|

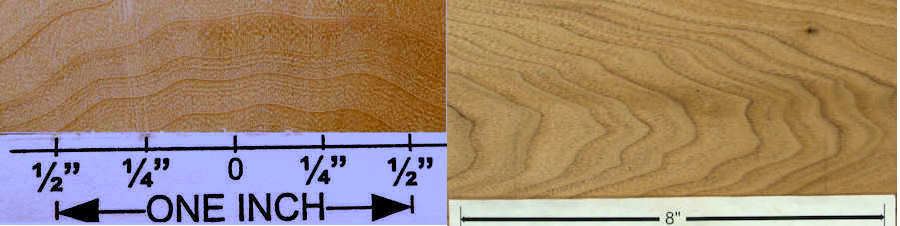

A note about "grain" and "figure". These terms are sometimes used interchangeably in a way that I believe to be incorrect. In this glossary, I take a point of view which I believe is the "correct" one, but I want to acknowledge that it is opposed to that taken by some, including a man whom I consider very much my better in regards to knowledge of wood and that is Dr. Bruce Hoadley who has written two books that are widely, and I believe appropriately, considered to be the definitive works in their field. These are "Identifying Wood" and "Understanding Wood". On this particular issue, I have a strong and supportable reason for differing with Dr. Hoadley.

For a full discussion of the two points of view, and the statistics that validate my own point of view, click here: figure vs grain. I don't put the whole thing right here because this box is already too big. Had this difference of opinion been with anyone other than Dr. Hoadley, I would simply have ignored them and gone on my way and would not have subjected my readers to this diatribe. However, I think that regarding ANY other information about wood, anyone who ignores Dr. Hoadley is being foolish. As young people say these days, when it comes to knowledge about wood, "He da man". |

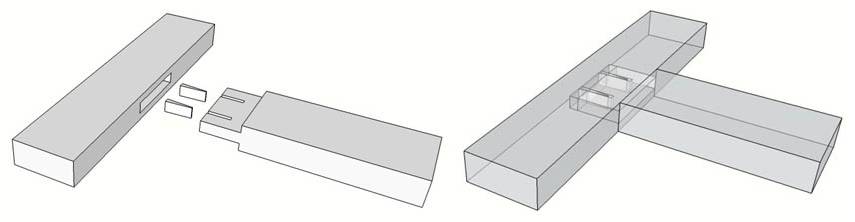

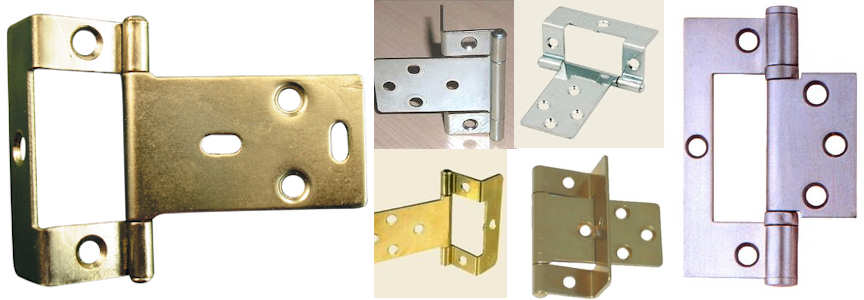

need to add flush hinge pics

need to add flush hinge pics