The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

D2S --- Dressed 2 Sides; synonymous with S2S

D4S --- Dressed 4 Sides; synonymous with S4S

dado --- (1) the lower section of an interior wall, generally from about waist high (or at the point of a chair rail if there is one) down to the baseboard. The material used to cover this area, if different than the upper part of the wall, is called wainscoting.

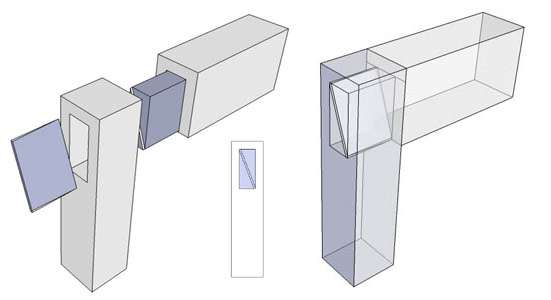

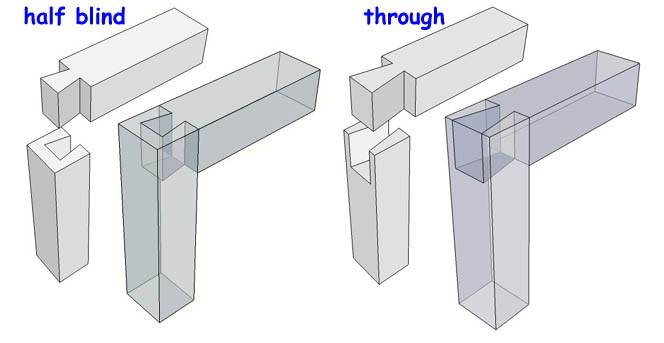

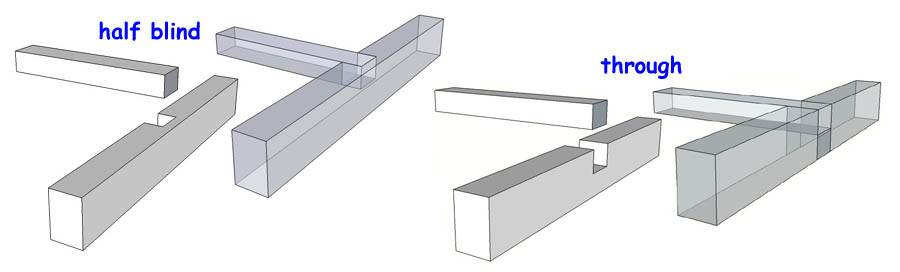

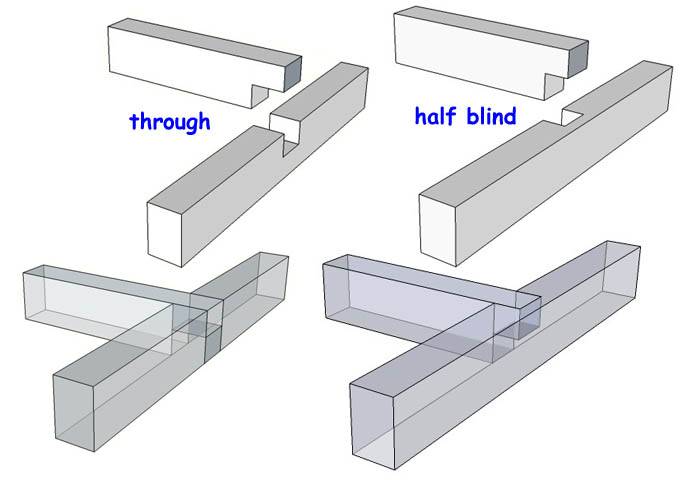

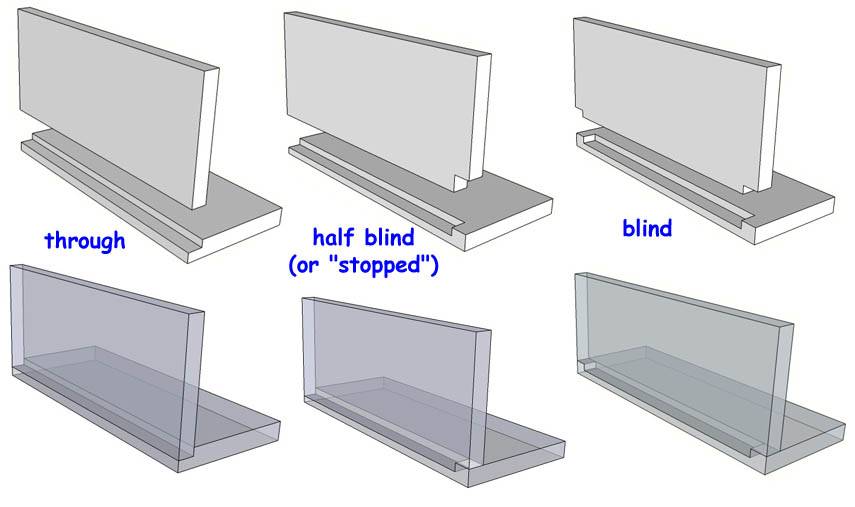

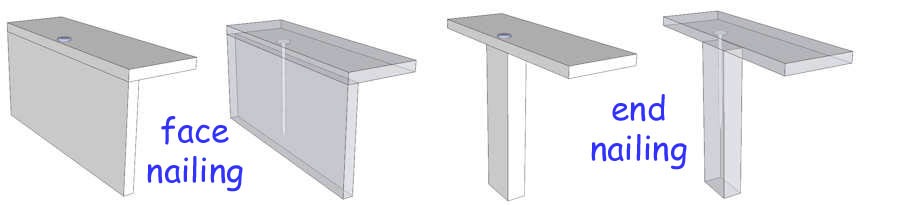

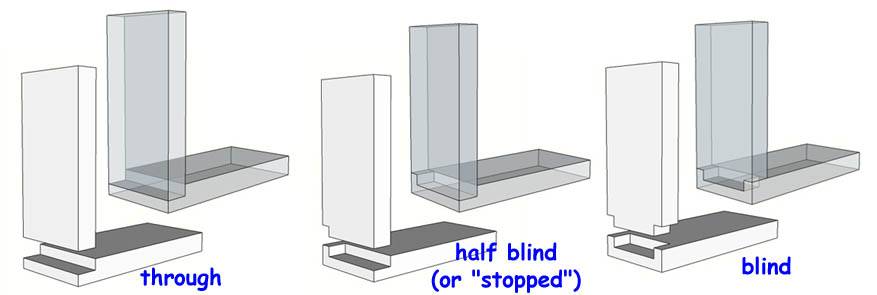

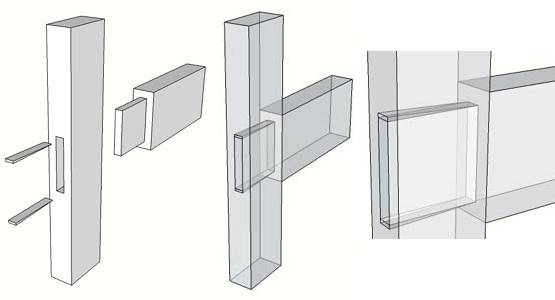

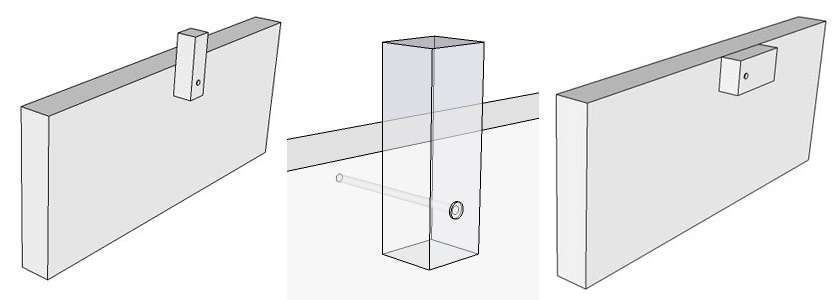

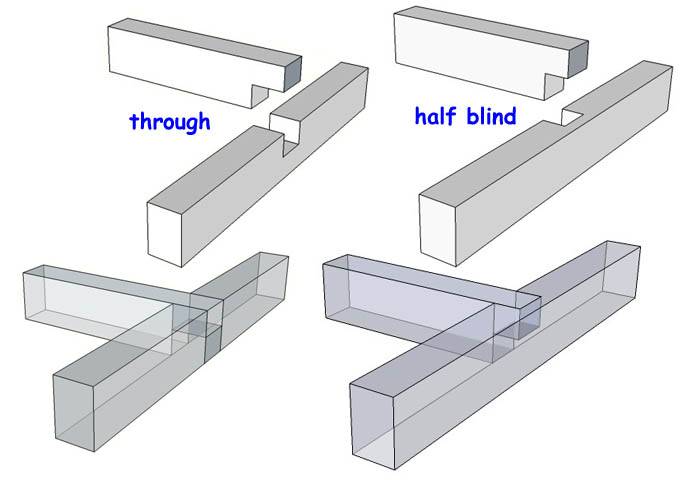

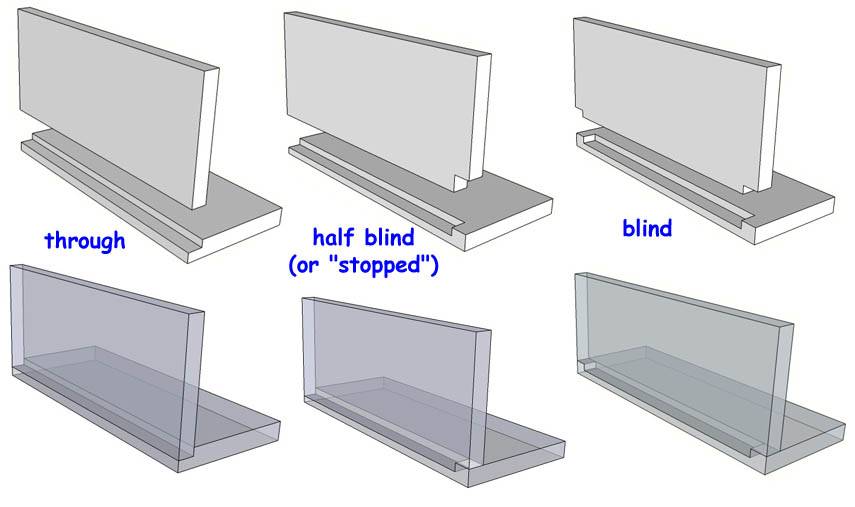

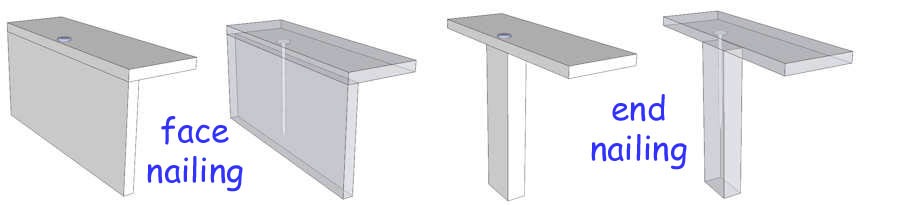

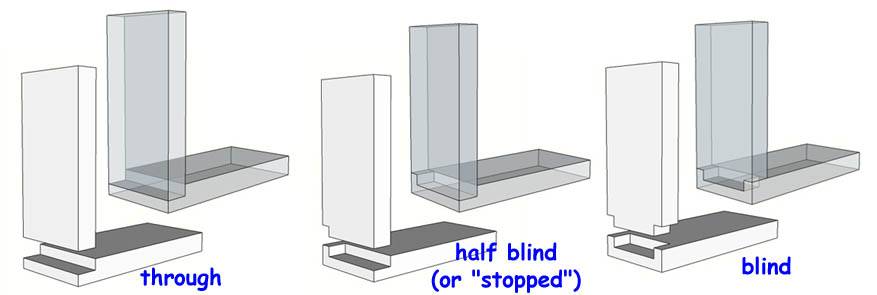

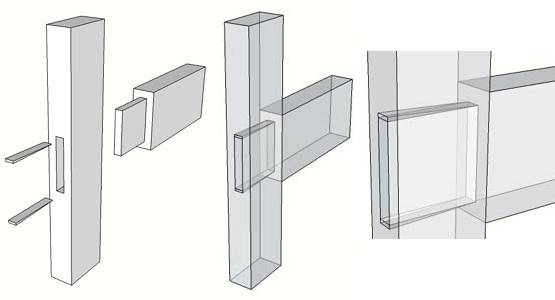

dado --- (2) A rectangular slot cut across the face of a plank, perpendicular to the grain, so that an end or edge of another plank can be inserted to form a load-bearing joint. If the cut is made at the end of a plank, the cut is called a rabbet (or more specifically an "end rabbet" If such a cut is made with (parallel to) the grain it is called a plough cut and if it is made parallel to the grain at the edge of a board, it is called a rabbet (or more specifically an "edge rabbet"). Joints made with dado cuts are classified depending on whether the dado cut goes into both edges (through dado), only one edge (half blind dado), or neither edge (blind dado). For illustrations, see JOINERY GROOVES and those three terms for which the URLs were just given.

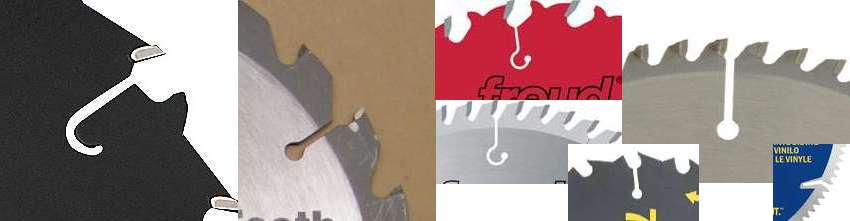

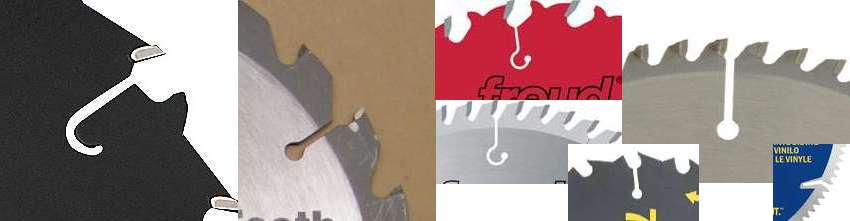

Because dado cuts are so commonly done in cabinetry and carpentry, and because they cannot be made with a single pass of a normal saw blade, special blades, called dado cutters have been created and are readily available for the woodworker. These come in two forms, the adjustable dado blade and the stacked head dado cutter. Dado cuts are also commonly made with routers.

dadocutter --- see stacked head dado cutter and adjustable dado blade

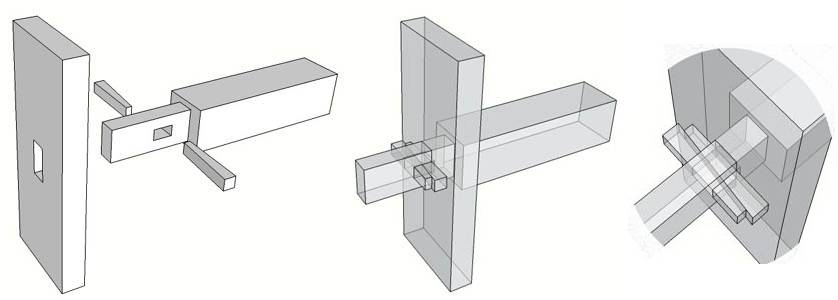

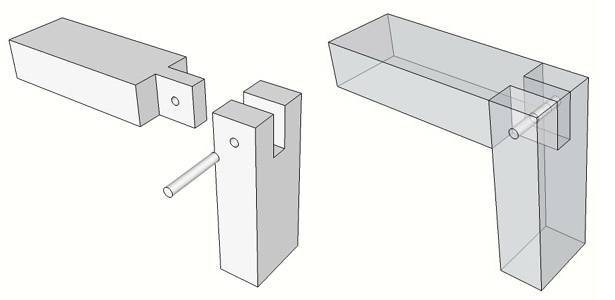

dado joint --- A joint made using a dado cut. There are numerous styles, including the following which are illustrated in this glossary. For further explication of joinery grooves, see JOINERY GROOVES.

dado rail --- synonymous with chair rail

DBH --- Diameter at Breast Height

DC --- Direct Current

deadblow hammer --- A hammer, usually made of plastic, with a hollow head that is partially filled with steel shot or sand. As the head is moved towards the object to be struck, the shot moves to the rear of the head and when the head is stopped by the struck object and starts to rebound, the shot moves to the striking end of the head and greatly reduces or even totally prevents the rebound, thus providing a more controlled blow than one gets with a normal hammer. This is particularly useful in, for example, dislodging metal parts where the rebound could possibly be dangerous. Deadblow hammers are not used for driving nails. Examples:

dead center --- [noun] A lathe center that sits in either the headstock spindle or the tailstock spindle of a lathe. In the headstock spindle, this would generally be a spur drive or a Steb drive but in the tailstock spindle, it might be a cone center or a cup center. The primary characteristic of the dead center is that it does not have any roller bearings. Compare/contrast to live center.

dead center --- [adjective] Exactly in the center

dead load --- The total fixed weight that a support structure is required to carry, such as permanent fixtures, plus the weight of the structure itself. Compare/contrast to live load.

dead nail --- In days gone by, screws were either not invented yet or hard to come by, but nails were available, so certain types on construction were give the necessary holding power by driving a nail through the connecting items and then bending the pointed end over at the back. Such nails were then referred to as "dead" nails, and the phrase "dead as a doornail" referred to such a use in a common type of door construction.

deal --- A vague, ambiguous term used to describe softwood planks. Most reports say that deal is softwood timber measuring between 2 and 4 inches thick and 9 and 11 inches wide. Some reports say that deal is limited to pine and fir and some say it is limited to any softwood that is easy to saw.

debark --- To remove the bark from trees or logs. There are two main types of debarkers: rosserhead and ring debarkers. I have not yet researched these.

decay --- synonymous with rot

decayed knot --- A knot that, due to decay, is softer than the surrounding wood and may have noticeable voids. These knots are not allowed in many construction and other service situations because they reduce the structural integrity of beams and they reduce the weather resistance of planks. A decayed knot may be either intergrown or or encased but is clearly unsound. Examples:

decay resistance --- The extent to which wood can resist the things that cause decay. Redwood, for example, is highly decay resistant but many woods are not.

deciduous --- As regards things woody, this term refers to trees (angiosperms) that have leaves that fall off every fall. Such trees are hardwoods, as opposed to conifers (evergreens) which are the source of softwoods. NOTE: Some gymnosperms are deciduous, e.g. bald cypress and larch, while many hardwoods in both tropical and temperate climates are evergreen.

decking --- Commonly used to mean an outdoor floor with railing (and often staircase) that provides surface for eating and/or relaxing outdoors right next to a house. This type of decking is most commonly made from pressure treated lumber. More widely, the term refers to material used to span across floor beams or joists to create a floor or across roof purlins to create a roof surface onto which the roof sheathing is fastened, or wooden planking next to a swimming pool, or the cross supports in a wooden bridge. See also decking timber.

decking timber --- A name specifically given to timber that is used in surfacing parts of ships, bridges, and other structures subjected to vehicular or heavy pedestrian traffic.

deck screw --- As the name says, this type of screw is designed for use in decks (external structures usually of treated lumber or very durable hardwood), thus they are made from galvanized steel, stainless steel, or are coated in some way to resists corrosion. The have very coarse threads and sometimes have a section at the top that has cylindrcial ridges rather than sprial threads; this is to resist pull-out due to expansion/contraction of the wood (once the screw is driven, the wood fibers push back around the ridges and not being helical, they strongly resist having the screw "undrive" itself due to wood movement). They are ALWAYS flat-headed and countersunk or have small heads (a type of trim screw) that will sit below the deck surface since it would be really obnoxious to have screw heads sticking up out of a deck. The drive type is normally either allen head or phillips head, never flat head because driving screws into decking requires a lot of torque and flat head drives are just too likely to strip. Sometimes, decking screws are a type of self tapping screw. Examples:

decorative --- In woodworking, as in standard English, the term means having to do with something that is designed to add attractiveness to an item, but in woodworking, it is also used to specifically contrast with the term "structural" which has to do with adding strength, not beauty.

decorative panel --- A plywood panel grade with rough-sawn, brushed, grooved or striated faces. May be interior or exterior type. Common uses include paneling, built-ins, accent walls, counter facings and displays. Exterior type uses include siding, gable ends and fences.

decorative veneer --- Veneer has many uses, some of the utilitarian, some decorative. Utilitarian is exemplified by the use of veneer to surface a composite material such that the combination of the veneer-on-composite produces, for example, a panel that looks like oak but is less likely to warp. A decorative use, for example, would be the use of a very fancy veneer for architectural paneling in the reception area of a corporate office, where it would be extremely expensive to use the solid form of the exotic wood and the same look can be obtained by using veneer. Rotary cut veneer of exotic woods is almost always intended for decorative use.

deep fluted gouge --- synonymous with bowl gouge; compare/contrast to shallow fluted gouge, which is synonymous with spindle gouge. That is, bowl gouges have a relatively deep flute and spindle gouges have a relatively shallow flute, thus the alternate names.

defect --- In wood terms, as in standard English, a defect means a flaw; something wrong with the wood. Defects generally degrade the appearance of the wood (and thus its value) and may also reduce the strength and/or durability of the wood. In woodworking, the term "degrade" is also used. The primary types of wood defects are:

deflection --- The amount of movement away from a straight line in a shelf, floor, joist, or counter caused by the weight it's supporting. When a horizontal beam sags downward due to a load, the amount of downward sag is the deflection. For a cantilvered beam, the deflection is the amount of movement of the end of the beam when loaded as opposed to unloaded. Think of a diving board. When nobody's on it, it sticks straight out, but when a diver jumps on the end, it deflects downward.

deflection limit --- The maximum amount a beam is permitted to deflect under load.

degrade --- In woodworking, degrade has the normal English-language meanings. In verb form it means to cause to be flawed and in noun form it means the type of flaw. See defect

dehumidification --- The process of removing moisture from the air. Kiln drying is a process that removes moisture from wood by exposing it to

heat and dehumidified air in an enclosed space.

delaminate --- To separate; said of the layers in a laminated construction when they separate due to lack of adhesion between plies or between the laminate and the substrate. See also delamination

delamination --- The condition that occurs when layers in a laminated construction separate due to lack of adhesion between plies or between the laminate and the substrate. By one of those remarkable coincidences that sometimes happen in life, when I was putting in this entry in the glossary, I happened to be in a motel room that had a small kitchen area and the counter top was a thin laminate over a particleboard substrate, clearly put there by contact adhesive that had recently failed. Since I take my trusty camera almost everywhere, I whipped it out, and here's my illustration for delamination:

delignification --- The removal of lignin from wood by chemical treatment as part of the process of making white paper products.

demarcation --- A term referring to the point of separation of two parts. In woodworking it is used to describe the boundary between heartwood and sapwood, and less often to describe the boundary between earlywood and latewood so you will see phrases such as "razor-sharp demarcation" meaning that the separation between the two is very distinct. It isn't always very sharp, as you can see in these examples of heartwood/sapwood boundaries. The zircote, cocobolo, and blackwood have very sharp demarcations and the black walnut and white oak have very vague demarcations and the rest of them are somewhere in the middle.

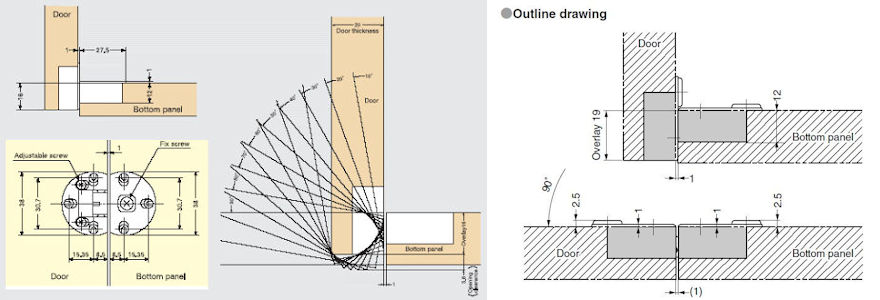

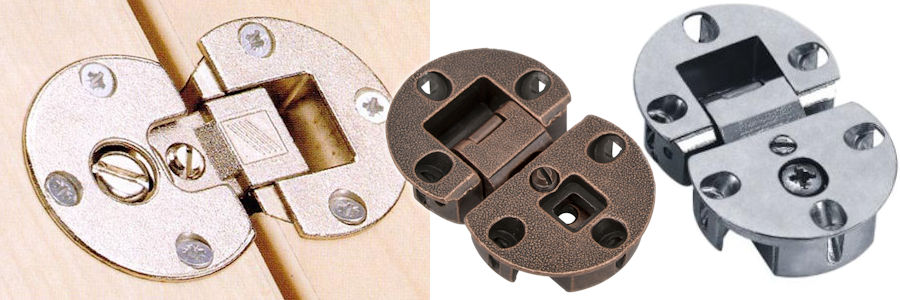

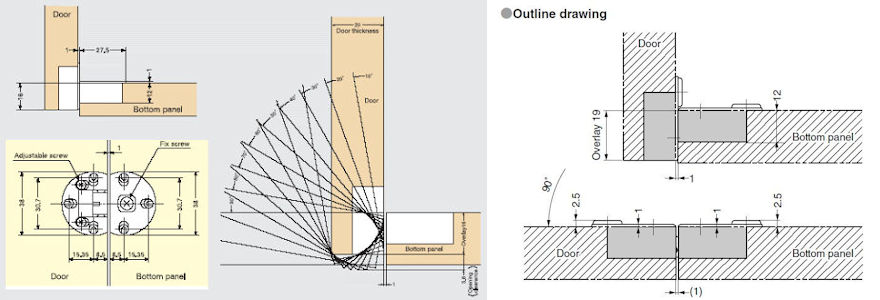

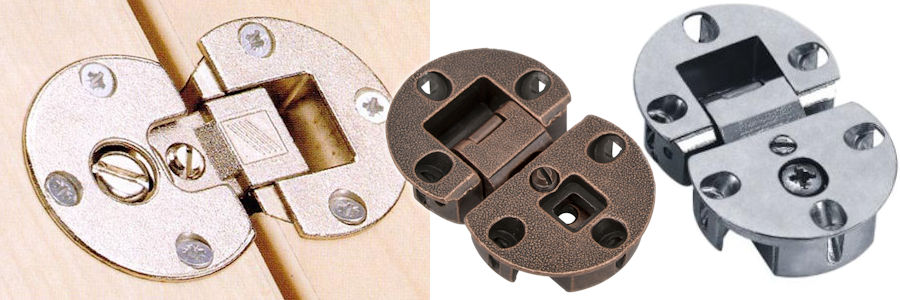

demountable hinge --- A specialty hinge that is used to facilitate the mounting and adjustment of cabinets, especially kitchen cabinets. There are two types: the double demountable hinge and the single demountable hinge.

demountable hinge slot cutter --- A router bit used to cut the slots needed by a demountable hinge tab. Examples:

denatured alcohol --- ethyl alcohol (that is, ethanol, or "drinking alcohol") with small proportion of chemicals (sometimes even poisonous) added to render it unfit for drinking; used as a fuel in spirit burners and camp stoves and as a solvent for cleaning and in shellac and some dyes. It is made toxic as a matter of public policy compromise due to the fact that it is useful as an industrial solvent, but relatively inexpensive to make and would otherwise compete with publicly taxed drinking alcohol. In some countries it has to be dyed red or purple.

dendrochronology --- A scientific method of dating objects based on the analysis of patterns of tree rings. Dendrochronology can date the time at which tree rings were formed, in many types of wood, to the exact calendar year. By using a technique of successive overlapping sections of different trees, where the overlapped sections are clearly of the same time period but one is in the middle of one tree and the other is in the outer area of another tree, it is possible in some areas to date wood back a few thousand years, or even several thousands. This can be used to calibrate radiocarbon dating and is also directly usable in dating some artifacts made of wood.

dense grained --- synonymous with tight grained

density --- [replaced by specific gravity in all modern texts) A measure of mass per unit volume. For wood, this is normally expressed in the USA in pounds per cubic foot and everywhere else in the world in kilograms per cubic meter. The mass of a given volume of wood is highly dependant on the moisture content (MC), so to be consistent, it is necessary to specify an MC as reference for the density. If no MC is specified, 12% is assumed, but that's not always a good assumption. Wood density will vary greatly within some species, less within others. In general, durability, hardness, and toughness usually increase with density. Wood density generally runs from about 20 pounds per cubic foot to about 80 pounds per cubic foot. Density is also called "absolute density" to distinguish it from relative density which is the absolute density divided by the density of water at 4 degrees Centigrade.

deprecated --- Refers to a term that, while still correct, has been replaced by another term that now has preference in use, so the use of such terms is disparaged. Example: relative density.

depth stop --- A mechanism on the side of a drill press that limits the travel of the quill. This allows both safe drilling to a known depth and repeatable drilling to a known depth.

desiccant --- A drying agent; a substance (e.g. calcium oxide) that has a great affinity for moisture and is used to remove such moisture from the air. Desiccants are often packed with ferrous tool parts so that they will not rust due to moisture from the air.

detail gouge --- This term is sometimes used as synonymous with "fingernail gouge", which is a a spindle gouge with a fingernail grind. However, there is a distinction that many manufacturers make, which is that the gouge they call a detail gouge has a more shallow cannel than a spindle gouge. The name "detail" comes from the fact that they are great for working on fine details in a spindle turnings. There is an even MORE shallow cannel version that is called a shallow detail gouge. See also lathe gouge shape comparison. The examples in the composite pic below include both spindle gouges with a fairly shallow flute and a fingernail grind, and also what are more appropriately called detail gouges because of their very shallow flute:

detailing --- A wood carving term referring to one of the final stages of relief carving when all the surface (background) decoration is carved.

detail sander --- A type of small hand held power sander that is used for getting into corners and small areas (thus the name "detail") as opposed to being designed for sanding large areas. These sanders always have a wedge shaped front edge. This specific "type" of sander overlaps with palm sander, some of which are detail sanders and some of which are not. All detail sanders are orbital sanders although not all orbital sanders are detail sanders. Compare/contrast to other forms of power sander. Examples:

dewaxed shellac --- Shellac that has had removed from it the natural small amount of wax that the lac bugs produce. This is not necessary if shellac is to be the only finishing agent used on a surface, but if it is to be used as an undercoat or a barrier coat then it has to be dewaxed because other finishing agents (particularly polyurethane) do not adhere well to natural shellac. For oily woods, particularly cocobolo, polyurethane adheres VERY poorly and takes approximately forever to dry but a barrier coat of dewaxed shellac will bond like glue even to oily cocobolo (although it's not a bad idea to rub it down with acetone before the first coat) and then polyurethane will adhere strongly to the shellac and dry quickly.

dew point --- [also dewpoint] the temperature at which the water vapor in the air becomes saturated and the vapor begins to condense out into liquid form on surfaces. This is a more complex concept than that simple definition makes it sound like, and it is tied to relative humidity, but I'm not going to attempt the full discussion here. Suffice it to say that woodworkers want the dew point to be well below the ambient temperature (which is pretty much like saying we want low relative humidity) because that way our wood items are less likely to absorb moisture from the air and have problems with movement in service.

diagonal --- At an angle less than 90 degrees.

diagonal bracing --- Angled blocking installed between floor joists or rafters to stiffen them and distribute loads. Also called "cross bridging" and just "bridging". The installation of diagonal bracing is somewhat counter intuitive; First the upper edge is nailed in place with the lower edge just left hanging, then the sheathing, whether floor or ceiling, is put in place and nailed down, THEN the bottom edge of the diagonal bracing is nailed in place. If both the top and bottom of the bracing is nailed before the sheathing is laid down, there is a risk that the joists will become mis-aligned vertically due to pressure from the bracing and they will then not provide a flat surface for the sheathing.

diagonal cutters --- a type of pliers designed to cut wire. While the nomal version has jaw edges that meet in a symmetrical V shape where the cutting takes place, there is a version, called "flush-sided" or "flush-cut" that has the shape more like a V with one side straight up so that the cross section has one side of the cutting joint as a straight line because that version is specifically designed for snipping off the protrusions on the underside of printed circuit boards after components are soldered into the board. This type is often called "wire snips". Although these originated as electrical pliers, most woodworkers will have a pair around. Examples:

diagonal grained --- Wood in which the annual growth rings are at an angle with the axis of a piece as a result of sawing at an angle. That is, rather than running parallel to the long edge of a plank, for example, the grain runs at an angle to it. This is a form of cross-grain and is not a flaw in the wood, it is just a comment on the way the wood was cut, but such wood is not permitted for structural applications in the American Forestry Association guidelines because it does not have the same structural strength as an equal-sized piece of the same species that has the grain running parallel to the long edge.

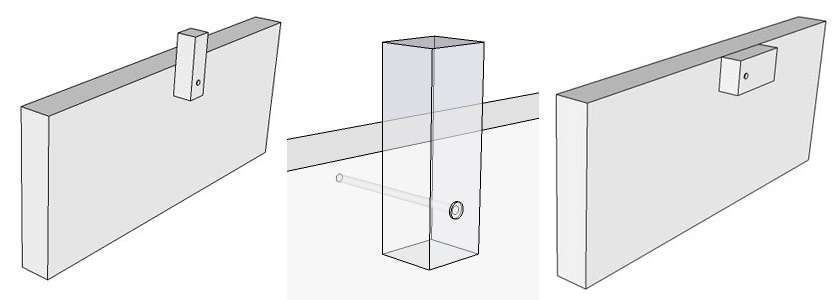

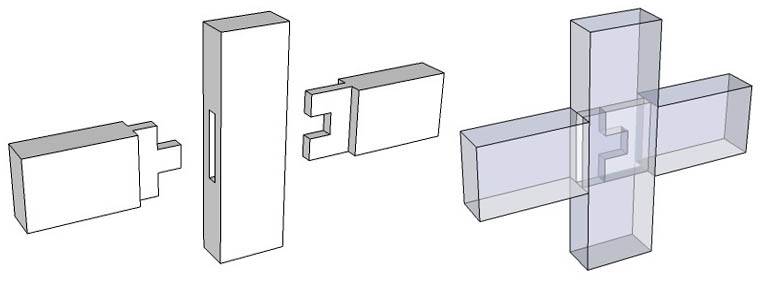

diagonally wedged mortise and tenon --- A mortise and tenon joint in which the tenon has a wedge that runs diagonally from one corner to the other, thus providing pressure in both directions at once. Personally, I do not see any structural advantage to this joint that would justify the extra complexity of construction, so I have to believe that when it is done, it is done for cosmetic rather than structural reasons. Example:

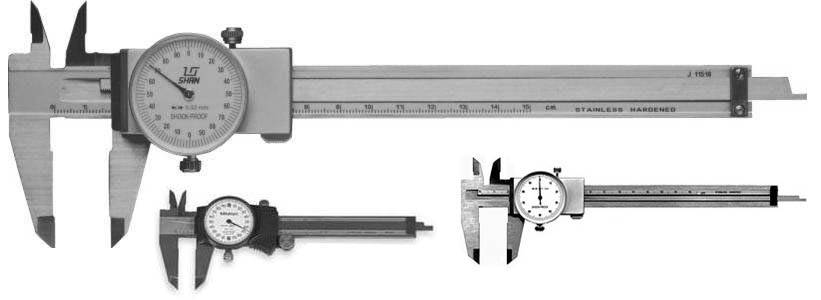

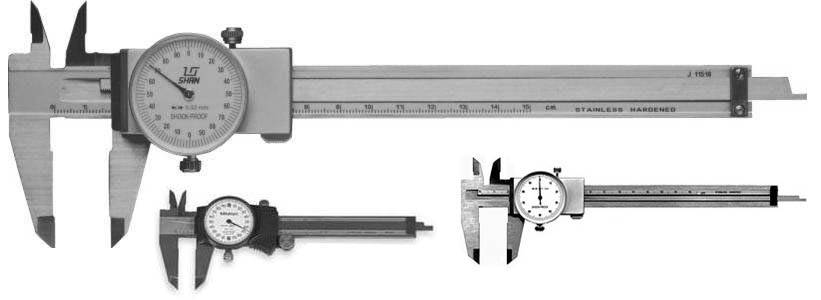

dial calipers --- This form of calipers could well be called "vernier plus" calipers because they are a pair of vernier calipers with a dial that gives fine-increment reading of the lowest scale section of the vernier scale, thus making the dial calipers more accurate than the vernier calipers. The dial has traditionally been a mechanical rotary dial (think of a stop-watch) but in recent years with the advent of LCD readouts, a new form of digital calipers has come on the market. Examples:

dial gauge --- A sensitive measuring instrument with a circular graduated face and a pin which activates a rotating pointer on the face to measure variation in pin movement in thousands of an inch. Used to measure runout among other things. Examples:

diameter at breast height --- The standard measurement of a tree's diameter is usually taken at about 4 1/2 feet above the ground, nominally breast height. Thus, when it is said that a tree has a diameter of 3 feet, the implication is that that refers to the diameter about 4.5 feet off the ground, not right next to the ground and not 20 feet up the trunk. If a tree has buttresses then the diameter is always taken above the buttresses.

diamond --- (1) An extremely hard glass-like material made from carbon under high pressure in the bowels of the earth and spit up by volcanic action. These days it is also produced synthetically. In woodworking, the material is used to create diamond sharpening stones which are used both to sharpen tool edges and also to flatten other less hard sharpening stones.

diamond --- (2) A shape like a parallelogram but stood up on one corner.

diamond matching --- A form of veneer matching where four sheets of veneer with a fairly straight grain pattern are arranged so that the grains of the sheets, taken together, form a diamond pattern (also can be seen as a parallelogram tipped up onto one corner). Because diamond matching is, in practical terms, a pair of book matches, it suffers from the same loose side / tight side matching problem that is described with book matching. When the sheets in diamond match are turned ninety degrees so that they all point away from the center of the four sheets, the result is technically called reverse diamond matching. Compare/contrast to other forms of veneer matching. Examples:

diamond parting tool --- A lathe tool; This is a variation on the standard parting tool in which the sides of the tool are expanded outward so that it has a diamond-shaped cross section which gives the tool extra rigidity. The shape also makes the tool usable in face turning moving directly in towards the headstock, which could not be done without the clearance this shape provides at the top and bottom of the shank. Examples:

diamond point chisel --- synonymous with spear point chisel

diamond point scraper --- synonymous with spear point chisel

diamond sharpening stone --- synonymous with diamond stone

diamond side cutting scraper --- see side cutting scraper

diamond stone --- A type of sharpening stone that uses an artificial diamond grit bonded to a metal plate for the sharpening. The plates usually dotted with holes that hold the diamond grit and the rest of the area gives the swarf a place to go so it doesn't build up to interfere with the sharpening (see open coat. The plates are normally mounted on a resin or plastic base and thus have the same overall size and shape as a more traditional rectangular stone. Diamond stones do not require the use of a lubricant. Unlike other stones, which can become rounded with use, thus decreasing their effectiveness, diamond plates remain flat, which makes them an ideal tool to use in re-flattening other sharpening stones as well as being sharpening stones in their own right.

diaphragm --- Sheeting/paneling that is attached (glued, nailed, screwed, whatever) to framing to provide extra shear strength to resist wind and earthquake loads. Most often made of plywood. See also plywood diaphragm.

dibber --- an alternate name for a dibble

dibble --- a wooden hand tool with a pointed end, used to make holes in the ground for planting seeds or bulbs. Some commercial ones come with a T-handle, some in "L" shape, and some come with steel tips. Some commercial ones are totally steel or plastic. Woodworkers commonly turn the simple straight wood version of these as a starting projects when they first get their lathes. In practical terms, you could just take an old broken broom handle and turn down the end on a belt sander, but hey that would just be practical and not very aesthetically pleasing. Examples:

die --- see tap and die

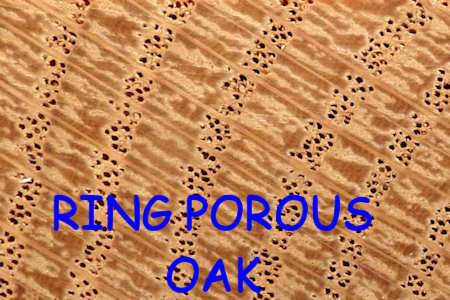

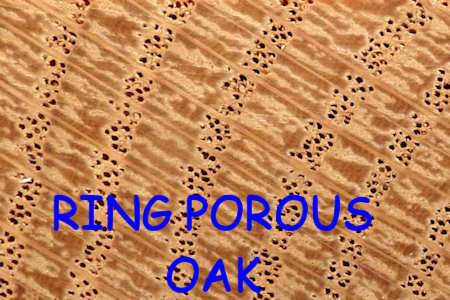

diffuse porous --- A group of hardwoods in which the pores tend to be uniform in size and distribution throughout each annual growth ring or to decrease in size slightly and gradually toward the outer border of the growth ring. Below on the left is a pic of birch, which is diffuse porous, and on the right a pic of red oak, which is ring porous.

digital calipers --- This form of calipers is just a pair of dial calipers with a digital readout in place of the normal rotary mechanical dial. Examples:

dimensional stability --- The ability to maintain the original intended dimensions when influenced by a foreign substance. Wood is hygroscopic, and is not dimensionally stable with changes in moisture content. Some species of wood are much more dimensionally stable than others. In addition, composite materials are substantially more stable than their solid counterparts. See movement in service.

dimension lumber --- lumber that is cut to standard commercial sizes for use in the construction industry. This is almost exclusively made from softwoods. By using standard sizes, the lumber yards and construction companies make dimension lumber a standardized commodity item with all the accompanying efficiencies. Dimension lumber is sold in nominal sizes as shown in the table given with that term.

dimension parts --- Apparently this is an older term, largely superseded by the term hardwood dimension lumber.

dimple figure --- synonymous with pomelle

dip --- An application technique for putting finishing agents on a wood surface. Dipping is used mostly for small objects, such as small toys, and is an obviously imprecise method that would not be suitable in situations where good control is needed on the amount of finishing agent applied since it causes localized flooding (pooling in crevices for example).

direct current --- [DC] The kind of power produced by a battery. So called because the electrical current always flows in one direction. Compare/contrast to alternating current.

discoloration --- An unexpected and (generally) undesirable change in color of wood. There are many common causes including all of the types of stains listed with that term plus stains due to chemical action of vat treatments, and those caused by unexpected reactions of finishing agents and/or adhesives.

dish --- See lathe turnings.

disk sander (benchtop model) --- A large power sander that uses a disk of sandpaper. The benchtop model is basically identical to the floor model disk sander but without the stand. Compare/contrast to other models of power sander. Examples:

disk sander (floor model) --- A large power sander that uses a disk of sandpaper and has a stand that brings it up to a comfortable working height. There is also a bench model disk sander that is essentially identical to the floor model but with out the stand. Compare/contrast to other models of power sander. Examples:

dissolve --- To cause to change, in a liquid called the solvent, from a solid to matter that becomes part of the liquid. The matter that dissolves is called the solute Matter that is just floating around in a liquid but which is not dissolved, is said to be in suspension. As an example, sugar will dissolve in water, but minerals from the soil will often just go into suspension.

distilled water --- Water which has been purified by vaporizing the liquid, collecting the vapor, and then condensing it back to a liquid. This process removes any contaminants such as dissolved minerals.

distortion --- A general English language term meaning a change in the shape of something. As regards woodworking, distortion is usually described by more specific terms such as warp, crook, cup, bow, and twist,

distressed --- A term describing something that has been subjected to distressing

distressing --- (1) The process of intentionally scratching, gouging, denting and otherwise messing up the finish and/or surfaces, particularly the top horizontal surface, of a piece of furniture to give it an aged look.

distressing --- (2) How it feels when one's spouse says "You've been spending too much money on wood!". This gives woodworkers an aged look.

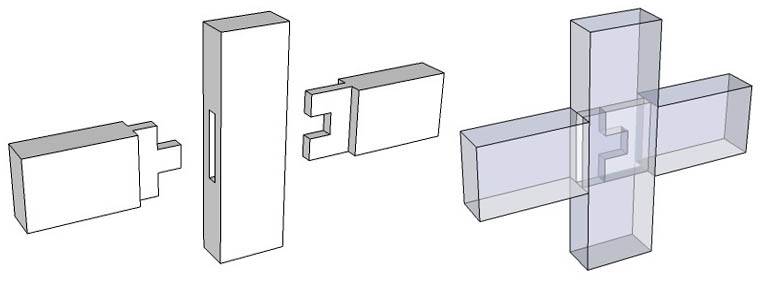

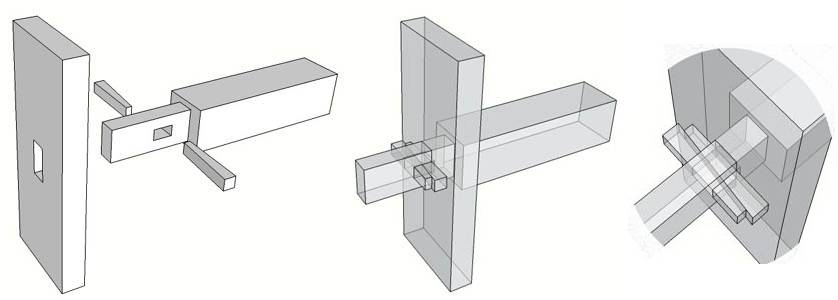

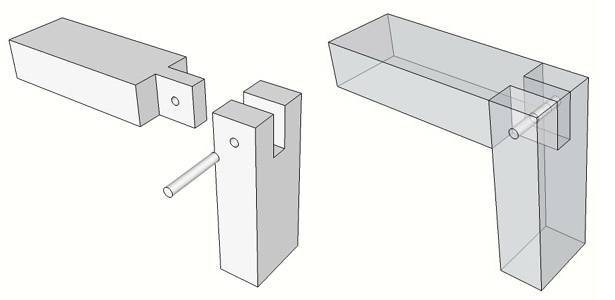

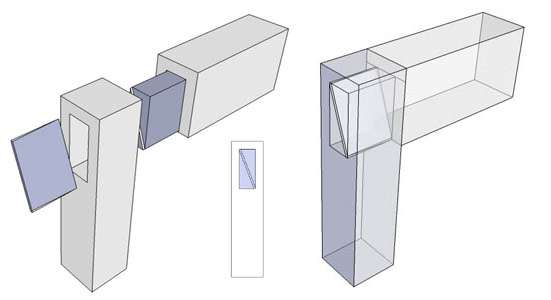

divided mortise and tenon --- A mortise and tenon joint technique for use when the tenons from two rails both have to go into the same mortise. Rather than just butt them against each other in the middle, the joint is given extra strength and extra glue surface by notching one and putting a projection (sort of a tenon on the tenon) on the other. Example:

dividers --- Also called a "measuring compass" (to distinguish it from the kind of compass that tells you which way is north), this is a measuring device consisting of a pair of legs both joined to a pivot at one end and each sharpened at the other end. Used to transfer measurements from one place (such as a ruler) to another (such as a map or a work surface). If a pencil is put in place of one of the legs, the construction is called a "drafting compass" but commonly called just a compass. Examples:

dividing head --- synonymous with index plate

DIY --- Do It Yyourself. Describes homeowner / hobbyist activities, tools, and work areas, as opposed to those of professionals, even through the two are sometimes similar or even identical.

dock washer --- A very large, thick fender washer for use on heavy construction (such as a marine dock, thus the name).

dog leg --- [also dogleg] A term used to describe any bend that is at least somewhat similar to the shape of the bend in a dog's leg. The word "cranked" is also used to mean dogleg. In woodworking it is used when referring to the shape of some tools and furniture legs. Beyond tools it is used in referring to a huge number of items including golf courses. See, for example, cabriole leg, cranked chisel, and cranked hinge. Examples of the shape:

dog leg chisel --- synonymous with cranked chisel

domestic --- Of local origin; compare/contrast to exotic. Technically, any wood that is grown in the USA is a domestic wood in the USA, but sometimes rare or heavily figured woods (e.g. desert ironwood, which is both) are listed with the exotics in vendors catalogs.

dominant trees --- Trees that extend above surrounding trees with a crown that captures sunlight from above and around the canopy.

domino joiner --- see Festool Domino joiner

donut chuck --- A homemade jig for finishing the bottom outside of bowls after all of the upper part, inside and outside, has been turned on a lathe. It consists of two sheets of plywood (other material could be used but plywood is highly recommended for these jigs), one solid to attach to the faceplate and the other with a hole in it for the bowl, and 3 or 4 bolts holding the two sheets together and parallel to each other in a way that captures the bowl, centered properly so that the bottom can be turned. That is, the face of the bowl goes flush against the faceplate piece of plywood and the other piece comes down over the bottom of the bowl, leaving enough bottom exposed to be turned, and the bolts then keep the bowl locked in place for turning. There are versions (see left-most example in the composit pic below) which are designed such that the "bottom" piece of plywood sits behind the faceplate. Examples:

door hinge --- A butt hinge that is strong enough to hold a house door. Often, door hinges will be somewhat fancy instead of just plain flat metal, and they will also frequently have a finial at both the top and bottom of the hinge pin. Door hinges are often put into mortises in both the edge of the door and the frame, as can be seen in the lower right portion of the composite pic below. Door hinges on external doors are most often made of either brass or stainless steel to avoid corrosion due to exposure to moisture. Eamples:

door leaf --- The hinge leaf that is mounted to a door. Compare/contrast to frame leaf.

door saddle --- a piece of wood (or it could be marble or other material) that is placed beneath the bottom edge of a door (usually an exterior door) to cover the joint between inside and outside flooring material and also to provide a weather seal. Although a door saddle can be flat, it is more often the shape shown in all of the examples in the composite pic directly below. Examples:

door sill --- see sill

door wing --- synonymous with door leaf

dormer --- An area of a building that protrudes from the plane of a sloping roof surface. Usually it is a room extension built to accommodate a vertical window. It is called a gable dormer if it has its own gable or a shed dormer if it has a shed roof. It is most often found in upstairs bedrooms where it provides extra space and light.Examples:

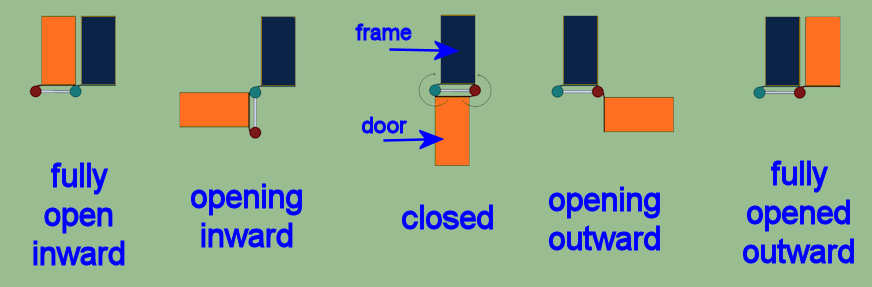

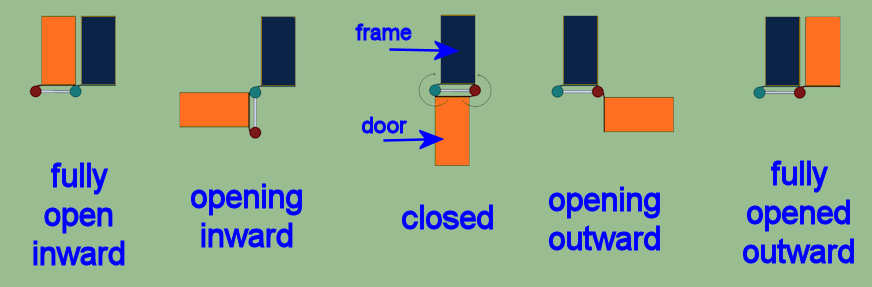

double action spring hinge --- A type of hinge that has two (hinge) barrels that act in a way that allows a door to swing more than 180 degrees in each direction (in and out) and spring-loaded so that the door always return to center closed position. Also called "double barrel" hinge, "saloon door" hinge, and "cafe door" hinge. In addition to the composite pic below of examples of this type hinge, I have, to show the action, created a graphic that shows the operation looking down onto a door and frame, with directions arbitrarily designated as "inward" to the left and "outward" to the right (and only showing a short portion of the door and frame). Note that the door swings outward centered on the barrel colored dark red and it swings inward centered on the barrel colored blue and the two barrels are attached by a 3rd (middle) leaf. Examples:

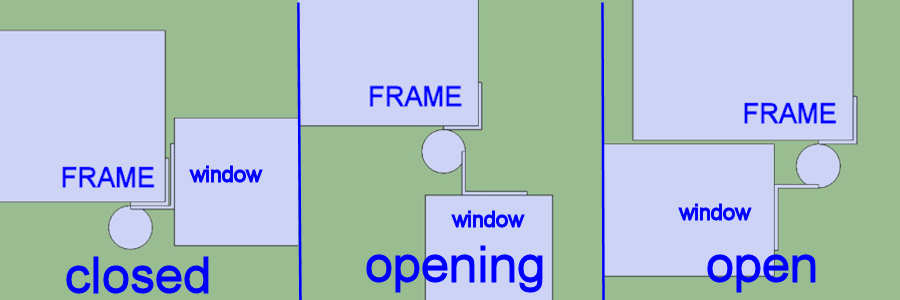

double bottom cooperage --- synonymous with tight cooperage

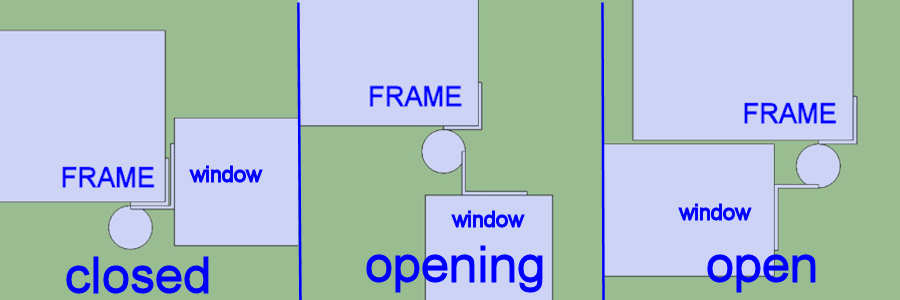

double cranked hinge --- A type of hinge that has a crank on both leaves and thus allows a door or window to swing through 180 degrees and move completely clear of the door frame area. A similar item with only one of the two leaves having a crank is called the single cranked hinge. Cranked hinges are also called "stormproof hinges" because of their common use with the kind of louvered panels that used to be called "storm windows" before modern technology made that term come to more commonly mean something else. See hinge parts for a discussion of the parts that make up the hinge. Note that in the graphic below, I have drawn the window such that when closed it sits proud of the frame, but it could just as well be mounted so that it ends up flush when closed (which would result in their being a larger gap at the hinge when it's fully open, but that's not a problem, it just didn't look as neat when drawn that way). Examples:

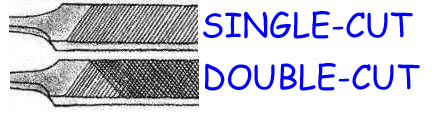

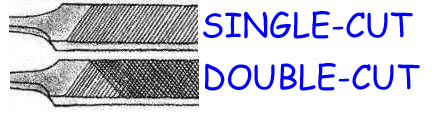

double cut --- A designation regarding files that indicates that the cutting ridges are arranged as two crossed sets of parallel rows, as opposed to single cut in which there is just one set of rows. Example:

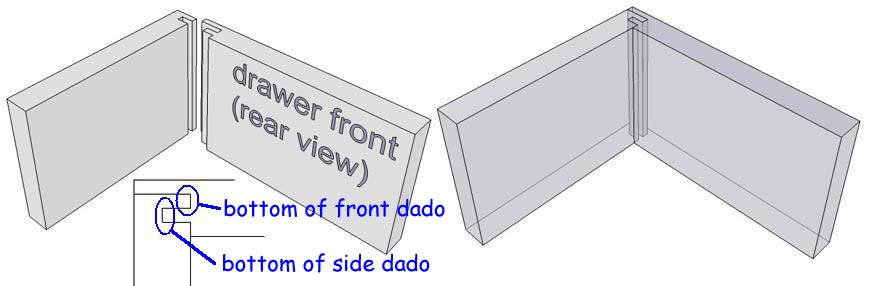

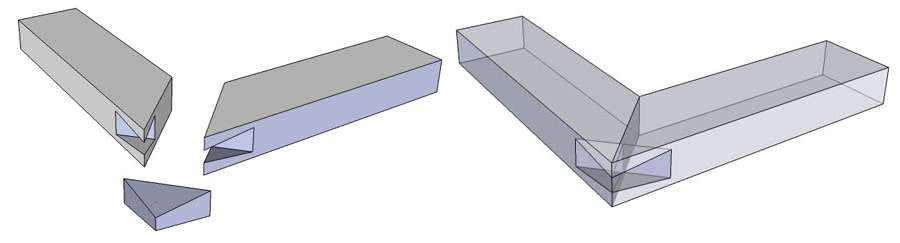

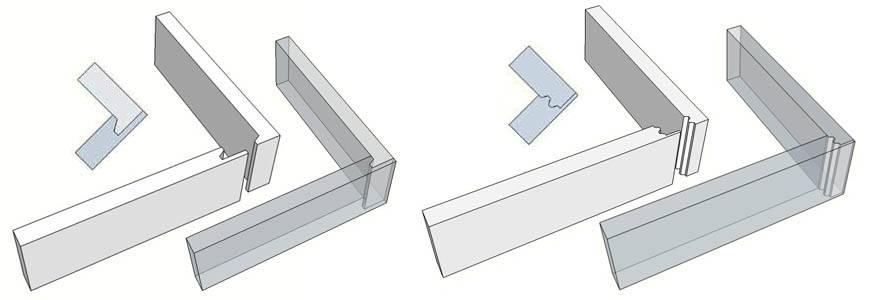

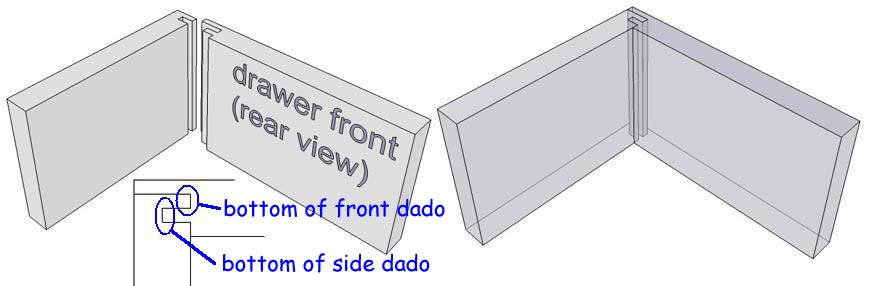

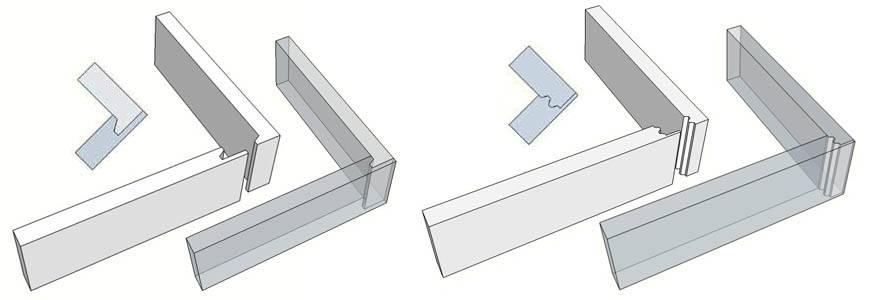

double dado --- A joint that is very similar to the drawer locking joint and which in fact is often used for that purpose. It is a slightly more complicated version of the locking rabbet. In joining the ends of two planks, a dodo is cut in each; best explained by an example, so here you go:

double demountable hinge --- This is a somewhat complex type of specialty hinge that is designed to facilitate installation and adjustment of cabinet doors, especially kitchen cabinet doors where there are typically many in a row and you need them to all line up neatly. The mechanism that allows the easy adjustment that is at the heart of this type of hinge is a tab that is inserted into a mortise in the wood and that is cut by a demountable hinge slot cutter router bit. The tab is pulled into the inside of the wooden section (door or frame) by clamping pressure exerted by a countersunk machine screw that goes through the (hinge) leaf and into a threaded hole in the middle of the tab but which does not touch the wood anywhere because the slot is cut extra large to allow for movement (up and down AND back and forth) of the screw so as to align the door as needed. Because this tab mechanism is on both the door leaf and the frame leaf, there is a great deal of flexibility in terms of adjusting the position of the door. Compare this to the great precision that you have to have in placing the screw holes for mounting other types of hinges to make sure all the cabinet doors line up and you can see why this type of hinge is a favorite of kitchen cabinet installers. There is another version of this type hinge that only has the tab mechanism on the door leaf and it is called a single demountable hinge. This is a partially concealed hinge because only the barrel and part of the frame leaf are exposed, and it is a type of flush hinge. You can't see that in the pics below because the angle is wrong on all of them, but if you look at the illustrations with single demountable hinge you'll see what I mean. The flush aspect is implicit in the mounting pic in the upper right hand corner, but you may have to think about it a bit to see it. Although it's not obvious from the pics below, some styles of this hinge require a mounting technique that is slightly different from that shown in the upper right below. The second from the left hinge in the pic below exemplifies this; if you look carefully, you'll see that the only way this hinge could be mounted is if the entire back edge of the door be given an edge rabbet. The term "demountable" in the name is somewhat misleading since it would normally imply that no screwdriver is required to demount the hinge (see lift off hinge), but that is not the case with this hinge, although it IS easier to remove than traditional hinges because only the one machine screw in the frame leaf needs to be removed to dismount the door AND the hinge. Examples:

double dovetail half lap --- synonymous with corner half lap with double dovetail

double ended calipers --- Balloon calipers that have a mirrored version on each end. One end does the measuring but is partially hidden when used, for example, to measure the thickness of a hollow form, thus necessitating the mirrored end to actually see that the thickness is that is being measured by the partially hidden end. Examples:

double hung sash window --- synonymous with sash window, but the term emphasizes the fact that both sashes have sash weights.

double insulated --- Portable power tools tend to have steel frames on the inside, so if there is a short of an otherwise insulated electrical power wire to the frame, you could get electrocuted (which most of us would consider to be a bad thing); Better tools have a non-conductive plastic casing that provides a second layer of insulation to protect the user from electric shock and are thus said to be double insulated. Stationary floor model tools such as a table saw don't have plastic shells, but do have extra insulation inside for safety.

double rabbet joint --- A joint where two edges are both rabbeted and then the two are joined. With no other support this is a very weak joint, only slightly better than an unsupported butt joint. Example:

double shouldered sliding dovetail --- synonymous with sliding dovetail; the only reason for using this particular term would be to specifically distinguish the joint from a single shouldered sliding dovetail

double wedged mortise and tenon --- Although you would, logically, think that this term would refer to a construct exactly like the single wedged mortise and tenon joint but with two wedges instead of one, it actually is used to refer to a tusked mortise and tenon with two wedges instead of one. Note that with two wedges, the outer surface of the wedge cutout is NOT angled as it is in the normal tusked mortise and tenon, but the inner surface is recessed so the wedges exert a pulling force on the piece that accepts them. This joint normally does not use glue; it is a knockdown joint. Example:

dovetail --- (1)[noun] see tail

dovetail --- (2)[noun] see dovetail joint

dovetail --- (3)[verb] To tightly merge two pieces of something together (literally, it means two pieces of wood cut and fitted in a dovetail pattern, but the word has taken on a broader use).

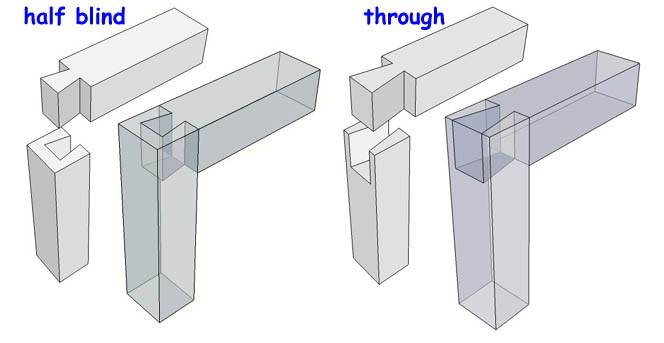

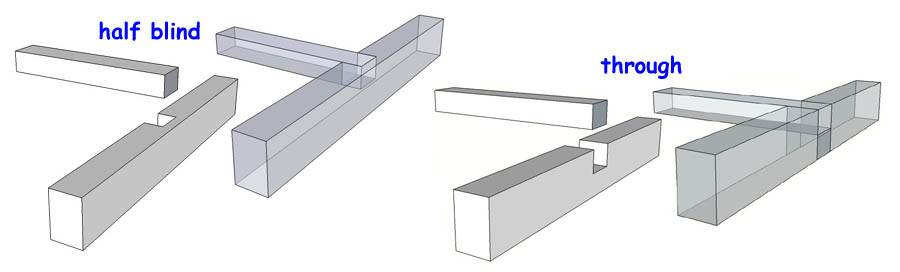

dovetail bridle joint --- A bridle joint with a dovetail prong replacing the more standard rectangular prong. As with the standard bridle joint, and as shown in the examples below, the joint can be half blind or through. Examples:

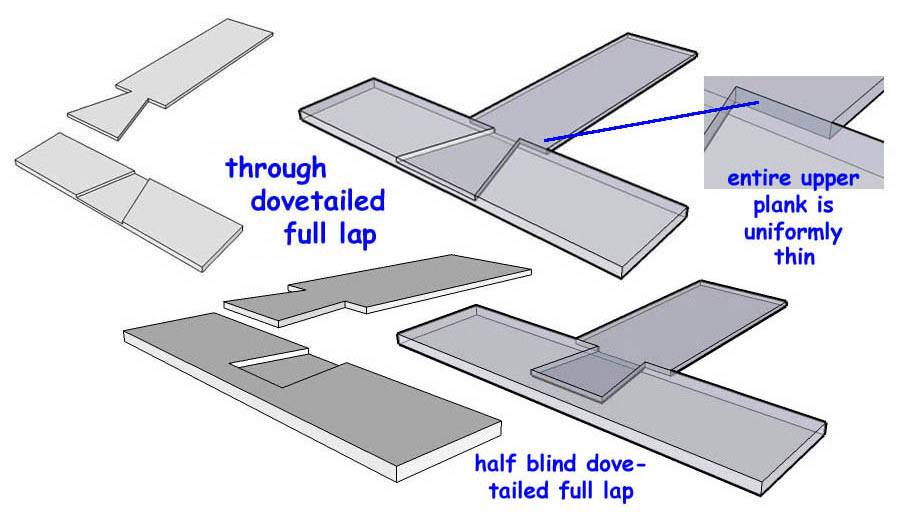

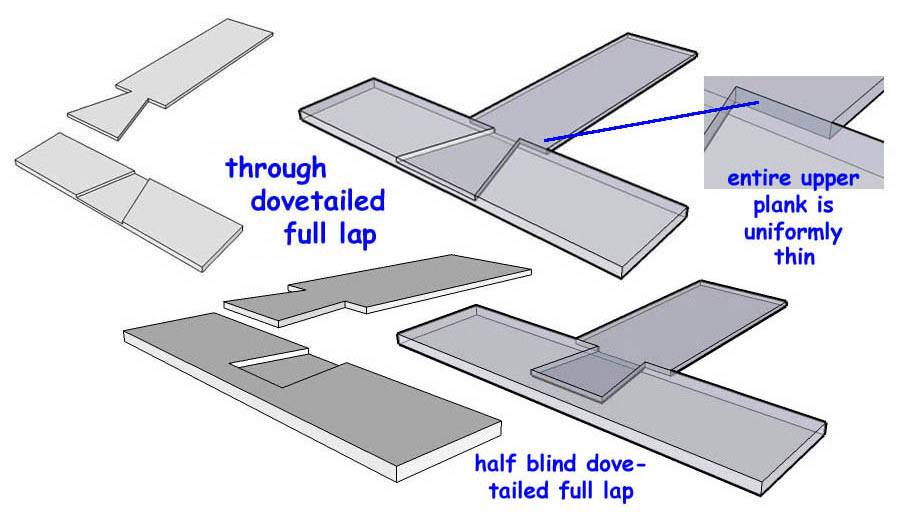

dovetailed full lap --- A full lap joint where the cross piece has a cutout for a dovetail and the mating piece has its end shaped in a single dovetail. As shown in the examples below, the joint can be through or half blind. Compare/contrast to keyed dovetail full lap. Examples:

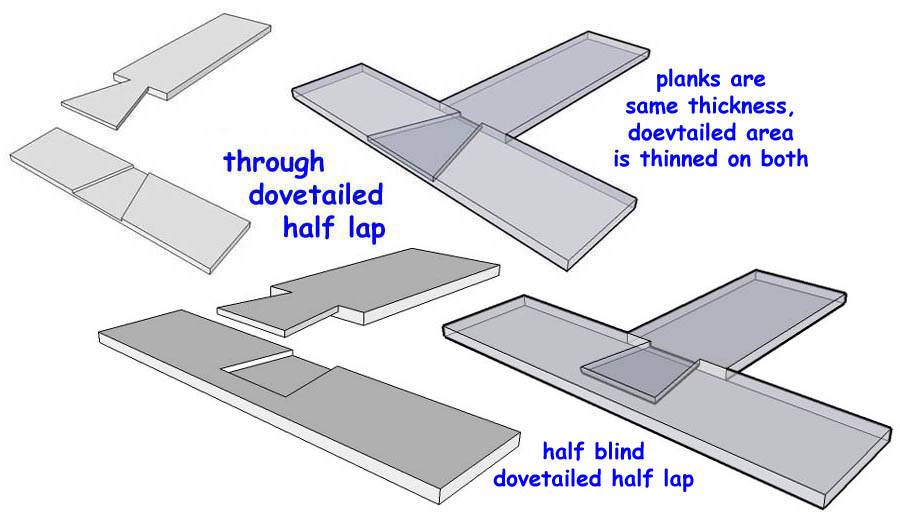

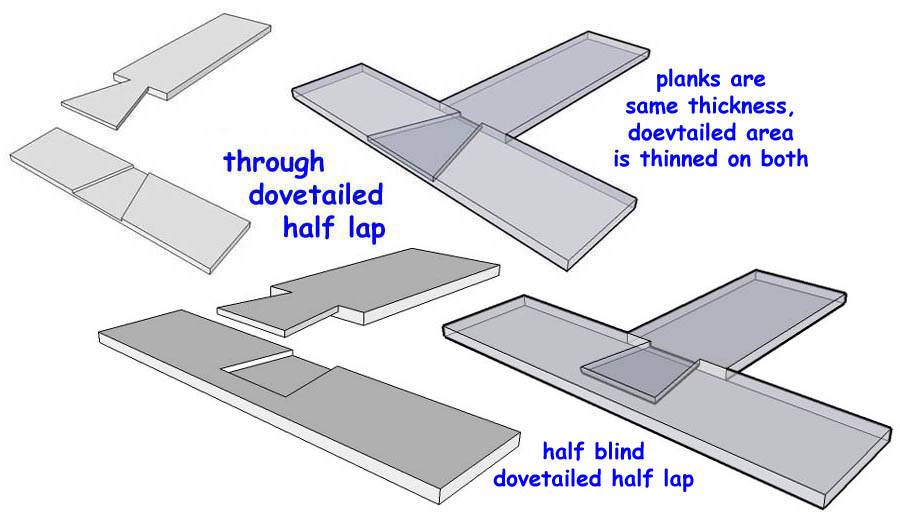

dovetailed half lap --- A half lap joint where the cross piece has a cutout for a dovetail and the mating piece has its end shaped in a single dovetail. As shown in the examples below, the joint can be through or half blind. Compare/contrast to keyed dovetail half lap. Examples:

dovetail jig --- Although dovetail joints are a rite of passage for cabinet makers, they are very time consuming when done by hand, so commercial jigs have long been available to ease the effort. These are generally highly adjustable and are used with dovetail router bits. Examples:

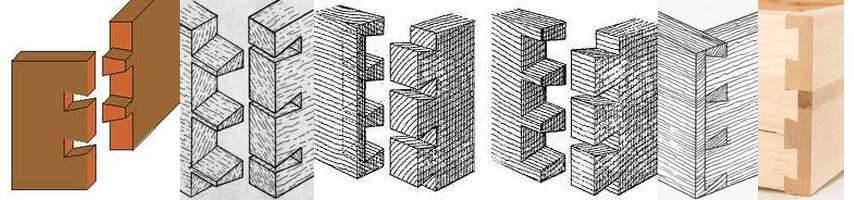

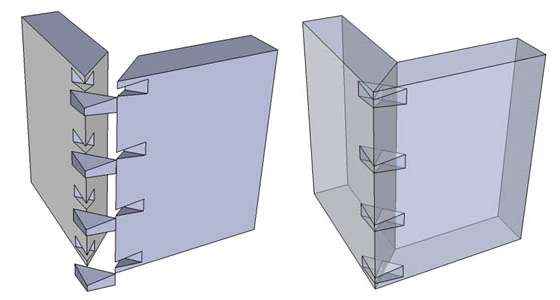

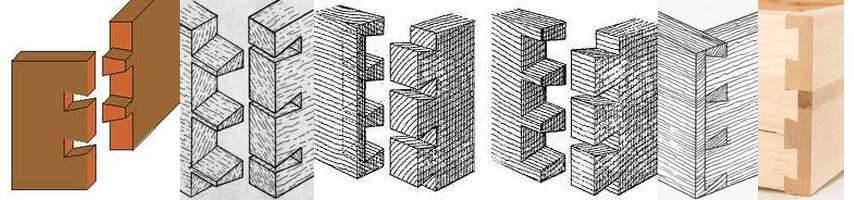

dovetail joint --- A joint formed by creating a dovetail shaped tenon and a corresponding mortise. The size, shape, and angles of dovetail joints are infinite in their variety. They are exceptionally strong and resist separation much better than most joints. They also provide a visual demonstration of woodworking expertise and elegant joinery and are sometimes used for that reason alone. If the cuts show on both of the mating surfaces, that is called a through dovetail joint and if they only show on one surface, that is a half blind dovetail joint and if they are totally hidden from view, that is a blind dovetail. Because the true blind dovetail is a very difficult joint to make and because it is not often used, common usage frequently has the term "blind" dovetail used for what is technically the "half blind" dovetail. More illustrations are given with each term, but here are examples of the three main types of dovetail and a long list of various dovetail joints is given with the term dovetail router bit. See also dovetail jig.

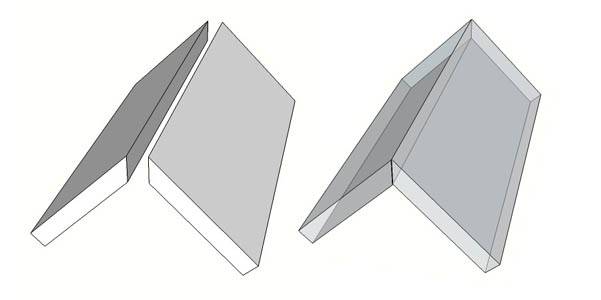

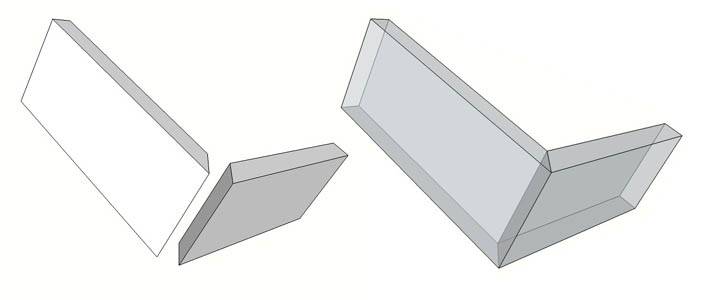

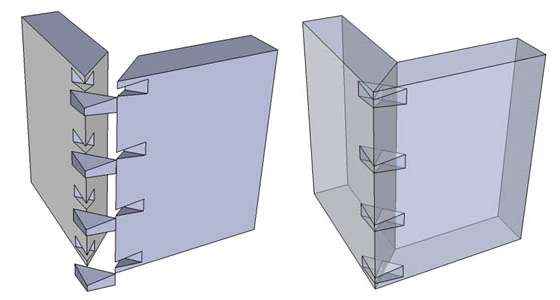

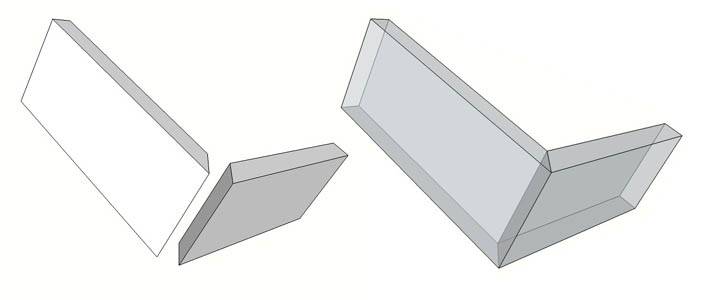

dovetail keyed mitered edge joint --- An edge miter joint that has been strengthened with a key in the shape of a dovetail. This joint is normally made by first making the miter cuts and then holding the two pieces together in a 45-degree jig and passing it over a dovetail router bit to make the mortise and then making a sliding dovetail stick to put in the mortise as the key, which is then cut off flush after the glue dries. In the drawing below, the key is shown in its final size, but in real world construction, it would be cut overlong, slipped in and glued, and then worked to be flush after the glue dried. Example:

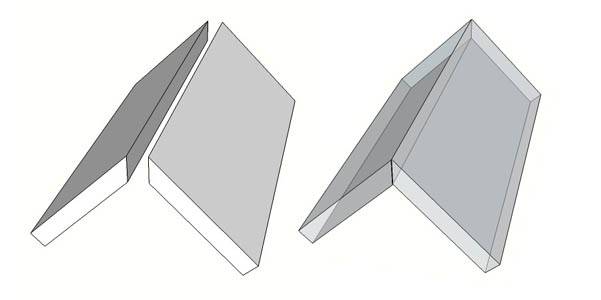

dovetail keyed mitered face joint --- A face miter joint that has been strengthened with a key in the shape of a dovetail. This joint is normally made by first making both miter cuts and then holding the two pieces together in a 45-degree jig and passing it over a dovetail router bit to make the mortise and then making a sliding dovetail stick to put in the mortise as the key, which is then cut off flush after the glue dries. In the drawing below, the key is shown in its final size, but in real world construction, it would be cut overlong, slipped in and glued, and then worked to be flush after the glue dried. Example:

dovetail keyed miter joint --- A face miter joint or an edge miter joint with a key in the shape of a dovetail (as opposed to a flat arrow key as is found in the keyed face miter joint and keyed edge miter joint). The two common types are the dovetail keyed mitered edge joint and the dovetail keyed mitered face joint.

dovetail router bit --- A router bit that is used to cut surfaces for various kinds of dovetail joints. Below the illustration is a list of some of the joints that such a bit can be used for. Examples:

some of the joints this bit can be used to create:

dovetail saw --- synonymous with back saw

dovetail scarf --- synonymous with lapped dovetail scarf

dovetail scraper --- A lathe tool; a form of sidecutting scraper that is used to make a dovetail cut in the back side (base) of a bowl so that it will fit snugly into a similarly shaped surface on an expansion chuck. Examples:

dowel --- A wooden cylinder with a diameter from 1/4" to about 1 1/2" and a length which is generally something like 4 to 6 times the diameter, although there are no specific rules on that. In fact I have not seen any rules at all really, and I have heard the term used for wooden cylinder that was 4 feet long and a foot in diameter, but I think my limited definition is good for general use. Hardware stores sell long dowel rods from which individual dowels can be cut, and craft stores sell pre-cut dowels in various sizes. Precut dowels also come with ridged sides for ease of glue flow around them and also often have tapered ends which greatly eases their entry into tight holes. Another variety of precut dowel pins has spiral grooves around the side. Dowels have numerous uses, most particularly as part of various joints. See also dowel joint, pinned joint and peggedjoint. Examples:

dowel center --- A short metal cylinder with a raised point in the center; the device is inserted into a matching-sized hole in a piece of wood and when another piece of wood is pushed up against that, a dent is made in the 2nd piece of wood showing where a hole needs to be drilled so as to exactly match the hole in the first piece of wood so that a dowel can be inserted into the two pieces as part of a joint. Examples:

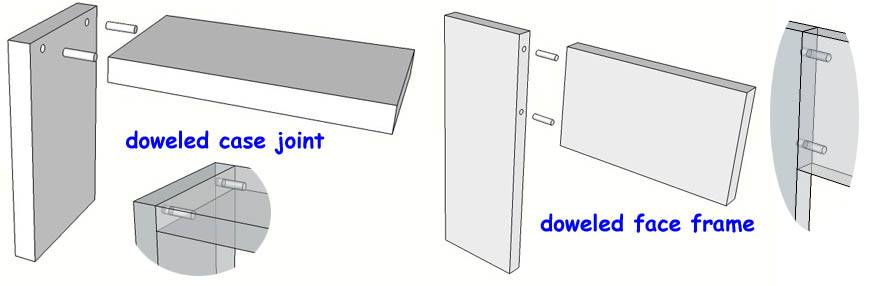

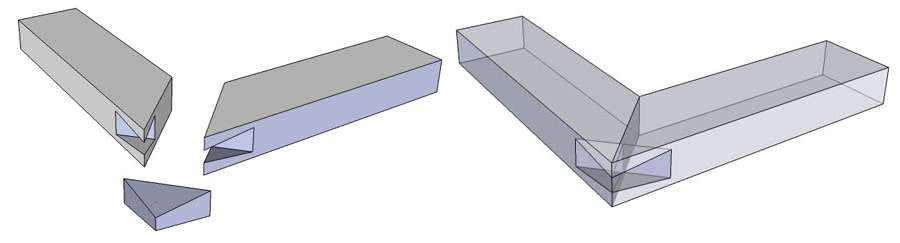

doweled mitered face frame --- A picture-frame type joint with a miter cut (usually at 45 degrees) where the planks meet at the corner and the joint is reinforced with dowels. This joint exemplifies the way that joints with lots of sub-characteristics can be named in different ways; this joint could just as well be called a "doweled face miter joint". Compare/contrast to splined face miter joint and (plain) face miter joint. Examples:

doweled through bridle joint --- A through bridle joint in which the tenon is pinned. Example:

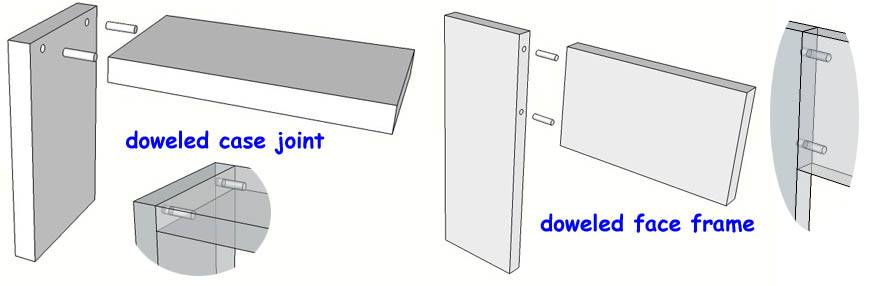

doweling --- using a dowel to strengthen a joint.

doweling jig --- a device that is clamped onto the edge of a plank so as to facilitate the accurate drilling of holes for dowels. Some have a clamp as part of the mechanism itself and some clamp onto a pair of planks so as to align opposing dowel holes for mating. Some have fixed size holes for a specific drill bit size and others have inserts that allow the use of various sized drill bits. Examples:

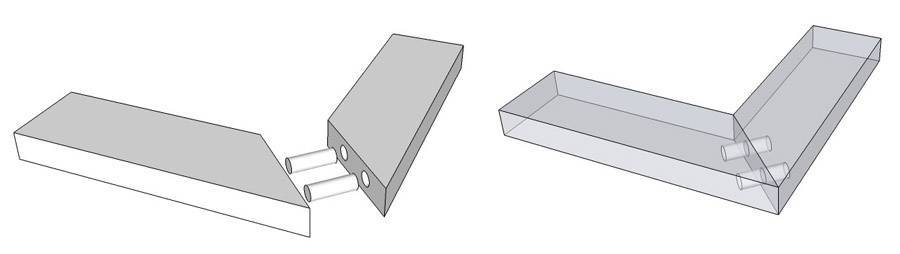

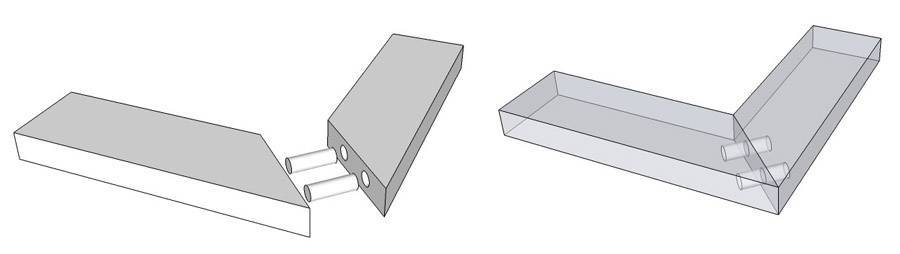

dowel joint --- Any joint where the pieces are joined by dowels running through the joint. This may be in addition to other techniques (such as dado cuts) used in the same joint. That is, "dowel joint" does not specify a particular TYPE of joint but rather the use of dowels to augment any type of joint. There are some definitions that disagree with what I just said and show a dowel joint as being specifically a butt joint with dowels. For those folks, here are a couple of butt joints with dowels:

dowel pin --- A small dowel segment used to strengthen a joint. See also dowel joint.

dowel rod --- A long wooden cylinder from which dowels are cut. Hardware stores typically sell dowel rods in 3-foot and/or 4-foot lengths with diameters from 1/4" up to 1 1/2". Examples:

dowel screw --- A cylindrical (not tapered) metal shank (typically of steel) with no head, wood screw threads, and both ends pointed. These are used to connect two wooden parts that have blind holes, such as the finial on a stair railing. Some are un-threaded in the center to make installation using a pair of locking pliers gripping the center easy. Do not confuse with a hanger bolt, which has a machine screw on one end and a wood screw on the other. Vendors sometimes list these two different items indiscriminately as one being the other. Examples:

downspout --- A tube that carries water from a gutter down to the ground.

doze --- A form of early decay characterized by a dull and lifeless appearance of the wood, accompanied by a loss of strength and softening of the wood.

dozuki --- A type of Japanese woodworking saw that is used for fine joinery work such as dovetails. Its Western equivalent is a back saw, although the Western back saw is cuts on the forward stroke whereas the dozuki cuts on the back stroke. Examples:

drawbore tenon --- A technique for providing a little extra tightness to a mortise and tenon joint. It is a pinned tenon but with a slight offset so that the insertion of the pin forces the tenon just slightly more in one or two directions that the opposite directions and helps assure that the joint does not loosen over time. When using this technique, the hole in the tenon has to be drilled when it is NOT in the mortise so that it can be offset by a little. Too much offset can make it hard or even impossible to insert the pin, so this technique requires some care.

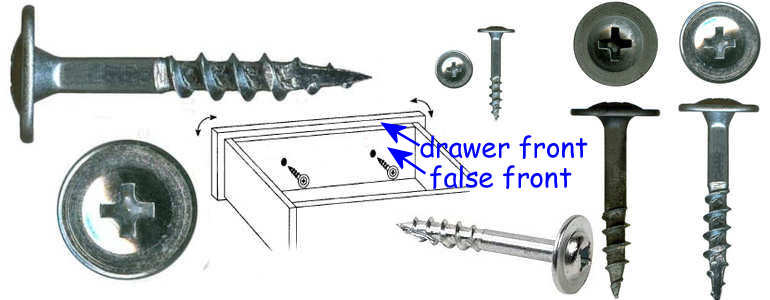

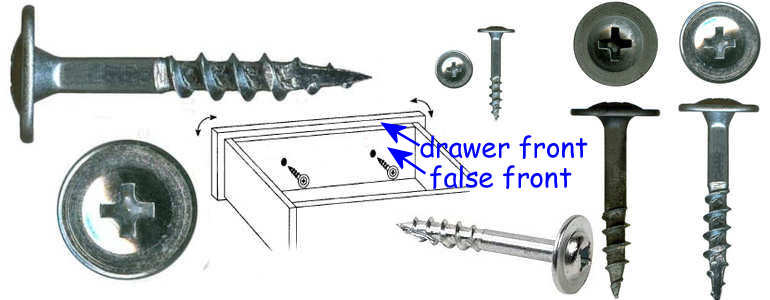

drawer front screw --- A screw, usually steel with a broad, flat head and an unthreaded area below the head then coarse, firm-griping threads below that. These are used in drawer fronts as follows and illustrated in the composite pic below: the false front is attached to the drawer sides and two oversized holes are drilled in it, then the drawer front, which is wide enough to hide the drawer sides and prevent the drawer from sliding back into the carcass, is attached to the false front through the oversized holes, using the drawer front screws. This allows some movement in drawer front so that it can be lined up precisely so as to not look skewed from the front of the cabinet, and then when it's lined up the screws are tightened. These are most commonly provided with Phillips head drive holes because a flat head drive could too easily slip off and mar the surface on the inside of the drawer. Examples:

drawer guides --- Hardware installed on drawer sides that supports the gliding/sliding motion of the drawer. This can be anything from a simple wooden strip up to roller-bearing guides.

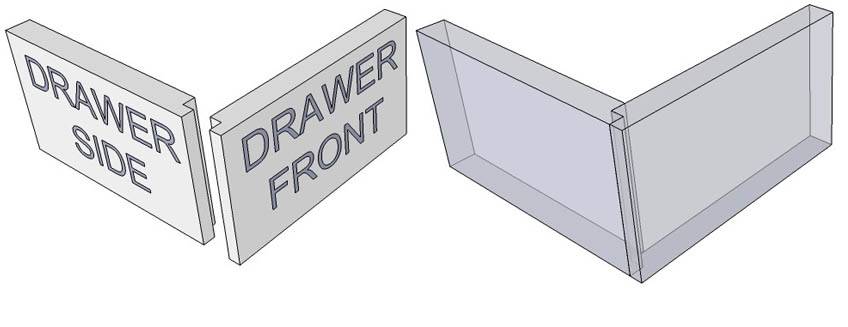

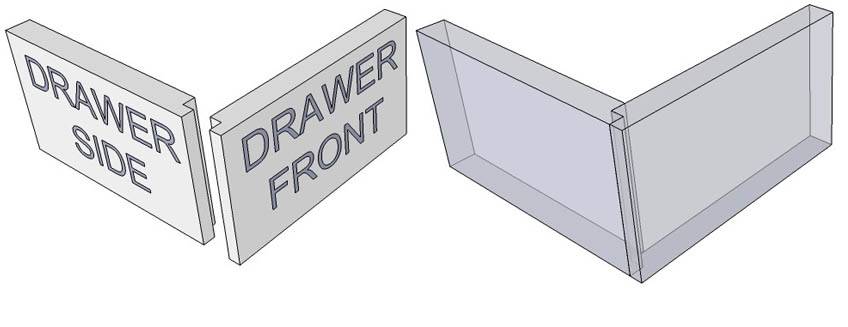

drawer locking joint --- There are numerous styles of joints, all pretty similar, that are called drawer locking joints, and several of them can be constructed with specialty router bits. What they all have in common is that they are used to join the side of a drawer to the front of the drawer and they do so in a way that provides both more glue surface and more mechanical strength than a common butt joint while still leaving the drawer face unblemished (in this regard, they can be considered to be half blind joints. See also double dado and locking rabbet Examples:

drawer stop --- A device that limits the travel of a drawer. The simplest such device is a short strip of wood that is nailed or screwed vertically into the the upper back of a drawer with part above the level of the drawer back and part below. To insert/remove the drawer, the stop can be swiveled down below the level of the drawer back. This term can also refer to a piece of wood at the back of a drawer that prevents the drawer from moving back beyond where the face of the drawer is flush with the face of the cabinet that it is housed in. Example:

drawknife --- (1) any knife-like tool that normally uses an inward (towards the body) stroke instead of an outward stroke. This includes spoke shaves and scorps. Most drawknives have a handle at each end of the blade but some scorps have a single handle. A common synonym is "drawshave" and a less-used synonym is "inshave".

drawknife --- (2) More specifically than definition (1) above, the term refers to tool with a wide but shallow blade with a handle on each end. It can be used to remove large slices or thin shaves. The blade may be straight or slightly curved. Such a tool is normally used on a workpiece that is gripped in something such as a shaving horse. Large drawknives can be used to dress logs; one use of a drawknife is to create a roughly cylindrical billet of wood for turning on a pole lathe. Examples:

drawshave --- synonymous with drawknife

Dremel tool --- A specific brand of high speed rotary tool that was the original such tool but which now has imitators. This is a fabulously useful tool and has an almost unlimited set of attachments of various sizes, shapes, and materials for use in operations as diverse as buffing, carving, cutting, drilling, grinding, sanding, sharpening, deburring, wire brushing, and just generally shaping and cleaning up most any kind of surface on any kind of material. See Dremel tool accessories for illustrations. Speeds range from a "slow" speed of 5,000 RPM to 35,000 RPM. I don't own any stock in the Dremel company, but I have to rave about their tool. For really small-area sanding and grinding, there just isn't anything else that will do what it does, and that's in addition to all of the many dozens of other things it does very well (on a small scale). It is available in both battery powered and a number of different AC-powered models. See also, Dremel tool accessories. Examples:

Dremel tool accessories --- These are some of the attachments you can get for the Dremel tool. I looked around for good pics to steal, as I have done for just about everything in this glossary, but couldn't find a decent set, so here are my own. As you can see, I have had these for a long time, use them quite a bit, and don't keep them clean. Two attachments that I don't show here are the little 3/4" circular saw blade which I seldom use, and the 3/4" grinding wheel that I go through so many of that I buy them in cylinders of 36 each in various thicknesses (thin, regular, and heavy duty). On my monitor, set for 1024x768, these are just about real size.

dress --- To smooth over and/or bring into a straight or flat condition. Although the standard terminology for a board that has been brought to flatness on two sides is "S2S" for "Surfaced on 2 Sides", it is also sometimes called "D2S" for "Dressed on 2 Sides". A tool piece, such as the toolrest in a wood lathe, that has become worn and ridged due to use but needs to be flat is said to be dressed when it is smoothed back to flatness with a file. A chisel edge which has become nicked and/or dull and which is brought back to the proper sharpness and bevel angle by a grinding wheel is said to have been dressed. A grinding wheel that has become worn may have to have its face brought back to a flat surface by the application of a grinding wheel dresser.

dressed --- see dress

dressed lumber --- Lumber that has been dressed by a smoothing process (such as by a planer or jointer) on at least one face or edge. The undressed surfaces may still be considered rough lumber. Compare/contrast to rough lumber.

dressed size --- This is the "actual size" discussed with the term nominal size. Also called the "actual size".

dressing --- see dress

drill --- (verb) the process of making holes in a material by use of a rotating bit

drill --- (noun) a tool for making round holes in wood or other material. See these related tools:

drill bit --- A cutting tool for use in a drill. The "common" or "normal" bit is the twist drill bit and that's what people normally think of when they say "drill bit", but there are numerous types, including:

drill chuck --- see chuck

drill press (bench model) --- This is just a smaller version of the floor model drill press. It always has a smaller height, usually a smaller throat), and usually a smaller quill travel. There are also bench models of the radial drill press. Examples:

drill press drum sander --- There are hard rubber cylinders made specifically to allow a drill press to be used as a drum sander. The cylinders compress slightly by turning a nut on the end and that tightens them against a sandpaper sleeve that is slipped over them and then a shank on the other end goes into the drill press chuck. The cylindrical holders and sandpaper sleeves come in many diameters and heights. There is another form of drum sander, the oscillating drum sander that takes the same sanding drums but there they mount with the shank downwards and the mechanism moves them up and down which overcomes a potential drawback of the drill press drum sander which is that slight imperfections in the drum will hit the workpiece at the same height on every rotation and can thus cause sanding scratches. Compare/contrast to other forms of power sander. Examples:

drill press (floor model) --- This is a stationary power tool for boring holes. It generally is about 6 feet tall and has an adjustable table that rides up and down on a cranked "rack and pinion" gear. The motor rides on the back of an upper assembly and the arbor housing is in the front of the assembly and there is a speed control mechanism, using belts, between the two. There is a handle on the side of the housing, usually with three spokes, that moves the quill up and down. The speed adjustment can be by way of internal belts that have to be changed manually or there can be a continuous variable-speed drive pully that allows the operator to change the speed by simply turning a lever on the front of the arbor housing. Two characteristics of drill presses that you'll want to consider when buying one are the throat depth and quill travel. There are also floor models of the radial drill press. Examples:

drill rod --- synonymous with threaded rod

drip edge --- synonymous with drip groove

drip groove --- A groove cut into the underside of a door or window sill to prevent rainwater running back into a building

drip torch --- A device that drips a flaming liquid mixture of diesel fuel and gasoline; firefighters use these torches to ignite fires in burnout operations.

drive center --- A lathe center that not only holds a spindle turning but also transfers the motor power through the headstock to the workpiece. There are two types and they are discussed individually in detail in this glossary. They are the spur drive and the Steb drive. Sometimes the term "drive center" is used to mean specifically the spur drive because before the invention of the Steb drive, the spur drive really was the only kind of drive center.

drop finial --- An "upside down" finial, used to adorn a dropped portion of a stairway newel (where the newel projects downward below the floor level of an upper floor). Example:

drop flap hinge --- A hinge designed for use with a vertical panel that covers the front of a cabinet section but drops down 90 degrees to provide a horizontal work space. Not to be confused with drop leaf hinge. These are specialty hinges, are round and have a "tongue" that slips out as the vertical portion is dropped down to become the work surface. Examples:

drop leaf --- An extension section on a table top that uses a hinged joint (most commonly in a rule joint) to allow the extension to be vertical at the side of the table (pointing towards the floor) when not in use but horizontal when in use. A drop leaf can be achieved by just face mounting a butt hinge on the bottom of table and the bottom of the butt jointed leaf, but a rule joint looks much nicer and is considered a more elegant look. Example:

drop leaf hinge --- For drop leaf table extensions and not to be confused with drop flap hinge. This is a butt hinge but with one of the hinge leaves wider than the other so as to clear the curved portion of the drop leaf. This is normally used with a special-shaped edge to the two fitting parts, as shown in the first composite pic below, but it can be a more simple, straight edge on each part as shown in the leftmost image in the second composite pic below. Examples:

dropped ceiling --- A "false" ceiling below the actual structural ceiling, usually made from a very light frame of aluminum strips that hold acoustic tiles. Such dropped ceilings often have cutouts for recessed lighting such as fluorescent light fixtures and they also provide space for heating/cooling ductwork and possibly water pipes and electrical wiring. The area above the dropped ceiling and below the structural ceiling is called the plenum.

drum sander --- A powered sander where the sandpaper is on a drum. Some versions use cut sheets of sandpaper on a slotted drum but most use prefabricated sanding sleeves that fit over a rubber housing, many of which are then expanded slightly to hold the paper sleeve in place during operation. Sizes range from tiny (on a Dremel tool to several feet in width for sanding wide planks, and styles are all over the map, including large floor model commercial models, shop built models, pneumatic-sleeve models (flexible drums), drill press models, hand-held models, and oscillating models that help avoid sanding lines. The major types, each with its own entry in this glossary, are listed below. Compare/contrast to other forms of power sander.

dry --- see sandpaper

dry cooperage --- synonymous with slack cooperage

dry fit --- Temporarily assembling the separate pieces of a woodworking project without adhesive or permanent fasteners but just putting them up next to each other (possibly with some use of clamps). This is done to check the accuracy and fit of joinery, get things lined up properly, and to determine the sequence for final assembly. When a dry fit is done, the craftsman normally uses witness marks to show how to mate the pieces back together after they have been taken apart.

drying --- The process of removing the moisture from green wood to improve its workability and to stabilize it so that it will not change size/shape after being put into service. Also called seasoning. Sometimes this is done by leaving wood open to the air for many months or even a few years, in which case it is called air drying. It can also be done more quickly in a kiln, in which case it is called kiln drying. The process can cause flaws in the wood and these are called drying defects.

drying defect --- An irregularity that develops in wood during the drying process and that will reduce one or more of the following wood characteristics: value, appearance, strength, durability, and/or general utility. Frequently, any given species will be susceptible to more than one drying defect. The most common drying defects include:

drying kiln --- see kiln

drying schedule --- A sequence of wood-drying conditions, generally done in a kiln and called a "kiln schedule", which result in a gradual decrease in moisture content of the wood with a good compromise between the desires to (a) minimize the degrade to the wood and (b) not take forever to get the drying done. Generally (a) mostly wins out because getting wood dried quickly is pointless if you induce flaws in the wood. Some drying schedules call for a period of pre-drying in open air before kiln drying starts. Kiln drying is, as I understand it, as much art as science --- you don't just hire the next guy off the street and make him a kiln operator. Also called "kiln schedule".

drying time --- (1) The interval between the application of a coating and when it is ready either for the object to be put in service or for another coat.

drying time --- (2) The amount of time for which wood has been left to dry, either by air drying or kiln drying.

dry joint --- A joint that does not use any adhesive but rather is either a pressure fit or uses nails or screws. Sometimes the term is used to mean a knockdown joint, which of course doesn't use glue OR fasteners. The term is also applied a joint that WILL use glue and/or fasteners but which is at the moment just being fitted to make sure the wood edges meet accurately.

dry lumber --- lumber that has had its moisture content reduced by way of air drying or kiln drying to the point where it can be worked and put into service. The ASLS says that for softwood lumber, "dry" means at or below 19% moisture content and most reports say that hardwood is dry at about 10% (there is no definitive standard for hardwoods). BUT ... it is important to realized that moisture content varies greatly with location and "dry" in Arizona and "dry" in Florida do not and should not mean exactly the same moisture content.

dry rot --- (1) The condition of wood that has undergone brown rot but which is now dry. During the process of rot, the cell structure of the wood was broken down and when the moisture that was necessarily there during the rotting process evaporates, what is left is a highly friable substance that can be crushed to powder with very little pressure. The term is somewhat incorrect in the sense that it seems to imply a process of rot that occurs WHILE wood is dry, which is impossible; all organic decay processes require moisture. Wood that has progressed to dry rot is often white. The "dry" in the term stems from the mistaken belief hundreds of years ago that this particular rot occurred without the presence of water. The process often happened in ships timbers and wasn't observed until it had turned to dry rot, and since it can happen from the interior outwards on large timbers, it was seen as a particularly nasty form or decay since it seemed to appear all at once with catastrophic results. This is what leads to the second definition:

dry rot --- (2) In non-wood terms, dry rot is used as a metaphor for grave underlying problems within large organizations such governments that show no symptoms until a sudden, catastrophic failure, much as dry rot of wood in ships caused catastrophic failure with no prior warning.

dry seasoned --- see dry lumber

dry set --- Masonry that is laid without mortar

dry to tack free --- A stage at which a finishing agent will form a skin to which dust will not adhere.

dry to touch --- The state of dry at which a finishing agent will not transfer onto an item touched lightly against it.

drywall --- (1) A common manufactured building material used globally for the finish construction of interior walls and ceilings. Usually made out of gypsum plaster encased in a thin cardboard or heavy paper sheathing, it is nailed or screwed (with a drywall screw or a reverse thread drywall screw) to wall studs and then the joints are covered over with a special tape ("dry wall tape") and then covered further with a joint compound to make the joints invisible. The screw heads are also covered with the same compound as are any nail heads.. The wall can then be painted or wallpapered over or covered with paneling. Also called "gypsum board" and "wallboard".

drywall --- (2) Wall covering other than that described in definition (1) above, such as plywood or hardboard, which is applied to interior walls in large panels.

Example of type (1) above, with tape applied to the joints and compound applied to both the joints and the screw heads, but no further finishing done:

drywall screw --- As the name says, this kind of screw is designed for use with drywall so it doesn't have to be very strong and thus they are generally pretty skinny. Thay are always flat head screws so as to be flush with the drywall surface, and they are countersunk in a curved fashion (often called a "bugle" head) so as to not abruptly the drywall as they go in. They also seems to always use a phillips head drive type, probably because if the screwdriver slipped off of a flat head drive type it could poke a hole in the drywall and the shape does not lend itself to the use of a robertson drive. They typically are made of steel, sometimes with a black finish and have quite coarse threads and they are sometimes a type of self tapping screw since on the other side of the drywall they have to go into a stud; for the same reason, they often have a very sharp point if they are not self tapping. Unlike more normal wood screws the outer diamter of the threads on these screws is larger than the unthreaded shank. Compare/contrast to particleboard screw and see also reverse thread drywall screw. Examples:

dry weight --- synonymous with oven dried weight

dry well --- This is not the kind of well where you are digging for water, but rather a hollowed our area in the ground that is filled with rocks and designed to collect rainwater and divert it from the foundation of a building.

duck tape --- A, to my mind, disgusting bastardization of the term duct tape. There are some vendors who are so infantile that they actually use that name for their product (or maybe they are just so ignorant that they think it's the correct spelling, but I doubt it). BUT WAIT: alert reader Kįri Haršarson told me that actual "duck (canvas-backed) tape" does exist so I did a search and found that the tape now called "duct tape" was first made as "duck" tape and was cloth ("duck cotton") backed and later canvas ("duck canvas") backed starting in the early 1900's and only in the 1970's after it was widely used to wrap air ducts did the name change to "duct tape" and since then that has been the common name (and "duck" cloth/canvas apparently is no longer used) so my statement about the modern use of the term "duck tape" stands but "duck" tape is an interesting historical footnote.

ductile --- Describes materials that can be subjected to large stretching strains before rupturing; usually used to describe metals such as copper that can be stretched into a fine wire, as opposed to cast iron which cannot. Compare/contrast to brittle.

duct tape --- A fabric-reinforced, pressure-sensitive, multi-purpose tape, generally gray in color and 2 1/8" wide. Developed during WWII, it became widely used afterwards on heating and air conditioning ducts, thus the current name. Its versatility makes it a household staple item. There is a joke that says you really only need two tools in life, duct tape and 3-in-1 oil. If something moves when it shouldn't, apply duct tape and if it doesn't move when it should, apply 3-in-1 oil.

ductwork --- A system of hollow metal or plastic tubes or conduits used to distribute warm air from a central furnace throughout a building. In homes, ductwork is normally quite modest in size but in large buildings it can be large enough for a person to crawl inside of (a fact that is often made use of in movies).

dulling --- (1) Loss of gloss on the surface of a finishing agent; lowered reflectivity.

dulling --- (2) Reduction in sharpness of a cutting edge. The speed with which any particular wood causes dulling is an important characteristic of the wood. Most woods are low or moderate in how much they cause dulling, but some exotics, and particularly any woods that are high in silica, can cause rapid dulling, particularly of high speed router bits.

duplicating lathe --- A mechanical device that allows a lathe to make repeated identical copies of a turning by controlling the motion of the cutting tools.

duplicator --- In woodworking, this term usually means a duplicating lathe.

durability --- (1) The ability of wood to resist mechanical wear, particularly when in high-abrasion uses such as flooring, mallets, etc. This is a function primarily of toughness but also somewhat of hardness.

durability --- (2) The ability of wood to resist the attacks of foreign organisms, such as fungi, insects, and marine borers under conditions that favor such attacks. The main reason for the natural durability of some wood species is the presence of substances that are toxic to decay-causing organisms. In general, the heartwood of most species is more durable than the sapwood. In researching for this glossary, I encountered several classification systems for durability against attacks of foreign organisms and while they are not in exact agreement, they are generally something like this, and note that these are for untreated heartwood stuck in the ground (untreated sapwood is assumed to be perishable):

- very durable: greater than 25 years

- durable: 15 to 25 years

- moderately durable: 8 to 15 years

- slightly durable: 4 to 8 years

- perishable: less than 4 years

dust collector --- A motorized suction system designed to filter fine wood particles from cutting and sanding operations out of the air in a workshop, and to help avoid the accumulation of dust piles around the various machines. Typically, the motor and collection bag(s) are in one location and connected by large gated tubes to various woodworking machines. Often a chip collector with blast gates are positioned near the motorized section to shut off the suction to unused machines thus improving the efficiency of the system.

dust nibs --- A surface defect in a dried finishing agent caused by small particles settling on the surface of the finish as it was drying, before a film had formed on the surface; can usually be repaired by sanding level and recoating or rubbing out.

dust panel --- A thin horizontally mounted panel that protects the contents of a drawer from the dust created by the drawer above rubbing on its runners.

dutchman --- synonymous with butterfly

dwang --- synonymous with nogging (but this term seems to be used only in English speaking countries OTHER than the USA)

dye --- As regards woodworking, this refers to any type of coloring agent that soaks into the fibers of wood instead of being left on top the way some thicker finishing agents do. It is used to evenly color wood before putting on a protective finishing agent. Personally, I think that anyone who dyes OR stains wood should be shot. The main difference between a stain stain and a dye is the size of the particles of the pigment. Stains are more or less watered down paint with large pigment particles that sit on the wood and give it color but at the expense of obscuring the grain. Dyes have extremely small particles of pigment; so small that light actually passes through them. Dye particles are so small that they soak way down into the structure of the wood at a molecular level rather than sitting on top of it and yet they still change the color while having very little effect on the appearance of the grain.

dye wood --- a species where the wood has water soluble pigments that will flow out into the water when the wood is boiled, thus creating water that can then be used to dye other substances, usually fabric. African padauk and osage orange are examples of dye wood.

early growth --- That portion of tree growth that occurs early in the year (spring and early summer) and is also called "spring growth" and "spring wood" but those terms are deprecated because early and late growth in tropical zones are more the result of rainy seasons than a non-existent summer/winter cycle. This wood tends to be less dense, wider, weaker in strength, and lighter in color, than the late growth.

early wood --- synonymous with early growth

ears --- The outside edges of wood carving tool blades.

earth auger --- synonymous with soil auger

earth ground --- See ground

ease --- To slightly "soften" the sharp edge on a piece of wood by rounding it off slightly or giving it a slight bevel.

eased edge --- A lightly chamfered or lightly beveled edge.

eave --- The edge of a roof that extends beyond or overhangs a wall; the roof edge from the fascia to the structure's outside wall. Examples:

eave soffit --- A soffit that is placed under the eaves of a house (as opposed to any of the OTHER places which can take a soffit, and which are not yet discussed in this glossary).

eave trough --- synonymous with gutter

eccentric --- Off center; see eccentric load

eccentric load --- Loads that are applied off the central axis of a structural member, or loads that have a center of gravity that is off-center from the central axis of a spinning device such as a wood lathe. Eccentric loads are generally a bad thing, but sometimes necessary.

edge --- see plank

edge banding --- [noun] Veneer strips used to cover the exposed edges of panel products such as plywood or other composite material edges (for example, on face frames). Such veneer is usually available in rolls and is available both pre-glued and unglued. Wood strips, generally 1/4" and thicker, used for the same purpose, are sometimes also called edge banding, but should more properly be called edging.

edge banding --- [verb] The process of putting on the material as described above.

edge full lap --- A full lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. As can be seen in the examples below, the joint can be half blind or through. Examples:

edge grain --- synonymous with side grain and does NOT have the same meaning as edge grained.

edge grained --- synonymous with quartersawn because in quartersawn planks, the "flat" face (that is, the tangential surface) is actually on the edge of the plank, not on the wide face as it is on flat cut planks. Compare/contrast to side grain, end grain, and face grain.

edge guide --- A straight edge that is used to guide a tool, such as a circular saw or router, along a workpiece. This could be something as simple as a 2x4 clamped to a panel of plywood, or it could be a specifically fabricated strip of metal or plastic with one flat edge and enough stiffness to keep the tool from moving off of a straight line.

edge half lap --- A half lap joint where the two mating pieces are presented to each other edge to edge instead of face to face. As can be seen in the examples below, the joint can be half blind or through. Examples:

edge joining --- Squaring the edges of two boards and gluing them together in an edge joint.

edge joint --- A joint made by bonding two pieces of wood together edge-to-edge, commonly by gluing. The joints may be made by gluing two squared edges as in a plain edge joint or by using machined joints of various kinds (e.g. tongued and grooved). A plain edge joint (with just flat abutted edges) is also called a butt joint.

edgemark --- An APA trademark stamped on the edge of a panel. See also backstamp

edge miter cut --- see miter cut

edge miter joint --- A joint where the edge of one plank meets the edge of another plank at 90 degrees and each edge is cut with a (normally 45 degree) miter cut. Compare/contrast to edge rabbet. If reinforced with a spline, then the joint is a splined edge miter joint. Examples: