- A structural wood product made from softwood veneer that has been sized into long and narrow strips that are then glued into parallel laminations with the wood grain all running in the same direction. It's very similar to laminated veneer lumber.

pare --- As regards woodworking, this means to slice a small amount off of the surface of something, such as is done with a paring chisel.

parenchyma --- Also called ground tissue or soft tissue, these are tree cells that perform non-structural life process functions such as food storage and the production of resins, gums, extractives, and tyloses. They remain alive longer than tracheids, fiber, and vessel elements, sometimes for many years. Two kinds of parenchyma cells are recognized: those in vertical strands, known more specifically as axial parenchyma, and those in horizontal series in the rays (which are formed entirely of parenchyma cells), and known as ray parenchyma. In conifers, parenchyma cells form resin ducts or canals in the rays, usually at the end of each growth ring. Parenchyma is often lighter in color than the rest of the wood and the pattern of its arrangement is used as an identifying characteristic for tree species.

paring --- [verb] To slice a small amount off of the surface of something, such as is done with a paring chisel.

paring --- [noun] A thin fragment or slice that has been shaved from something.

paring chisel --- Light, long, thin, almost flexible joinery chisels (well, those from some vendors are pretty clearly NOT flexible). They are used primarily for carefully shaving off thin amounts of wood when fitting joints, and are never hit with a mallet but rather are pushed with both hands in a controlled stroke where one hand on the handle pushes the chisel forward while the other hand, up front on the blade, guides the cutting action. A classic use is to dress the sides of a mortise after roughly chopping it square with a mortise chisel. There are both straight and cranked versions. Somewhat oddly, I find, many definitions list these as being rectangular in cross section, but all of those sold today appear to be trapazoidal in cross section. Examples of both uncranked and cranked paring chisels:

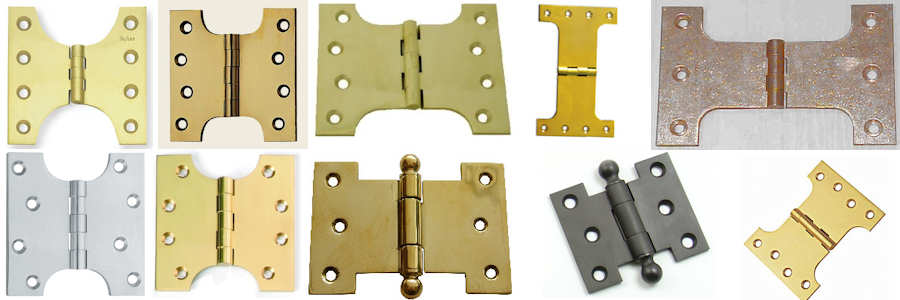

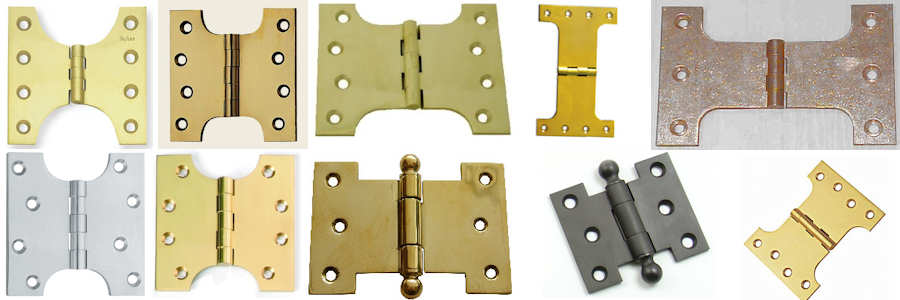

parliment hinge --- A type of hinge that seems to be mostly used in Great Britain, this is a butt hinge that has had scoops removed at the top and bottom which shortens the (hinge) barrel. This reduces its strength, but some people feel that it provides a more aesthetically pleasing appearance, even though since it is normally used as a projection hinge, the scalloped leaves are mostly hidden when it is closed. These are also called "butterfly hinges" in Great Britain, but they would never be confused with what Americans call a butterfly hinge. Although normally mounted as a projection hinge, they are occasionally face-mounted and are used just for the decorative effect, much like the American butterfly hinge but less gaudy and a bit more elegant. Examples:

parquet --- Wood flooring laid using parquetry.

parquetry --- (1) A process of laying flooring tiles (of wood or other material) into geometric patterns. The patterns can be very simple or quite complex and the floor may or may not contain one or more medallions.

parquetry --- (2) Like marquetry, this is a technique for creating images from wood veneer. The difference is that marquetry is used to create free form images that look like paintings, whereas parquetry is used to create geometry designs, frequently of repeating patterns. Compare/contrast to inlay.

Examples of parquetry --- these are all flooring except for the two boxes which are veneer:

parson's table --- A table that has square legs that have the same width in both directions as the table is thick, thus presenting a very sparse design. waterfall tables are sometimes mitakenly identified as parson's tables. examples:

partially air dried --- [PAD] lumber that has been stickered and allowed to air dry for some time, but still has a moisture level above the 19% required for a "dry" designation. See air dried.

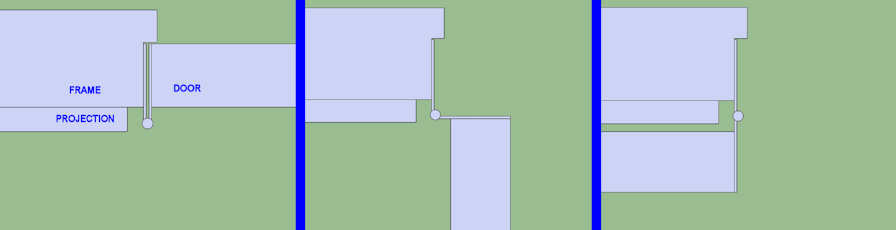

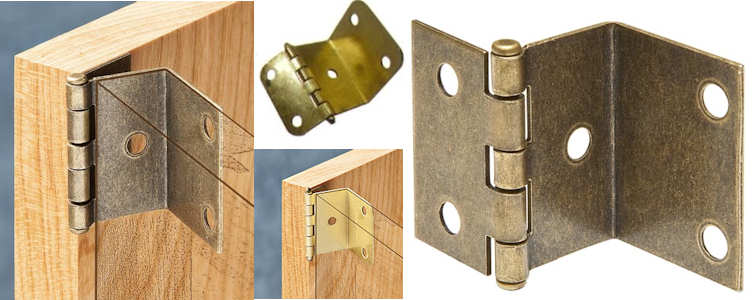

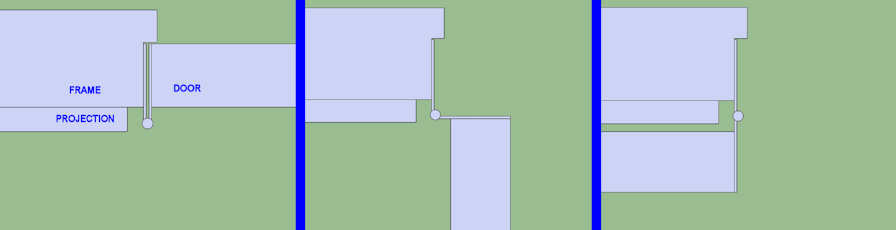

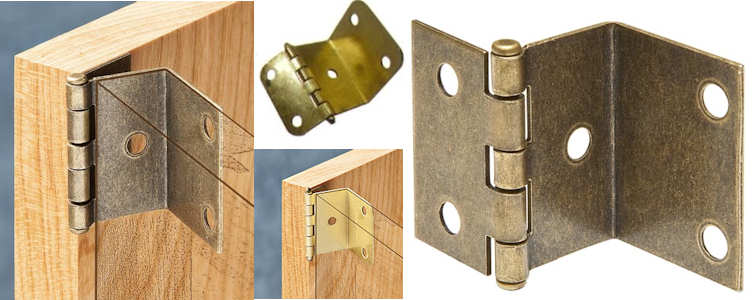

partially concealed hinge --- Any hinge that has part, but not all, of the mechanism hidden from view when the hinged object is closed. This is not so much a TYPE of hinge as it is a MOUNTING TECHNIQUE for a hinge. For example, a butt hinge when mounted to the edge of a door and to the frame directly opposite the edge (see edge mounted hinge) is a partially concealed hinge, but if that same hinge is face mounted then it is NOT partially concealed. Compare/contrast to fully concealed hinge.

partial overlay face frame door --- see face frame door

partial wrap around hinge --- A type of hinge that wraps around both the edge and the back of either a door or a frame and butts to the edge of the other. This is a truncated version of the full wrap around hinge; it provides the same 180 degree range of motion as the full wrap around but slightly less mounting strength. The partial wrap around hinge is typically used in a frameless cabinet whereas the full wrapaound is used in a face frame cabinet. Examples:

particle board --- Also called chipboard in the UK and some other countries, this is an engineered wood product manufactured from wood chips, sawmill shavings, or even saw dust, plus a synthetic resin or other suitable binder, all of which is pressed together under high pressure and heat to form panels. Particleboard is a type of fiberboard, a composite material, but it is made up of larger pieces of wood than medium density fiberboard and hardboard. Particle board is very dense, heavy, and flat, but not generally suitable for exterior use and not suitable for structural elements of a building. Particle board is sometimes used as the core for a kind of plywood called, appropriately enough, particle-board core plywood. Particle board is also called "flakeboard". When used in cabinetry, particleboard is often joined using confirmat screws.

particleboard-core plywood --- plywood that is made by gluing thin layers of veneer to a piece of particleboard. Contrast to veneer core plywood and lumber core plywood.

particle board screw --- As the name says, this type of screw is designed for use with particle board. They are very similar to drywall screws. Most definitions say that they are THINNER than drywall screws, but that seems odd to me since particleboard is heavier than drywall. Looking at screws that are actually sold as one or the other, it is a mixed bag as to which is thicker. Like drywall screws, these have coarse threads and the outer diameter of the threads is larger than the shank. They have countersunk heads and are usually made of steel, but unlike drywall screws the countersinks tend to be uncurved instead of the curved ("bugle") type found on drywall screws and also unlike drywall screws, these tend to have an unthreaded section below the head. The drive slot is most often an Allen head. These screws often use hi lo threads. Compare/contrast to drywall screw Examples:

parting --- [verb] In lathe turning, the use of a parting tool to separate a spindle turning into two parts, typically to either (1) cut off the waste portion at the end of a turning or (2) so that the parts can serve as the upper and lower halves of lathe boxes. Parting can also describe the separation of a face turning from the faceplate.

parting tool --- A lathe tool that is used to separate a spindle turning into two parts, typically to either (1) cut the work piece off from the waste portion at the end of a turning or (2) so that the parts can serve as the upper and lower halves of lathe boxes. There are four flavors of the tool, all with the same fundamental purpose, as follows:

partition wall --- A wall that bears no load other than its own weight and is purely for the purpose of partitioning off an area of a building. Compare/contrast to bearing wall.

paste --- [noun] Specifically, an adhesive made from water and flour or starch to be used on paper and cardboard (think kindergarden) but more generically, any adhesive that has a soft and pliable consistency, and by extension, the characteristic of being soft and pliable, as in "paste wax".

paste --- [verb] to glue onto; to cause to adhere to; "He pasted the template onto the substrate".

pat --- An application technique for putting a finishing agent onto wood. It consists of tapping (patting) a cloth or sponge or other item soaked with the finishing agent onto the surface to be finished. Patting is used almost exclusively with paint and is done to achieve a rough and/or mottled surface texture, which is the exact opposite of other application techniques, all of which have the goal of achieving a smooth finish.

patch --- A patch is a sound wood insert used to replace a defect in a veneer covering on a panel. Boat patches are oval shaped with sides tapering to small rounded ends (like the longitudinal cross section of a football). Router patches have parallel sides and rounded ends (like the shape of a high school track oval).

patina --- The color and texture that a material acquires on the surface as a result of a natural aging process. Bronze, for example, acquires a green patina due to oxidization. Many types of wood acquire a patina that is one or the other or both of (1) surface oxidization, and (2) the results of exposure to sunlight (ultraviolet light). The depth of a patina in wood will vary greatly depending on the wood, but most patinas are only "skin deep" and can be removed by sanding, scraping, etc. Others may go down to 1/8" or more. In the examples below, the upper image is the freshly sanded wood and the lower pic is of the same plank prior to sanding. The particular piece of goncalo alves shown has an unusually heavy patina for the species (for ANY species for that matter).

patterned lumber --- lumber that is shaped to a pattern. Most often this is a pattern that makes the lumber more attractive and/or more usable as siding. The pattern might be, for example, longitudinal grooves that give the planks a somewhat more fancy look than they are when plain, and the grooves would match a particular form of shiplap joint construction.

pattern stick --- A thin, flat piece of wood on which is cut (with a scroll saw or fret saw) the outline of what a spindle turning is supposed to look like. That is, the silhouette of the finished turning should have the exact same contour as the edge of the pattern stick. This is particularly useful when making multiple identical copies of a turning. The pattern stick can be held right up against the turning to judge how high or deep to make beads and coves and other turning features. There is a similar, but less extensive tool called a story stick.

paumelle hinge --- A hinge that, much like the olive knuckle hinge, has only two (hinge) knuckles but with this hinge, the knuckles are very elongated and have a modernistic, streamlined look. These are more aesthetically pleasing (more "decorative") than, for example, a plain butt hinge but they are somewhat weaker. Examples:

need to add paumelle hinge pics

need to add paumelle hinge pics

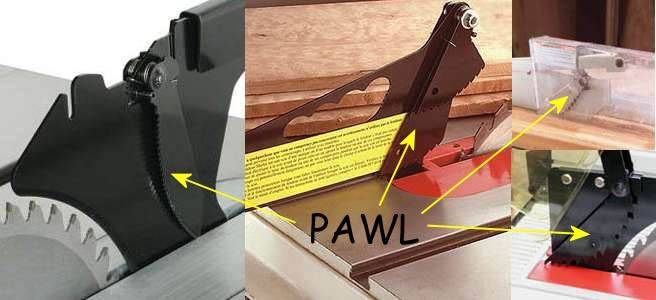

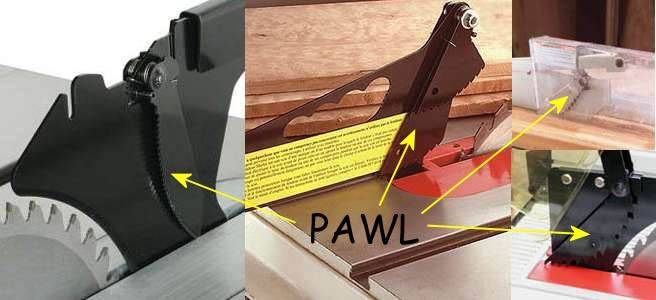

pawl --- A pivoted pointed piece of metal designed to grip a workpiece as soon as it is thrown back by a moving blade or cutter. This is an anti-kickback device. All of the examples below are on table saws and they are all of the form of a freely swinging pawl that offers absolutely no resistance to a plank that is moving in the right direction but as soon as a plank kicks back against them, they jamb against it and prevent movement in the wrong direction. The pawls are usually attached to the splitter.

pea gravel --- A self-compacting fill material consisting of pea-sized rocks.

peanut shell --- There is a form of blister or pomelle figure found fairly often in tamo (Japanese Ash) and less frequently in a few other woods such as bubinga, where the grain pattern forms into the classic shape of a peanut shell (the standard, common, kind with two peanuts in one shell). It has a very "busy" look but can be quite attractive. As far as I know, it only occurs in veneer that is produced by rotary cutting logs that have a particular form of irregular grain. Below is a composite pic of two sheets of tamo ash veneer and two sheets of bubinga, all with the figure, although as you can see, it is much stronger in the tamo than in the bubinga. To see a few more pics, click here: peanut shell pics

peavey --- A lumberman's lever consisting of a wooden shaft with a pointed metal tip and a hinged hook near the end, used to handle cants or logs. Exactly like a cant hook except that the cant hook does not have the pointed tip. Examples:

peck --- see pecky

pecky --- Pockets or areas of disintegrated wood caused by advanced stages of localized decay in the living tree, caused by a fungus. There is no further development of peck once the lumber is seasoned.Cypress and incense cedar are two woods in which pecky condition is common and it also occurs in pecan/hickory and occasionally in other woods. In the composite image below are pecky forms of pecan, then beech, then an unknown wood.

pedestal bowl --- A bowl that sits on top of a shorter turning designated a "pedestal" or "foot". The pedestal COULD be turned from the same integral piece of wood, but often is turned from a different wood glued to the upper "bowl" portion. Compare/contrast to other lathe turnings. Examples:

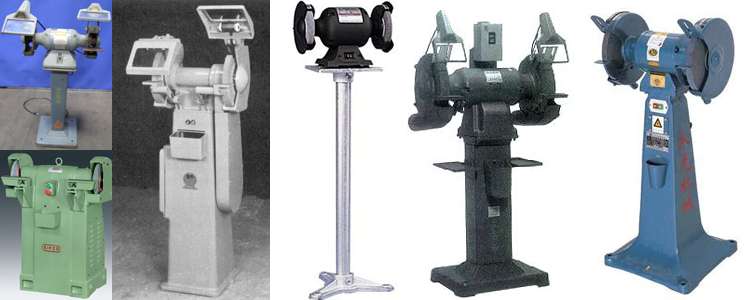

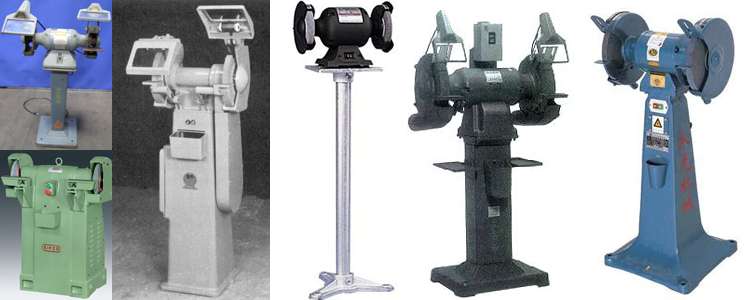

pedestal grinder --- A bench grinder that is mounted on its own stand, or a slightly more complex setup that amounts to the same thing. Examples:

peel --- To convert a log to veneer using the rotary cut technique.

peeled veneer --- see rotary cut veneer

peeled veneer flooring --- Some flooring material is made using the same construction techniques as plywood except that the constructs are in the form of planks rather than panels. When the top layer of such a construct is made using veneer that is peeled off of a log using rotary cutting, it is called peeled veneer flooring, and if it is created using sawn thin wood, it is called sawn veneer flooring. Some reports note that both such products can be installed in a basement over concrete, and that statement seems to imply that solid wood flooring cannot, but I don't see why there should be such a distinction.

peeler log --- A veneer log specifically selected to be rotary cut because of its characteristics (which can vary, depending on whether it is destined for plywood or decorative veneer.

peeling --- (1) Converting a log to veneer using the rotary cut technique.

peeling --- (2) The condition in which a layer, or layers, of a finishing agent lifts up from the surface due to poor adhesion.

peen --- The part of a hammerhead opposite from the striking side; comes in various shapes, most commonly a claw (see claw hammer, or a ball (see ball peen hammer.

peg --- a square or round length of tapered wood. May be used to joint pieces of wood by driving it into holes in the mating pieces. Small pegs are used as markers in various games.

PEG --- polyethylene glycol

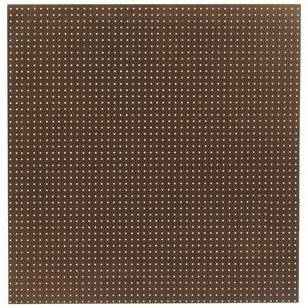

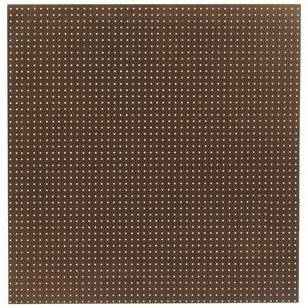

pegboard --- A perforated hardboard, plastic, or metal panel, pre-drilled with evenly spaced holes. The holes are used to accept pegs or hooks to support various items, such as tools in a workshop. The metal and plastic versions are fairly rare in home use, but the hardboard version is used in garages all over America, both the kind where cars are repaired and the kind where we hobbyists have our woodshops instead of our cars, which we leave out in the cold). They are a marvelously convenient way to hang small tools. I don't think I have ever seen a glossy-magazine picture of a spotlessly clean woodworking shop that does not include a pegboard panel (hardboard, not plastic or metal) full of tools. The variety of tool holder devices designed to fit into pegboards is practically infinite. There are two thicknesses available, 1/8" thick for regular use and a 1/4" thick version for hanging pretty hefty tools, and the hanging inserts are not interchangeable between the two. Examples:

pegged --- see peggedjoint and tusked mortise and tenon

pegged joint --- Refers to a joint that is reinforced with dowels. Also, a tusked mortise and tenon is sometimes called a pegged mortise and tenon.

pegged mortise and tenon --- synonymous with tusked mortise and tenon

pellets --- An energy source made from 100% compressed wood (usually sawdust) for use in fireplaces and fire stoves.

penblank --- A piece of wood that is destined to be turned into a pen on a lathe. Usually about 3/4" x 3/4" x 6" and made of exotic wood.

pencil trimmed --- When lumber is counted in board feet for sales, only usable lumber is supposed to be counted. It can be physically trimmed first to get rid of the splits on the end and so forth, or it can be pencil trimmed. That's where the seller/grader just makes a mark where he thinks the board end would need trimmed down to. If it is pencil trimmed, then only the wood between the pencil marks is counted in the BF total.

penetrating finish --- A finishing agent that is absorbed into a surface rather than forming a film. Tung oil, linseed oil, and Danish oil are examples of penetrating finishes.

penetrating oil --- (1) see penetrating finish

penetrating oil --- (2) A type of low-viscosity oil that penetrates into metal joints (usually bolt threads) that have become locked up, usually by rust, so as to loosen them up.

penny --- see nail sizes

penny size --- see nail sizes

percent solids --- Percentage mass of non-liquid components in finishing agents.

perforated hardboard --- see pegboard

pergola --- A wooden structure consisting of posts topped by crossbeams, the whole of which is designed to be covered by climbing plants to provide a shaded area in a garden. A type of arbor. Examples:

permanent set --- A change in the properties of wood which can occur during drying when stresses exceed the elastic limit of the wood. Permanent set prevents normal shrinkage of the timber and can lead to more obvious defects such as case hardening and honeycombing.

permanent wood foundation --- A residential and light frame building foundation system utilizing pressure-preservative-treated wood framing, including plywood panels, in place of the more normal poured concrete footings and masonry or poured concrete foundation walls.

permeability --- the degree to which a wood is permeable.

permeable --- The degree to which a substance allows fluids to come into it. The term is most relevant regarding wood when discussing the degree to which the heartwood or sapwood of a given species does or does not allow the entrance liquids such as preservative treatments and flame retardants. There are two major effects of a wood being highly permeable. First, it that makes it a terrible wood for tight cooperage and second that makes it easy to treat with preservative treatments. Contrast to impermeable. NOTE: In standard English, the term porous has as one of its definitions something very like permeable, but as regards wood it should not be used that way and permeable is the correct way to refer to wood that allows the passage of fluids; nonetheless, "porous" is widely used, incorrectly, to mean permeable in woods.

perpendicular --- Refers to two surfaces that are at a 90 degree angle to each other

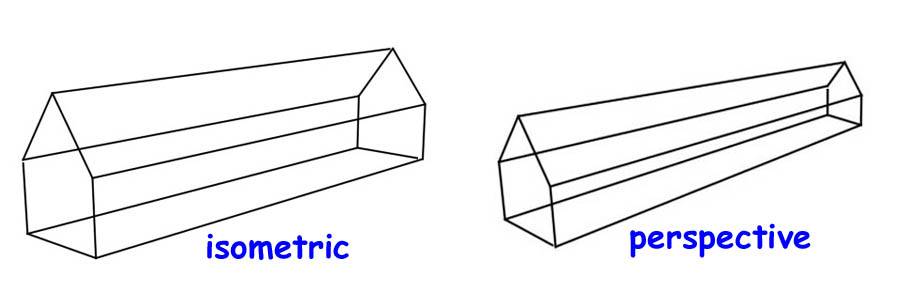

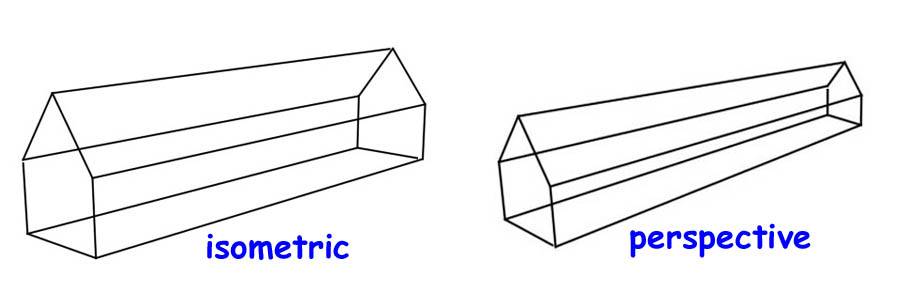

perspective drawing --- A drawing in which lines that are parallel in reality are NOT shown as parallel in the drawing, but rather are shown converging because that is the way we perceived them (even though we know they are parallel). In woodworking, one normally uses isometric drawings, which are more amenable to conveying technical details. Compare/contrast to isometric drawing. Example:

PET --- Precision End Trimmed

petrograd --- A Scandinavian standard measurement unit for softwood lumber volume. I have seen a couple of definitions, running around 150 to 160 cubic feet (just under 2000 board feet

petroleum --- technically, this is a generic name for numerous naturally occurring compounds made from various hydrocarbons, including crude oil, natural gas liquids, natural gas and their products, but in common use if often refers just to "crude oil" which is the dark naturally occurring oil made primarily from hydrocarbons that oil wells produce bring out of the ground. It is the basis for a truly HUGE array of man-made products, not least of which is all forms of gasoline.

pewter --- A metallic alloy of tin and small amounts of other metals such as lead, copper, bismuth or zinc. Widely used in America from the early 1700's to the early 1800's.

phenolic --- A particular type of thermosetting resin, the chemical composition of which is beyond the scope of this glossary. As a solid, it is used in making non-conduction washers (see phenolic washer and as a chemical compound, it is used in some finishing agents.

phenolic Veneer --- A flexible veneer face with a phenolic type backing material. Sometimes referred to as laminate veneer.

phenolic washer --- A type of washer in which a particular type of nonconducting material (phenolic) is used to prevent electrical conduction between a screw or bolt and the material into which is is inserted. This is to prevent galvanic corrosion, although that is also prevented by several other types of non-conducting shoulder washers. Examples:

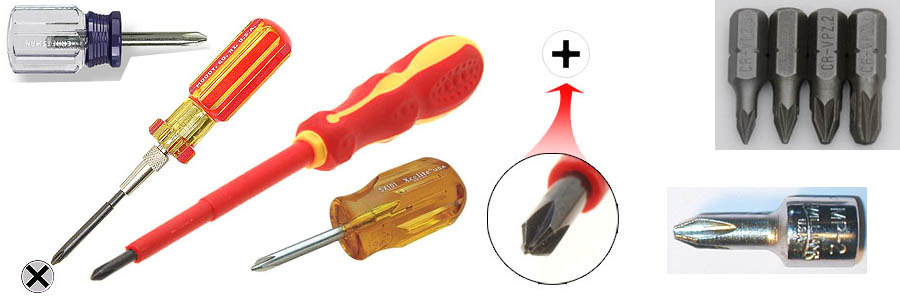

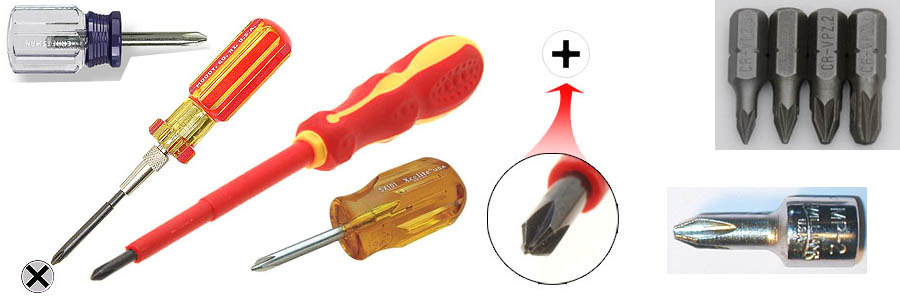

phillips head --- A type of screw or bolt head requiring a driver in the shape of plus sign instead of the minus sign shape of the normal flat head screwdriver. The phillips head drive provides a little more protection against stripping the slots than does a flat head screw and driver, but not really all that much; they still strip pretty readily. Compare/contrast to flat head. Examples:

phillips head screw driver --- A screw driver with a head in the shape of a plus sign, rather than the minus sign shape of the normal flat head screw driver. Used to drive phillips head screws, these provide a little more protection against stripping the drive slots than do the flat head screw and driver, but not by much. Examples:

phloem --- The inner bark of a tree. In the life process of a tree, water is carried from the soil up into the tree in the sapwood and carbohydrates (sugars), formed in the leaves by photosynthesis, form a sugary water which is the sap of the tree which flows down through the cells in the phloem to the branches and trunk and feed the cambium. Although technically the term phloem only refers to the live, inner section of the bark, it is used colloquially as synonymous with bark, meaning all of the bark and it is also called "bast". The phloem of some trees has been used by various peoples throughout history as both a food and a fiber source for woven goods. In such uses, it seems to be referred to as "bast" much more than as "phloem" but I have not seen anything suggesting that these terms are not totally synonymous, it's just that phloem is used more as a description of something relative to the tree and bast is used to describe the same thing as it relates to the rest of the world.

photosynthesis --- The metabolic process in trees whereby leaves convert water from the soil (brought up to the leaves by the sapwood) and carbon dioxide from the air into organic compounds, especially sugars, using the energy from sunlight. This is the primary growth driver for all green plants, including trees and it is the carbon dioxide absorption that makes trees terrific fighters against global warming. Once the sugars are formed, the sugary water, called sap is carried back down the tree in the phloem where they feed the cambium cells which is where the tree growth takes place. Not only do trees absorb carbon dioxide they produce oxygen as part of the process, so trees are a just a marvelous benefit to all living things on the planet and that's why a lot of us get so upset about how the rain forests, and other forests, are being decimated by industrialization.

phylum --- see taxonomy for a discussion

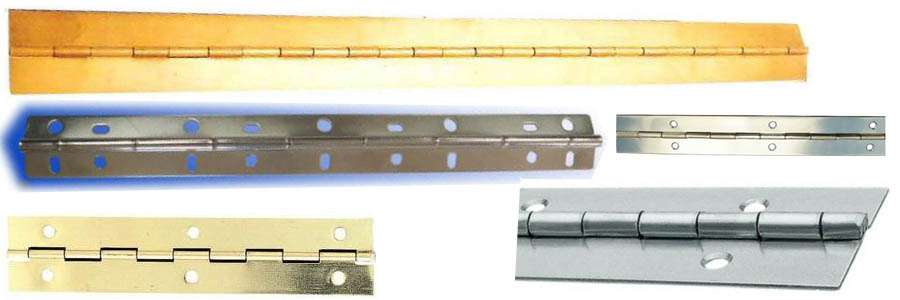

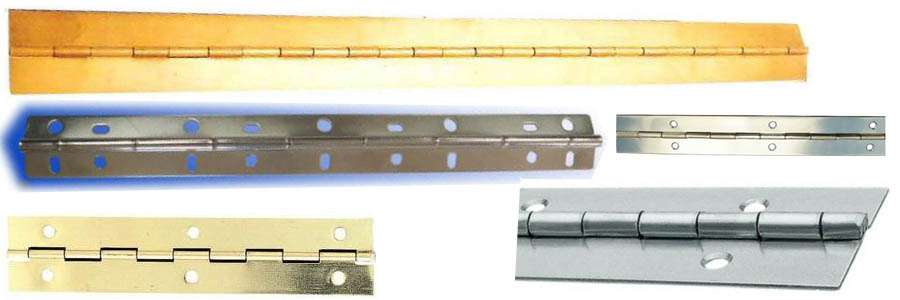

piano hinge --- [aka "continuous hinge"] A long (sometimes VERY long) butt hinge. The name derives, rather obviously, from the fact that this kind of hinge is used on pianos, among other things. Examples:

piercing saw --- A saw very much like a coping saw but designed to be used on jewelry material such as sliver and gold and used by jewelers rather than woodworkers. Examples:

pigment --- A substance that gives color to something. In wood, the pigments are various chemicals that give various woods their characteristic colors. The term also refers to the chemicals that give finishing agents their color.

In most woods, hardwoods in particular, the pigments in the heartwood are different from those in the sapwood. In some species, the pigments are water soluble, even to the point where some trees are what is called dye wood, and in some they are not. Dyewoods are used to transfer the color from wood pigments into fabric. Water stain in wood is the action of water on the pigments in the wood (water stain can also refer to stains left on wood by pigments transferred in from contaminated water).

pigment volume concentration --- [PVC] The percent (by volume) of pigment in a paint.

pile --- A long, heavy timber, round or squared-off, that is driven deep into the ground to provide a secure foundation for structures built on soft or wet soil, or at the edge of a body of water. Examples of such use include piers, bridge abutments, and beach-shore houses.

piling --- see pile

pilot bearing --- synonymous with roller bearing

piloted bit --- A router bit that has a roller bearing that pilots the bit around a template.

pilot hole --- A hole drilled in a workpiece to receive the threaded portion of a screw. The pilot hole is just slightly smaller than the screw's thread diameter. Pilot holes are drilled for one (or both) of two reasons; first, to make sure the screw travels on the intended path in the wood rather than being deflected by the grain of the wood and second, to prevent the wood from splitting when the screw is inserted --- many wood species are hard enough that the insertion of a large nail or screw will not locally crush the wood fibers away from the inserted metal as happens in softer wood, but rather will cause the wood split along the grain.

pin --- (1) A dowel segment (also called a dowel pin) or other long thin inserted element used to add strength to a joint.

pin --- (2) see hinge pin

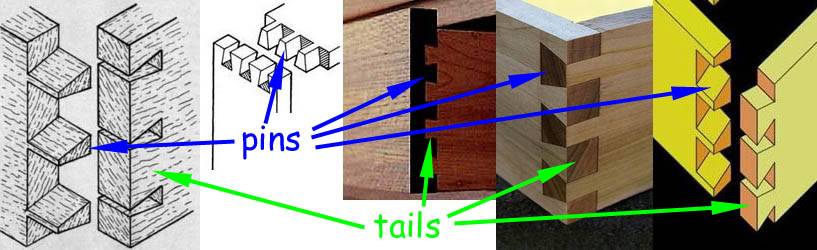

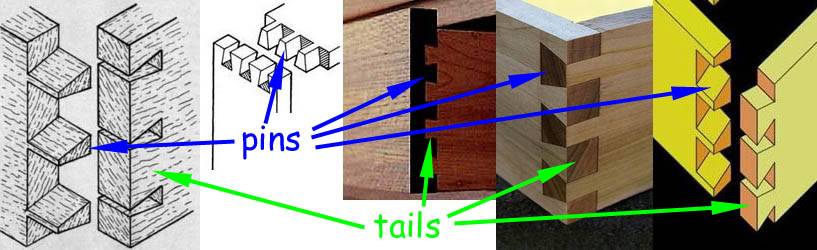

pin --- (3) Half of the locking mechanism in a dovetail joint. A dovetail joint consists of flanged projections called tails on one plank and a set of corresponding recessed areas on the other plank, with the protruding sections between the recesses being called pins. Although a dovetail joint has maximum strength when the pins and tails are the same size, aesthetic considerations often lead to the craftsman making the tails bigger than the pins. Examples:

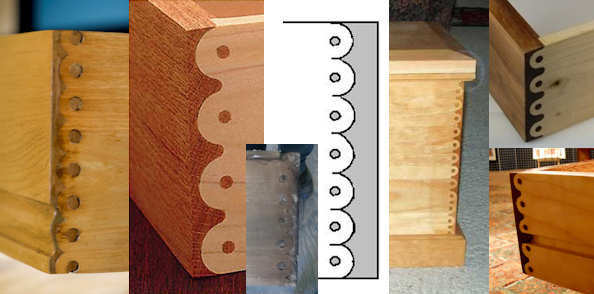

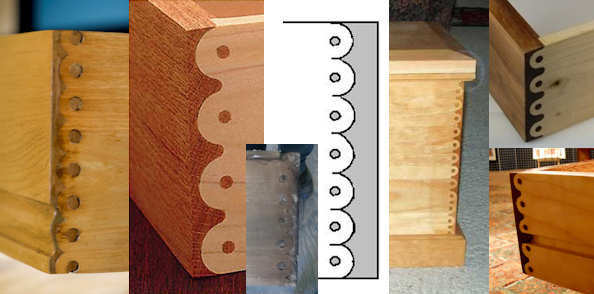

pin and crescent joint --- A particular kind of drawer-front joint that joints the sides to the front with a scalloped cut on the sides, with holes in the semi-circles this creates, and pins in the drawer front that go through the holes. It's a very strong joint, but looks to me like a major pain to create unless you use the specialty router template that is available. These are also called "scallop and dowel" joint, "pin and scallop" joint, "half moon" joint, and "knapp" joint. Examples:

pinch dog --- A type of clamp that is a rectangular "U" shaped piece of metal with sharpened wedge-shaped ends that are driven into the ends of planks that are being glued together so as to pull them together without the use of other clamps. Examples:

pin hinge --- A hinge that consists of nothing but the (hinge) pin. There are two basic uses for this form of hinge. The first is where the (hinge) knuckles are just the object being hinged itself and the pin is put directly into holes drilled in the top and the base of the object and the top then rotates off of the base with the roation centered on the pin. These are used in specialty items such as small ornamental jewelry boxes. The second type is where a flat, inset, box lid has a pin coming out of the rear of each edge and going into the carcass. Examples

need to add pics

need to add pics

pin hole --- A small hole in the surface of a finishing agent: see pinholing.

pinhole --- (2) Small hole in wood produced by small insects known collectively as pin hole borers. Technically, many definitions restrict "PIN holes" specifically to holes no more than 1/16" in diameter. Here's a pic of an 8-inch wide section of an andiroba plank, in which the sapwood (which is what is usually attacked by pin hole borers) is just starting at the top of the pic and the pin holes are coming down into the edge of the heartwood:

pin hole borers --- Small critters that bore very small holes in wood ... I have not found any more specific definition of the borers. See pin hole for an example of their work.

pinholing --- The appearance of numerous small holes in a film, usually caused by bubbles that were in the film as it dried and burst before full drying, leaving craters in the surface. Some definitions say that pinholing specifically refers only to holes (not craters) that go all the way through the film.

pinion --- The circular gear portion of a rack and pinion mechanism.

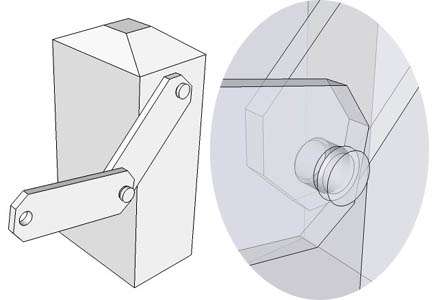

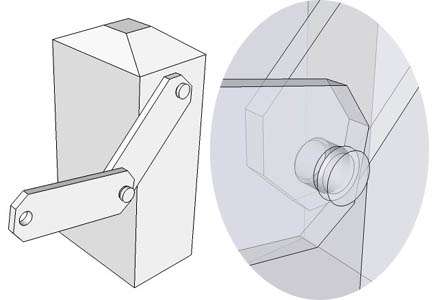

pin joint --- A connection where one piece of wood is free to rotate like a hinge because of a pin going through it. Not to be confused with pinned joint which is a supporting/strengthening mechanism for static joint. The pin joint is used in some wooden toys among other things; the range of motion depends on the rest of the construct in which it exists, but is usually at least 90 degrees and can be a full 360 degrees. A good example is the way the arms are attached to many simple moving wooden human-like figures, a rough example of which is shown below:

pin knot --- a knot that is, depending on what source you reference, either less than 1/4" or less than 1/2", in diameter. Pin knots are generally implicitly assumed to be both encased and sound knots but there is nothing in the definition that requires either of those assumptions. See knot for further discussion.

pinned --- see pinned joint

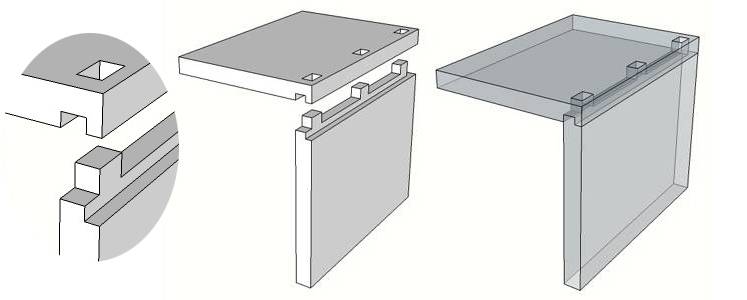

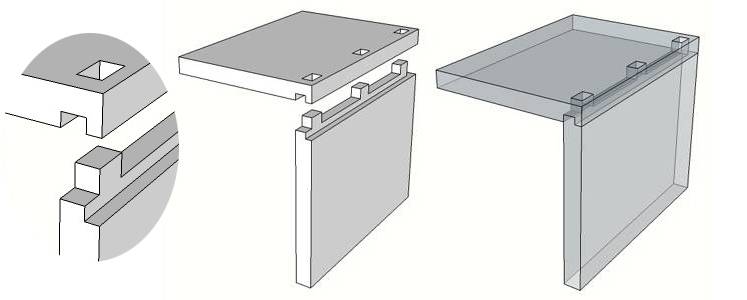

pinned case joint --- A complex case joint that is something like a multiple mortise and tenons along with a dado. Best described by illustration, so here you go:

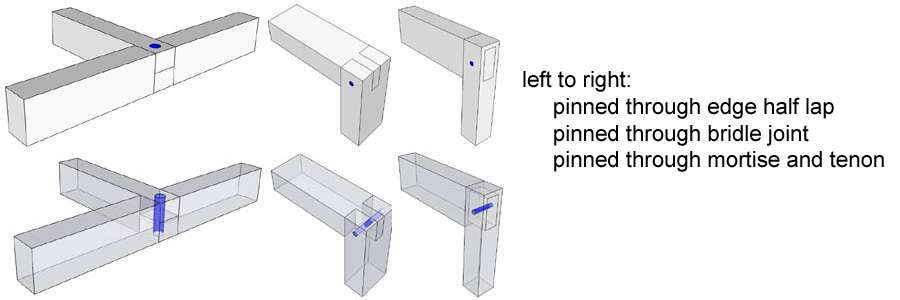

pinned joint --- (1) when used with "mortise and tenon", the term pinned is normally synonymous with "tusked" but can also be used in sense #2 as defined below; see tusked mortise and tenon

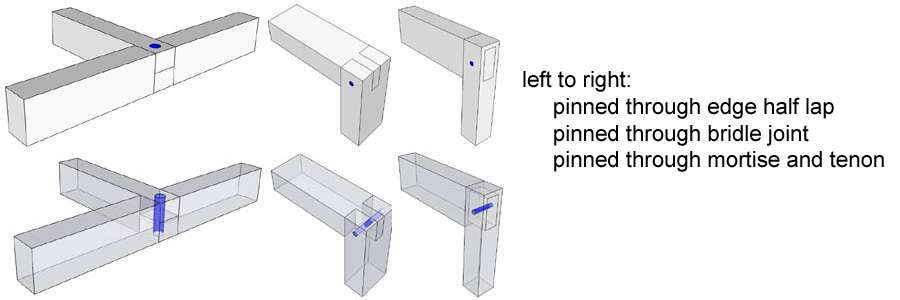

pinnedjoint --- (2) Refers to joints that have a dowel pin or other type pin inserted for extra holding power. Although the pin may go all the way through the joint (as in all of the examples below), it is often stubbed short of the front face. Examples:

pinned mortise and tenon --- synonymous with tusked mortise and tenon but a bad choice of synonym since the term "pinned" has a different meaning for all other joints and in fact can mean something different than tusked for a mortise and tenon joint. See also pinned joint.

pinned tenon --- This actually has two distinct meanings, first as synonymous with tusked mortise and tenon and second the usage described with the term pinned joint, with a pin through the mortise and the tenon both, as shown in the illustration with the term "pinned joint".

pin router --- A router-and-table construction designed to provide repeatable routed patterns. I think this can best be described by laying out how you make and use a pin router, so here it is:

- Take a metal pin, say 1/4" in diameter and find a straight router bit of the same diameter.

- Use the router bit to rout a pattern or design into a piece of smooth faced plywood to a depth of about 1/2 the thickness of the plywood. As you'll see in a minute, the pattern has to be what you want as seen from the OTHER side of the plywood.

- (this is the hard part) Mount a router, somehow, above a decent-sized flat surface with its bit pointing downward and capable of smooth up and down motion; think of making the whole router be like the bit in a drill press.

- Drill a hole in the flat surface mention in the step above and insert the metal pin into the hole with a little less sticking up than the depth of the routed pattern in the plywood.

- Line up the center of the router bit with the center of the pin.

- Put the plywood with the routed pattern downward over the pin

- Attach a workpiece to the top of the plywood with double sided tape or nails/screws in a throwaway part of the edges.

- Cause the router to come down onto the workpiece so that the bit cuts into it.

- Move the plywood/workpiece over the pin so that all of the pattern gets traced out by the overhead router bit.

- What you end up with is the pattern of the template now cut into the workpiece.

- Repeat as many times as desired to obtain perfectly matched routed patterns.

I have seen upsidedown pin routers where the router is just put in a normal router table and the pin is lowered over the upside down template, but cutting where you can't see the bit is likely to be tricky and this form of pin router doesn't seem all that workable to me as a general-use pin router. Maybe it would be good for some specific types of cuts, especially if you can move the router into and back out of the workpiece through the edge.

pintle --- The "pin" portion of a pintle and gudgeon hinge. When used on ships rudders, the pintle is typically a U-shaped strap with the pin attached at the middle of the U, but in other applications, other types are used. Below are examples of the U-strap type and for the other two common types, see lag pintle and plate pintle.

pintle and gudgeon --- A hinge type that is widely used on ship rudders. Basically it is a pair of U-shaped straps with one (the pintle) having a pin pointing down off the end and the other (the gudgeon) having a hole at the end to accept the pin. The gudgeon is put on the stern of the ship and the pintle is put on the rudder. Although on ships the pair almost universally uses the "strap" style, other applications often use a couple of other styles, all of which are illustrated with the terms pintle and gudgeon.

pipe clamp --- (1) A type of clamp in which a metal pipe is used to separate the jaws, one of which is fixed and the other of which has a screw mechanism for applying pressure. This is exactly the same as a bar clamp except that bar clamps are typically manufactured to fixed sizes (1 foot, 2 feet, 3 feet) whereas one can use a pipe of any length. The jaw sections can be purchased from tool companies and the pipe from a local hardware store. Jaws with deep throats are available.

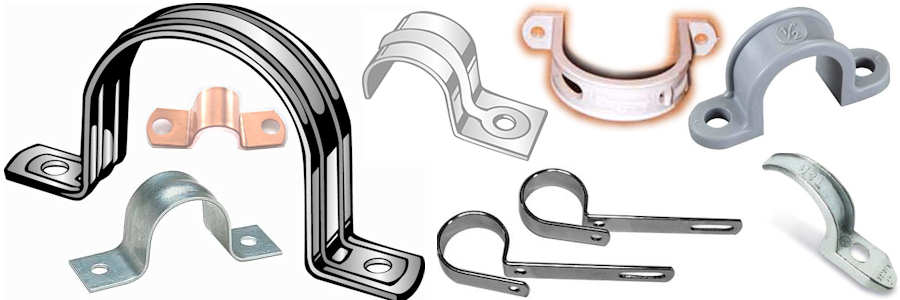

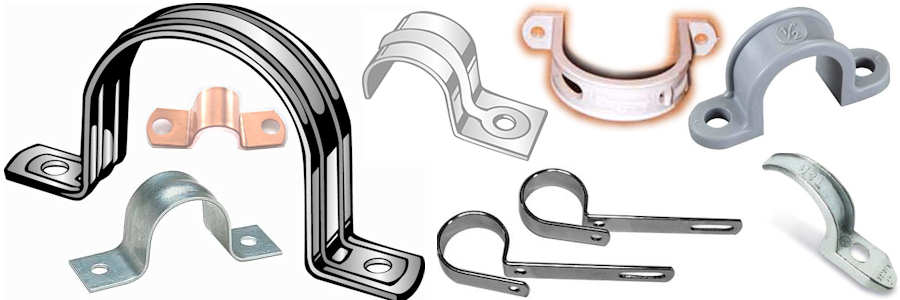

pipe clamp --- (2) A hold-down device that clamps a pipe to wood or masonry. Generally it is a half-cylinder with two flanges for screws, but may be only a partial cylinder with only one screw flange (in which case it is often called a pipe strap). There are numerous other devices that are called pipe clamps, and which DO perform various methods of holding down pipes, or holding pipes together, etc., but most are not related to woodworking or house construction as these are. The back of these pipe clamps / pipe straps may be ridged for extra strength. Examples for both definitions:

type 1 (portable vise)

type 2 (pipe clamp, ALSO used as a cable clamp)

pipe cutter --- A device that looks a little like a large C clamp but with a pair of rollers on the bottom and a circle of hard, wedge-edged steel on the part that presses down. You put a pipe in this, tighten the clamp a little, turn it all the way around the pipe, tighten some more, turn all the way around the pipe again, and continue this until it has cut all the way through the pipe. Examples:

pipe wrench --- A type of wrench that is used on pipes. It has two jaws that are adjustable via a knurled cylinder that moves the upper jaw in a direction parallel to the handle (normal pipe wrench) or perpendicular to it (offset pipe wrench), and the jaws have deep serrations so as to grab pipes firmly. Examples:

pippy --- A form of defect or character (depending on how you look at it) in wood figure where it looks as though the wood has a bad (or sometimes mild) case of the measles, with little spots dotting throughout the grain. Occurs in yew and a few other woods. In England, there is a form of oak burl that is called "pippy oak" in which the burl characteristics are pretty much the same as what we Americans call pippy, but more dense. Below is a pic of pippy yew, and to see more pics of pippy wood, click here: pippy pics

pitch --- (1) Although in woodworking this term is generally synonymous with resin, it usually refers to pine resin. In fact, there is a particular species of pine called "pitch pine" because it is particularly heavy in resin. Pitch is useful in caulking wooden ships to make the joints waterproof and it is the basis for the resin in the bag a baseball pitcher uses.

pitch --- (2) Synonymous with slope

pitch --- (3) see hinge pitch

pitch pocket --- An opening, extending parallel to the annual growth rings and containing, or that has contained, resin (pitch), either solid or liquid. This is considered a defect and it only occurs in softwoods that have resin canals.

pitch ratio --- In terms of what it means, this is synonymous with slope but it is expressed as a ratio instead of a percent so a 33% slope for example would be a 1:3 pitch ratio.

pitch streak --- An accumulation of pitch along a more or less regular streak in lumber. Also called "gum streak".

pith --- the soft core in the center of a tree trunk, branch, twig. The consistency of the pith is frequently punky. The pith in hardwoods is sometimes a cavity (open) while the pith in softwoods, is usually sound, albeit punky. If a plank completely contains the pith, that is called "boxed pith". See also chambered pith. Examples, including (1) punky boxed pith in catalpa, (2) hollow boxed pith in black ash, (3) very punky pith in stagnhorn sumac, and (4) moderately solid "ebony" pith in persimmon:

pith flecks --- Pith-like irregular discolored streaks of tissue in wood, due to insect attack (generally boring larvae) in the sapwood. They are called "pith" flecks because they usually have the punky consistency of pith, not because they are adjacent to the pith. Masur figure in birch is a form of pith fleck.

pith ray --- synonymous with medullary rays

pivot door hinge --- A type of hinge that is combined with a sliding mechanism so that you can open a cabinet door 90 degrees and then slid it back out of the way into the cabinet. This is mostly used in entertainment centers, armoires and kitchen cabinets. There is one type of this hinge that uses a a href="#rackandpinon">rack and pinon style mechanism and this is called, not too surprizingly, a "rack and pinion pivot door hinge". Examples:

pivot door runner --- The slide portion of a pivot door hinge.

pivot door slide --- This term is used to mean either a pivot door hinge OR the sliding portion of a pivot door hinge. Personally, I think it should just mean the slide portion, but I've seen it used both ways and I'm not here to make up definitions, just report to them.

pivot hinge --- (1) One type of scissor hinge

pivot hinge --- (2) see glass door hinge

pivot hinge --- (3) A type of hinge that is made for use with shower doors, doors in glass display cases, full-sized glass doors, and any other application where it is desirable (or necessary) to have the weight of the hinged object be taken up by a support on its bottom which also acts as the hinge. There are numerous designs, some include internal springs to close the door automatically. Those for glass doors generally have "U" shaped support brackets at the top and bottom of the door, at the edge that is to be hinges (see glass door hinge), with the (hinge) pin going up or down out of the bracket. For wooden doors, one design uses a heavy horizontal plate through which the pin projects. So the (hinge) leaves on pivot hinges are completly different that the more common type found on butt hinges. A feature that distinguishes this from the scissor hinge is that with this hinge, unlike with the scissor hinge, one (small) part of the item being hinged rotates in the opposite direction from the main body of that item. Examples:

plain bearing hinge --- a hinge with no ball bearings or oil-impregnated or anti-friction bearings

plain edge lap --- see plain lap joint

plain end lap --- see plain lap joint

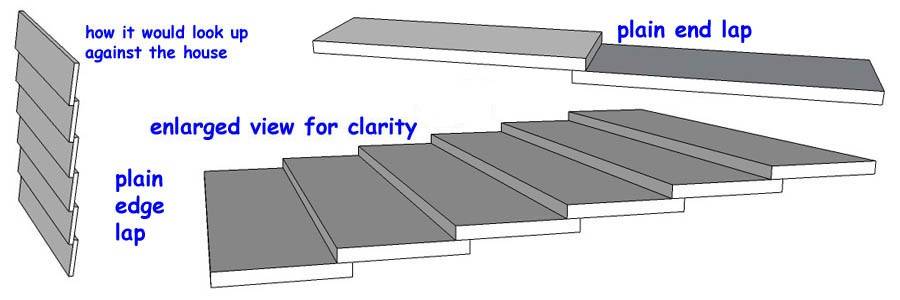

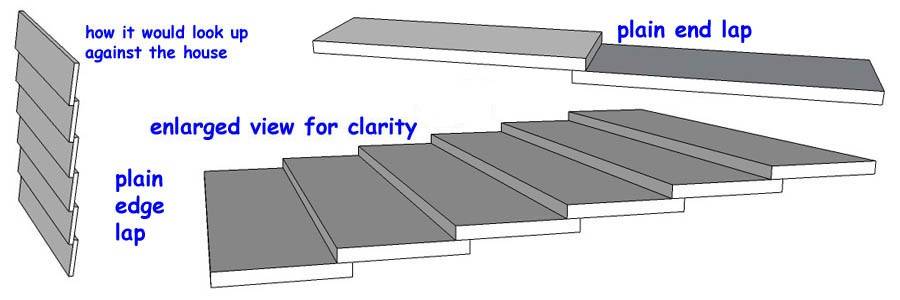

plain lap joint --- The most simple form of "joint" that almost isn't a joint at all. You just overlap the ends or edges of two planks. House siding is sometimes done this way. House siding would be done by lapping the long edges of planks, and would be called "plain edge lap" but you could have the ends lapped in the same way and it would be "plain end lap". For a slightly more complete version, see shiplap joint. Examples of plain lap / (edge lap shown as house siding):

plain sawn --- synonymous with flat cut

plain sliced --- A veneer production term meaning that the sheets were cut in a way that in lumber would be called flat cut and these veneer sheets have the same figure as flat cut lumber.

plane --- [verb] The process of removing material in thin shavings in order to make it flat or shape it in some way.

plane --- [noun] synonymous with hand plane

planed --- dressed to a smooth surface on a planer. Not to be confused with planned which means done with prior planning.

plane iron --- The cutting part of a hand plane. The bottom of the plane iron sticks out just a little beyond the plane's sole and its sharpened edge slices the wood.

planer --- [also "surface planer" and "thickness planer"] A stationary power tool with a long rotary cutting blade, or more commonly 3 knives mounted in a rotating cylinder. The blade housing is mounted over a bed and a rough-cut plank is fed under the blade and is thus smoothed down to a flat, even surface. Multiple passes are usually made so as to avoid chipping the wood by making an aggressive single pass. Interlocked grain on wood can make planing difficult and it is important to, as much as possible, make sure the grain of the wood does not point up into the blade. On some boards, the grain points up at both ends, so one end will HAVE to go through the planer with the grain in an undesirable direction; this often results in surface chip-out or tear. If a board is fed too fast through a planer, the resulting planer bite can cause a surface that is something like a washboard or waves in the ocean; this is known as skip. Planers are normally floor-model machines with blades up to 15" long but there are bench models with blades up to 13". Planers are also sometimes called "thicknessers" because in addition to dressing the surface, they are also used to reduce a plank's thickness to a specified dimension. There is a manual tool that performs the same function, called a hand plane. Examples:

planer bite --- A planer is intended to "shave" one surface of a plank by rapidly cutting slight grooves in it, with the board fed through the planer slowly enough that the grooves merge into each other and give a flat surface. If the board is fed rapidly, the grooves may be distinguishable next to each other and this is known as washboarding. When the board bounces a little and one groove is deeper than the other grooves (with or without washboarding) this is known as planer bite.

planer knives --- The blades (usually in sets of 3), that do the cutting in a planer. Examples:

planer mill --- The facility where lumber is planed, graded, and sorted. It may be part of a sawmill or it may be a separate facility that gets its raw material (rough lumber) from a sawmill.

planing --- The process of using a planer to shave a rough surface on a plank down to a smooth, even surface.

planing cut --- The cut made by a skew chisel on a wood lathe when it is used in its "standard" way with the edge at about 45 degrees to the edge of the turning spindle just above the the centerline. The cut made is very similar to that made by a hand plane, thus the name.

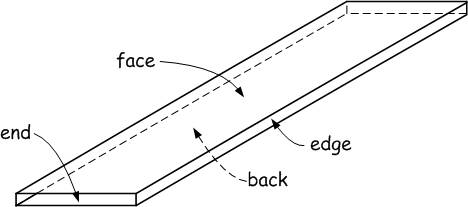

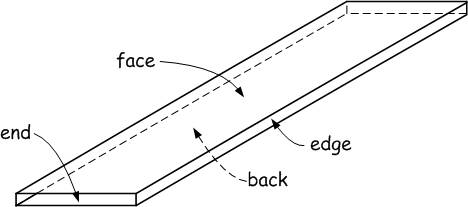

plank --- Like a board, a plank is a long rectangular-shaped piece of lumber that has been sawn from a log. What is a plank and what is a board? Many definitions just skip the question and say that board and plank are synonyms but most say a plank is a thick board and I've seen one that says that a board is a thin plank. That is, there does seem to be a consensus that "plank" carries a connotation of thicker than "board". For example actors can "trod the boards" in a theater because floor boards are supported and don't need to be too thick, but pirates make you "walk the plank" because if they made you "walk the board" it would probably break before you got to the end and pirates hate fixing things. Here's a drawing with the "parts" labeled:

All definitions seem to agree that both are long relative to their width and I have seen definitions that say that in order to be a plank, there is a width minimum of 3 inches. Others say 6 inches. Others say 8 inches. In thickness, some say a minimum of 3/4", some say 1 1/2", some say 2". For board, I have seen definitions (including that of the ASLS saying that it has be be under 2" thick and others say under 1 1/2" thick. Personally, I think it should be that planks are at least 1 1/2 thick and 6 inches wide except on odd days of the week when they can be any damn thing you want them to be (and keep in mind, we haven't even TALKED yet about slabs which add a whole 'nother dimension of confusion). In short, call it whichever one you like and if someone disagrees with you tell them I said it's OK and if they're not buying that, tell them to go to hell. See lumber sizes for other "sizes" of lumber.

plank flooring --- flooring made from wood planks. Plank flooring is almost always made from hardwood for durability, and is pretty much always installed using tongue and groove joints.

planking --- Planks laid side to side as flooring (on a boat, for example).

planned --- Done with prior planning; not to be confused with planed which refers to a smoothed wood surface.

plantation grown --- Woods such as teak that are grown on "tree farms" with the specific intent of being harvested for lumber.

planter --- A wooden container in which flowers (or, much less frequently, vegetables), are grown. These can be rectangular or hexagonal or other shape and may have straight sides but often have side that slope outwards from the base to the top. Often made of redwood or Western red cedar because of the decay resistance of those woods, a consideration that is important since planters necessarily contain moist soil. Non-rectangular planters often use a bird's mouth joint. Examples:

plaque --- A log section that has been cut at an angle less than 90 degrees to the axis and which therefore has an elliptical shape, usually with the bark left on and usually from one to two inches thick. Such shapes are very popular among craftsmen for making clocks and are similar to cookies. Examples:

plaster --- [noun] A mixture of lime or gypsum with sand and water. It hardens into a smooth solid but has enough working time to allow smoothing out with a trowel. It is used to cover walls and ceilings and was the primary material for such prior to the advent of drywall. See lath.

plaster --- [verb] Literally, it naturally means "to apply plaster (see noun definition above) to", but more figuratively it is used in the sense of to apply heavily or liberally, as in "the politician plastered the town with his posters".

plaster and lath --- see lath

plasterboard --- synonymous with drywall

plasticity --- The property that describes the ability of wood (or any other material) to return to its original shape after having been deformed in some way (typically by bending).

plastic wood --- synonymous with wood putty

plat --- A map of a piece of land showing its boundaries, length, width and any easements. All residential properties have a plat on file as part of the ownership records of the property. A plat can also refer to the map of a wider area such as a town.

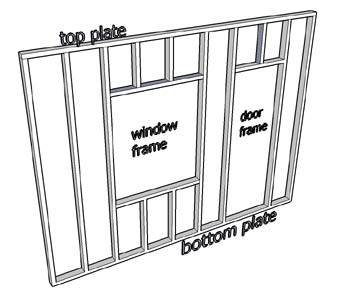

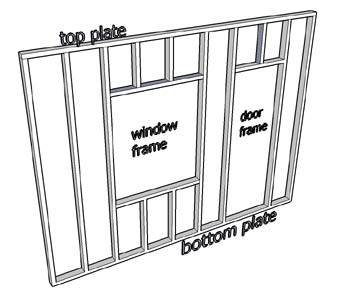

plate --- (1) In wood frame construction, the horizontal lumber member on top and/or bottom of the exterior wall studs which ties them together and supports the studs (the bottom plate) or rafters (the top plate). Also used as a general term for any horizontal framing member laid flat. Top plates are often double thickness (that is two two-by-fours face nailed to each other).

plate --- (2) The steel body of a circular saw blade onto which carbide teeth are welded.

Examples of defn (1):

plate joiner --- synonymous with biscuit jointer

plate joint --- synonymous with biscuit joint

plate pintle --- A particular type of pintle in which the mounting portion is a flat plate. Examples:

plate washer --- A heavy duty washer, usually square but sometimes round, that is used in attaching a sill plate to the foundation. Examples:

platform framing --- The standard modern method of house framing in which the outer wall studs go up only one story at a time and the entire 2nd story is built on top of the "platform" of the first floor construction. Compare/contrast to balloon framing.

platter --- A very shallow, flat bowl, with a diameter significantly larger than the height. Anything more than a couple of inches high is not likely to be called a "platter" and even that is high unless the turning is a couple of feet in diameter. Compare/contrast to other lathe turnings. Examples:

plenum --- The space above a dropped ceiling, such as that often found in kitchens but below the structural ceiling. The plenum provides space for the body and wiring of recessed lighting (such as fluorescent light panels), heating/cooling ductwork and possibly water pipes and electrical wiring.

pliers --- A small hand tool with two handles and two grasping jaws, working on a pivot between the handles and jaws. The characteristics of the jaws and the pivot style define the type of pliers. The "standard" pliers that are what most people mean when they say the word are formally called gas pliers or slip joint pliers and they typically have two positions in the pivot and serrated jaws about 1/4" by 1/4" in surface area that close flat on each other, with a further serrated curved area behind the jaw head for gripping nuts, pipes, etc. They also have, as do many other types of pliers, a small cutting area used to cut wire or other small metal things. Another common type is the needle nose pliers which have a single pivot and long narrow jaws; these are primarily used for electronics work. Many types of pliers may or may not have insulated handles; some (linesman's pliers) always do and some (locking pliers) almost never do. There are many other types of pliers (see below) used for numerous operations of holding, squeezing, cutting, twisting, and bending objects.

common

Pliers differ from wrenches in that pliers squeeze and wrenches do not. Pliers are sometimes able to do the job of a wrench, since pliers can apply rotational force, but wrenches do not work as pliers because they don't squeeze. Types of pliers:

- adjustable joint pliers --- same as channel lock pliers

- bent nose pliers --- similar to needle nose but with curved jaws

- brad squeezer --- for gently inserting brads

- channel lock pliers --- they open wider than slip joint pliers

- combination pliers --- same as linesman's pliers

- crimping pliers --- with wire strippers

- diagonal cutters --- wire cutting tool

- dikes --- same as diagonal pliers

- fence pliers --- used in making/mending fences

- gas pliers --- same as slip joint pliers

- locking pliers --- can be locked onto things

- linesman's pliers --- used in electrical work

- needle nose pliers --- mostly for electrical work

- pincers

- pump pliers --- same as channel lock pliers

- side cutters --- same as diagonal pliers

- slip joint pliers --- "standard" pliers

- tongue and groove pliers --- same as channel lock pliers

- Vise Grip pliers --- the original brand name of locking pliers

- water pump pliers --- same as channel lock pliers

- wire snips --- see diagonal cutters (flush sided)

plough --- [noun] A dado cut but made along the grain to receive the edge or end thickness of another member to form a joint. The same cut made across the grain is called a dado), and that name (dado) also includes plough cuts. A plough along the very edge of a plank is also called an edge rabbet. Although I have not included them as separate terms in this glossary, a plough can be half blind, blind, or through. For further explication of joinery grooves, and for illustrations of ploughs, see JOINERY GROOVES.

plough --- [verb] To make a plough cut (see noun definition above).

plough bolt --- synonymous with plow bolt

plough cut --- see plough

plow bolt --- A carriage bolt but with the additional requirement that the head be countersunk; designed to be used in the fabrication of plows. Examples:

plug --- A section of dowel that is inserted into deeply countersunk screw holes then cut off and sanded flush to hide the screw head. Plugs are sometimes used to simulate a pegged look [see dowel joints such as was common in older furniture.

plug cutter --- A type of power drill bit specifically made for cutting plugs. There is a longer version that is for cutting tenons, called, appropriately enough, a tenon cutter. Examples:

plugged core --- This refers to veneer core plywood where the inner plies can have a low grade (meaning a fair amount of flaws). APA standards state that gaps between pieces of core in this plywood should not exceed 1/2-inch.

plumb --- [noun] A term used to describe something that is perfectly perpendicular to the earth relative to gravity. A plumb bob on the end of a string will give you a line that is plumb or straight up and down.

plumb --- [verb] To measure the degree to which something is off of a plumb line.

plumb bob --- A weight on the end of a string, used to create a plumb line so as to measure the extent to which something (a tree, the corner of a house) is off of gravitational vertical. They're usually made out of brass, I think just cause brass looks so good; some are made of steel. They usually have a pointed end on the bottom and a screw cap in the top and you feed a string through a hole in the screw cap and then tighten the screw cap back down on the end of the string that's inside the bob and the string then is in line with the center of gravity, so that when you hold the other end of the string up in the air, not only do you have a string that shows you true vertical, you also have a pointed end that is directly below the top of the string. Examples:

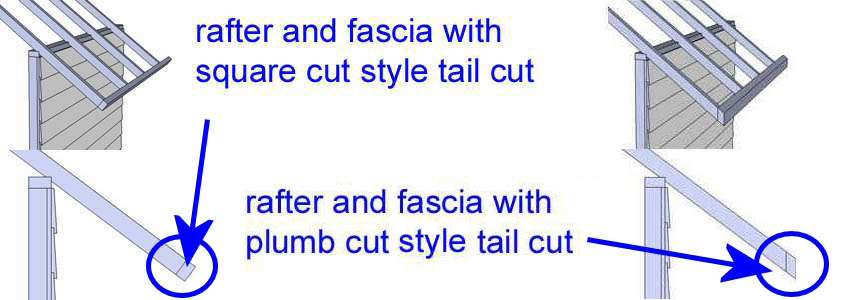

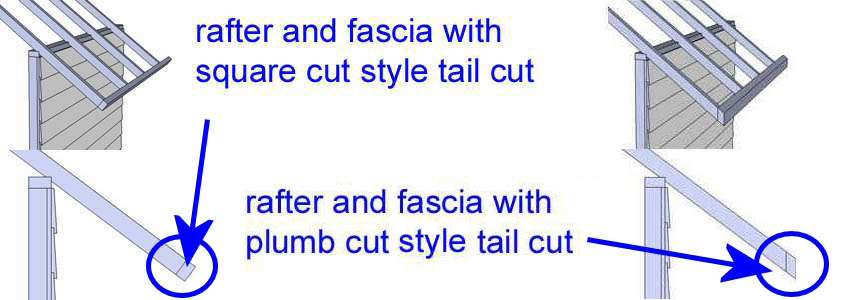

plumb cut --- The tail cut on a rafter when it is cut off in a vertical line (a plumb line) rather than perpendicular to the edge of the rafter, which is called a square cut. Examples:

plumbing vent --- A term used to describe a plumbing pipe that projects through a roof plane.

plume --- see feather crotch

plunge cut --- In lathe turning, pushing the lathe tool straight into the wood. Compare/contrast to sweep cut.

plunge router --- A router mounted on a spring loaded base. The router can be turned on and plunged down into the workpiece. This is very useful for doing routing where you don't want the edges of a piece to be routed. Examples of such uses would be routing lettering into a surface or making the insertion cut for a blind dado. Examples:

ply --- One layer of any laminated construction. See plywood.

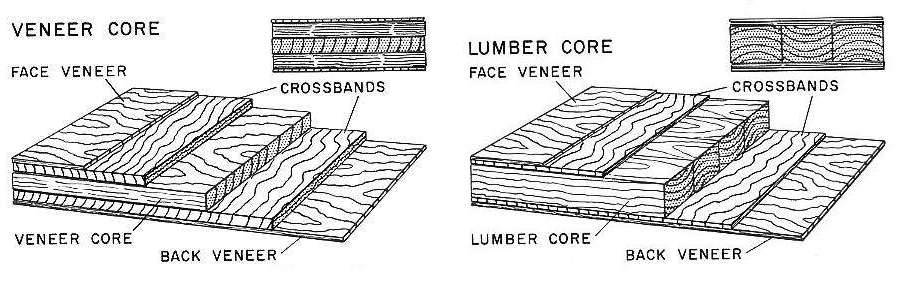

plywood --- a flat piece of construction material that is made up of 3 or more layers of wood of one kind or another bonded with adhesive. Plywood is generally sold in 4-foot by 8-foot "panels with the thickness ranging from 1/8" to 3/4". The outer layers will normally be solid wood veneer sheets of varying thickness and with quality ranging from very poor to very high and the grain of both sheets running parallel to the long direction of the panel. Depending on what the inside of the panel is made of, the plywood will be named veneer core plywood (solid wood plys), lumber core plywood (strips of wood inside), particleboard-core plywood (particle-board interior), or even foam core plywood. Where the inner portion of plywood is made of solid thick veneer sheets of wood, the sheets are placed in alternating layers of oppositely-oriented grain, which provides for equal strength in all directions and great stability with no tendency (or even ability) to split the way lumber can split along its grain. For such laminations, it is normal to have an odd number of plys and for all types of plywood, it is normal to have the grain on both outer plys running parallel to the long edge of the panel. When lumber strips are used as the interior, they are placed with alternating grain direction so as to minimize the tendency to warp.

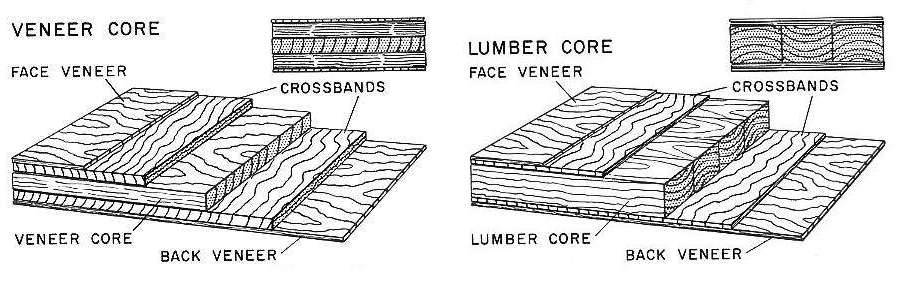

Regardless of what is used in the interior, the plies are bonded together with adhesive of one sort or another, depending on the intended use of the plywood. For example, exterior grade plywood will be bonded with a waterproof adhesive. Heat and pressure may be used in the bonding process. Most plywood, especially construction grade plywood, is made from softwoods, but architectural panels may be made with outer layers of hardwood. The veneer sheets for inner plys of veneer core plywood are typically 1/4" thick softwood and are produced on a veneer lathe using a rotary cut (see that term for an illustration of the veneer lathe). Veneer core and lumber core plywood panel construction is shown here:

plywood diaphragm --- Plywood sheathing/bracing on floors, roofs, or walls; provides shear strength to resist wind and earthquake loads.

pneumatic --- see pneumatictools

pneumatic drill --- Synonymous with jackhammer.

pneumatic drum sander --- Unlike most tools that carry the appellation "pneumatic", the pneumatic drum sander does so not because it is POWERED by air pressure but rather because it is a type of drum sander that has a sleeve that is held rigid by air pressure, and which can therefore be made soft or hard depending on the needed application. Pneumatic drum sanders are far more flexible in sanding curved parts than are the various rigid-drum styles. The tool may be either bench mounted or floor mounted, and many commercial types have a buffing wheel mounted on the other side of the arbor. Compare/contrast to other forms of power sander. Examples:

pneumatic tools --- pneumatic tools (aka "air tools") are tools driven by compressed air rather than electric motors. This as the advantage that the tools are lighter than comparable electric-power driven tools because they do not need the heavy electric motor of such tools. The bad news is that they require a good-sized (and very noisy) air compressor to generate the motive force. Because of this, and the need to have air hoses all over the shop, these tools have traditionally been very sparsely used in DIY settings but their reliability and light weight have long made them staples of industrial use. When was the last time you saw an automobile garage mechanic remove a tire lug with an electrically powered device? Most likely never.

pocket rot --- Localized advanced decay that occurs in the form of a hole or pocket, usually surrounded by wood that appears to be, and in fact usually is, sound.

pocket screw hole --- A hole drilled at a sharp angle into a board or panel to allow it to be screwed to another piece of material, generally at a 90 degree angle. This is a popular joinery technique and there are commercial jigs called pocket screw hole jigs to facilitate it. This hole is normally put at a place on the workpiece that will be hidden from view in normal usage of the piece.Examples:

pocket screw hole jig --- A jig, generally manufactured (although some woodworkers do make their own) that facilitates the uniform drilling of pocket screw holes. Because of the sharp angle, these holes are pretty much impossible to drill freehand, so these jigs are quite useful. Examples:

pocket stone --- Any sharpening stone that is small enough to be carried in ones pocket. A person using a scythe out in the field might carry a pocket stone to touch up the blade without having to go back to a far off building to do so.

point --- Same meaning as in general English usage; a sharp end on something. In woodworking, it particularly refers to the sharp end of a nail or screw, but also to the sharp end of many tools such as an awl. On nails, the point is often deliberated blunted because a blunted point will crush its way into the wood, which SOUNDS like a bad thing but has the happy result of not pushing the wood fibers aside (as a sharp point would) which is good because pushing the fibers off to each side of the nail can cause the wood to split.

point load --- A concentrated load, such as would be found at the base of load bearing vertical beam. Compare/contrast to uniform load.

pointside --- The piece of wood in a joint that receives the point of a nail or screw after that fastener passes through the headside.

pole --- A long wooden cylinder, typically with a length that is many times its diameter, made from a tree trunk or branch.

pole lathe --- An old-style human-powered lathe used for spindle turning green wood. The operator pushes a treadle down with his foot and this bends a long springy pole that is attached to the treadle by a rope and it is the spring action of the pole that returns the treadle to the up position ready for the next downward push from by the operator. Such lathes require different style tools than a powered lathe. They have been in use for thousands of years but are today a very rare hobby tool in the industrialized countries, not used commercially since about WWII.

pole stand --- A stand of trees whose average DBH is between 4 and 10 inches.

pole timber --- Trees 4 to 10 inches DBH.

polish --- (1)[verb] To remove a small amount of material from the surface of an object so as to make the surface smooth and shiny. This is the action of a super-fine grit sharpening stone of the type called a polishing stone. See also grind / hone / polish.

polish --- (2)[verb] To use pressure to smooth out a surface and make it shiny. This is the action of rubbing the cured surface of a finishing agent with a fine cloth so as to remove grease or dirt from a surface and to make it shine.

polish --- (3)[noun] A finishing agent that provides a hard, smooth, surface on an object, sometimes on top of another finishing agent.

polish --- (4)[noun] The degree of shine that an object has by virtue of being polished (see verb definition above).

polish --- (5) The only word in the English language that is pronounced differently when capitalized (as in "the Polish lady used wax to polish the table").

polishing stone --- A sharpening stone with extremely fine grit. These stones remove very little metal and provide such a fine grind that they polish more than sharpen.

polyethylene glycol --- [PEG] A chemical with a huge number of applications/uses. As regards woodworking, it is used as a stabilizing agent in place of conventional seasoning processes to treat green wood. It replaces the water in the wood which makes the wood dimensionally stable and prevents warping or shrinking. It is widely used by wood turners to stabilize green wood for turning.

polyurethane --- A chemical compound (technically, a polymer containing urethane links, whatever that means) that is widely used as a finishing agent in woodworking. It has good resistance to mechanical wear and a relative strong resistance to chemical staining. Various versions come in any desired degree of gloss from very low to very high, and formulations are available that contain ultraviolet blockers to protect the color of wood. Compare/contrast to other finishing agents.

polyvinyl chloride --- [PVC] A very tough, wear resistant type of plastic widely used in electrical wire insulation and home water pipes. The white plumbing tubing you see at your local hardware store is PVC pipe.

pomelle --- [Spelling variations include "pomele", "pommelle", "pomelle", and "pomele"] --- A type of wood figure that resembles a puddle surface during a light rain: a dense pattern of small rings enveloping one another. Some say this has a "suede" or "furry" look. It's usually found in extremely large trees of African species such as sapele, bubingaand makore. Some domestic species with a sparser, larger figure are referred to as blister. The term is not used totally reliably and you may encounter some confusion among the terms "blister", "pomelle", and quilted from different vendors. The name Pomelle comes from the French word for "quilted", so it's not too surprising to find this confusion. In sapele, there are even more confusing names used for variations among figure types including pomelle, so you may see "pomelle pebble", "pomelle swirl", "pomelle quilted" and other combination terms that are not necessarily used consistently among vendors. Below is a composite pic showing sapele with a heavy pomelle figure, African mahogany with a medium pomelle figure, and makore with a weak pomelle figure that most vendors would classify as blistered. To see more pics of pomelle figured woods, click here: pomelle pics.

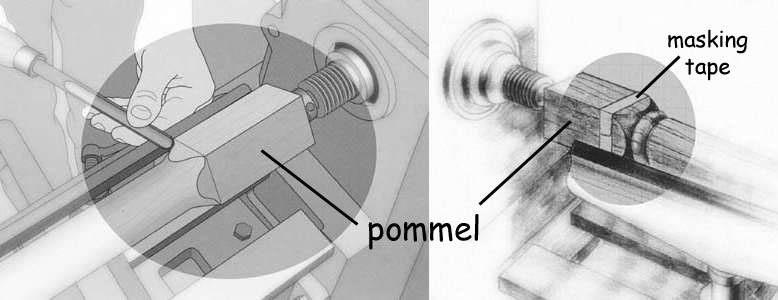

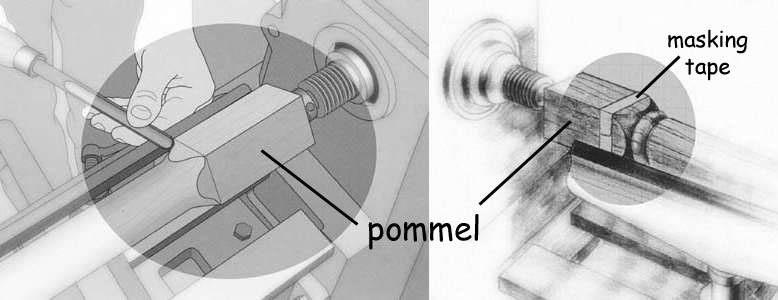

pommel --- A square shoulder left on the end of a spindle turning; commonly done on table legs, balusters, and other items. When doing the round sections of spindle turnings, you can rough turn the blank and then use a pencil on the spinning blank to mark places for particular cuts, but since the pommel has to stay square, you can't do that, so what turners commonly do is put masking tape on the blank to show exactly where to cut the shoulder for the pommel and transition down to the round section. NOTE: some (few) definitions of this term do NOT consider it to mean a square section as described here but rather the TRANSITION portion between the round section and the square section. Examples:

pop --- A term used by woodworkers to describe the sometimes extreme way that wood figure will be caused to stand out strongly when a finishing agent is applied. For some (but not all) woods, this will occur almost no matter WHAT finishing agent is used and for some it happens more with some agents than others (wax finishes never give the kind of pop that some of the others do), and in any case it is one of the joys in the creation of wooden items to have gone through all the effort of cutting and assembling and sanding the item and then to see the grain pop out and greatly enhance the beauty of the wood. Exotic woods that are being photographed for sale are very often moistened so that the grain will pop for the photograph. It should be noted that NOT all wood figure pops with the application of a finishing agent ... sometimes the figure can actually be made more subdued (often called "muddied") as shown in the composite pic below which shows poped figure on three woods and then muddied figure on Bermuda cypress. Examples:

pore --- The cross section of a hardwood vessel. Pores figure strongly in the appearance of the grain in hardwoods (softwoods don't have pores).

Woods with large open pores are difficult or impossible to bring to a fine finish unless some sort of filler is used. Many hardwoods have tiny pores (that is, they have tiny-diameter vessels) and thus can be brought to a fine natural polish.

porosity --- In standard English, this refers to the ability of something to pass gas or liquid, but in wood it refers to the size and openness of the pores and is NOT a measure of ability to pass fluids (permeability is the correct term for that).

porous --- In standard English, this term is used to characterize a material that readily passes fluids, but as regards to wood, it means having large pores and is NOT a comment on a wood's ability to pass fluids. (permeable is the correct term for that). Red oak, for example, has large open pores and thus is highly permeable and a terrible wood from which to build containers for liquids, whereas white oak also has large pores, but they are filled with tyloses, which means white oak is NOT permeable, and thus is very suitable for use in making containers for liquids.

portable circular saw --- Usually just called a circular saw, this very versatile portable power tool is a workhorse in the construction trade because it can be carried up on rooftops and other places where if you didn't have it you would have to lug a piece to be cut down to where there was a stationary saw and then back up again. It is basically a portable table saw, with less precision but excellent versatility. It can be found in various sizes starting at 7 inches for the blade diameter and it also comes in battery-operated models. An adjustable base plate allows it to do angled cuts and also allows setting the depth of a cut. Examples: