The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

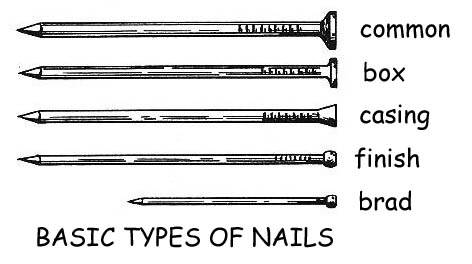

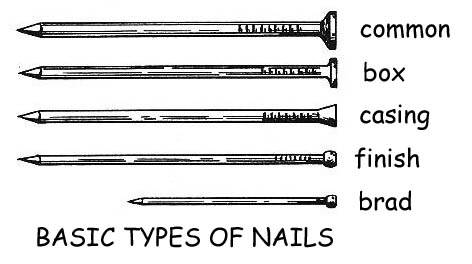

nail --- A long, skinny, metal fastener used to join pieces of wood or to join other objects to wood. There are numerous types of nails and they can be made from various types of metal. Nail length is normally measured from the underside of the head down to the point. The most basic nail types are categorized by shape, as opposed to coating (for which see the following list), size, or other characteristics. These include:

- annular ring --- has ridges around the circumference for extra holding power

- brad --- a very small, thin nail; will have either a common nail style head or a finishing nail style head, and is a type of wire nail.

- box --- same shape as common but smaller in diameter and head size for a given length

- casing --- similar to finishing nails but with a slightly larger head; often used for flooring, where a finishing nail doesn't have quite enough holding power but a common or box would have too large a head

- common --- used almost exclusively for construction, they have a broad head for good holding power and a hefty shank for good shear strength. Normally a type of wire nail.

- concrete --- same a masonry

- cut --- stamped from sheet steel; has a flat end and a rectangular cross section

- duplex --- same as scaffolding

- drywall ---

- finishing --- has a very small head and thus limited holding power, but can be sunk into the wood and covered with wood putty. Finishing nails are a type of wire nails (see further discussion below the drawing)

- flooring --- Sometimes referred to as "cleats," these are special nails used in a flooring nailer. They are either "L" or "T" shaped to fit snugly into the right angle of the tongue protruding from the side of a flooring plank

- framing --- Same sizes as common but with a grooved head

- gutter spike --- long nail specifically used to attach gutters

- helix --- the nail has a square shank that has been twisted, making the nail very difficult to pull out after it is driven in because of the way the spirals grip the wood; often used in decking.

- horseshoe --- not used in woodworking

- lath --- slender nail used to attach lath to studs (it's skinny to avoid splitting the lath)

- lost head --- another name for finishing nail

- masonry --- hardened steel for driving into masonry

- horseshoe --- not used in woodworking

- ring shank --- same as annular ring

- roofing --- has a broad head so roof shingles won't pull through

- scaffolding --- a common nail but with two heads so that the nail doesn't go all the way into the wood and it is very simple to insert a claw hammer's claw and remove the nail; used for temporary scaffolding, thus the name.

- screw shank ---

- sinker --- a thin framing nail with a conical head

- spike --- general term for very large nails

- spiral --- has a spiral ridge along the shank for extra holding power

- tack --- short, broadheaded, highly tapered, used for carpet and upholstery

- umbrella head roofing nail --- exceptionally broad head

- upholstery --- short, with a broad, fancy head

- wire --- can be many of the other types discussed, but so named because the fabrication process involves using wire as the starting point. Common nails, box nails, and brads are all usually wire nails.

Other nail names based on the finish rather than the use and that may apply to more than one basic type of nail. For example, there are bright common nails and bright finishing nails

- bright --- has no surface coating to inhibit corrosion, so it's shiny, thus the name; not recommended for weather exposure or acidic or treated lumber. The opposite of "galvanized" nails.

- cement coated --- adhesive coating gives extra holding power

- electrogalvanized --- provides a smooth finish with some corrosion resistance but has less zinc deposited on the surface that mechanically galvanized nails

- galvanized --- treated for resistance to corrosion and/or weather exposure (the opposite of "bright" nails)

- hot dip galvanized --- first given a rough finish that deposits more zinc than other methods, and then galvainzed, resulting in very high corrosion resistance that is suitable for some acidic and treated lumber; often easier to bend than other types of nails

- mechanically galvanized - provides more zinc deposited than electrogalvanizing for increased corrosion resistance

- phosphate coated --- treaded with a dark grey to black finish providing a surface that binds well with paint and joint compound and minimal corrosion resistance

- resin coated --- (and vinyl coated) given a coating that melts from friction when the nail is driven so as to help lubricate the insertion. The coating then hardens. These nails come in various colors from different manufacturers (tan and pink are common).

- siding nail --- treated in some way so as to not leave any stain on home siding due to weather

- vinyl coated --- see resin coated

- wrought head --- designed to look like the hand-forged nails of the late 1700s, and used primarily for antique restoration.

nail glued --- A joint that is both glued and nailed to provide double holding power and/or so that the nails provide clamping pressure to the joint while the glue sets.

nail gun --- A hand-operated power tool which drives nails from a carrier strip. "Framing nailers", which drive framing nails are Widely used in the construction trades and has pretty much replaced the framming hammer. "Finish nailers" drive finishing nails and "brad nailers" are for really small nails/brads. Examples:

nail head --- The top of a nail; the portion of a nail that is struck by a hammer. The two most fundamental characteristics of a nail beyond the material it is made from (usually steel) are the shape of the body and the shape of the head. Head shapes range from a very wide flat cylinder on a roofing nail to an almost non-existent head on a finishing nail.

nail holding strength --- One of those poorly defined (in precise technical terms) characteristics that is always mentioned in any full discourse on the properties of wood. It refers to the degree to which the wood tends toward ease or difficulty in removing nails once they have been inserted. Wood that has poor nail holding strength would obviously be a poor candidate for nailed joints. End grain in most woods has poor nail holding strength, some extremely poor. Nail holding strength, when mentioned, normally refers to face and side grain holding strength, not end grain.

nailing plate --- A section of wood attached to metal or masonry so that framing members can be nailed to it. Not to be confused with a nail plate.

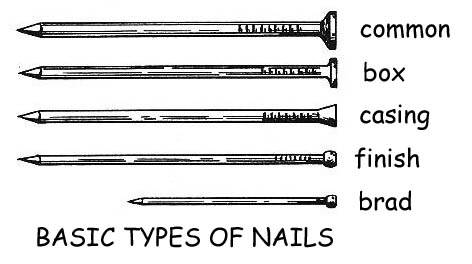

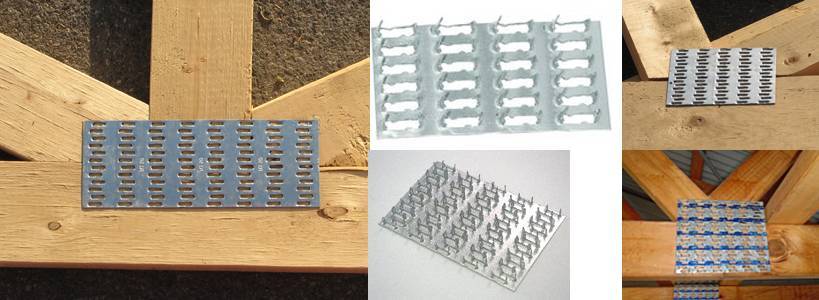

nail plate --- A sheet metal plate stamped so that spikes are formed on one side to grab like nails when the plate is pressed into timber to join two pieces. Widely used in prefabricated roof trusses. Not to be confused with a nailing plate. Examples:

nail pop --- The situation where a nail comes partly out of the surface it has been driven into. This usually occurs because of changes in wood due to changes in moisture in the surrounding air. The nail itself may show above the surface it is nailed into or it may cause a bulge in an overlying surface (e.g. linoleum that has been bonded onto nailed-down subflooring). When wall studs shrink due to moisture loss, a slight gap may be created between the stud and the wallboard and if someone then leans against the wall, a wallboard nail will pop out of the surface slightly. If flooring flexes, nails can be worked out of position over time by mechanical vibration.

nail puller --- Nails can be pulled with a very wide variety of devices, most commonly the claws on a claw hammer or on a small crowbar, but there are two stand-alone devices that are made exclusively for pulling nails (unlike the claws on a claw hammer, which are part of a multi-tool which both puts nails in and takes them out) and these are the nail puller, discussed here, and the claw nail puller which has its own entry in this glossary. The nail puller has a sliding handle on one end and a pair of sharp jaws on the other end. The jaws are set on both sides of the nail and then the sliding handle is slid up and then sharply down, forcing the jaws into the wood around the nail. The handle is then pulled over a lever that goes off to one side of the jaws to give great leverage to the pull AND which is attached to one of the jaws thus causing the leverage to also tighten the jaws as the nail is pulled. This tool leaves a mark or marks on the wood, but it DOES get the job done. Examples:

nail punch --- A metal rod with a tapered end, used to drive nails so that their heads go below the surface of the wood. This is not normally used with common nails, which have a large head, but it is used with box nails and brads and most particularly with finishing nails. With finishing nails, the nail punch typically has a concave tip that just fits the head of the nail, because finishing nails are used where the finish is important and you don't want the nail punch to slip off and mar the surface. Nails punches are frequently sold in sets with different size and style tips to fit various nails. Also called "nail set", not meaning a set of nails but something that "sets" the head of the nail. Really small finishing nails and brads are set with brad setters. Examples:

nail ring --- A generally rectangular pattern of nails used to join timber elements.

nail set --- synonymous with nail punch

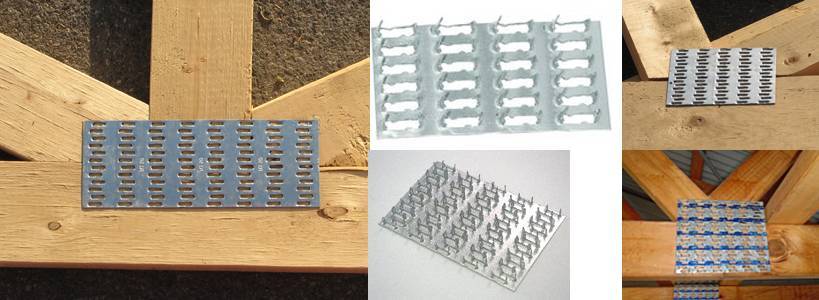

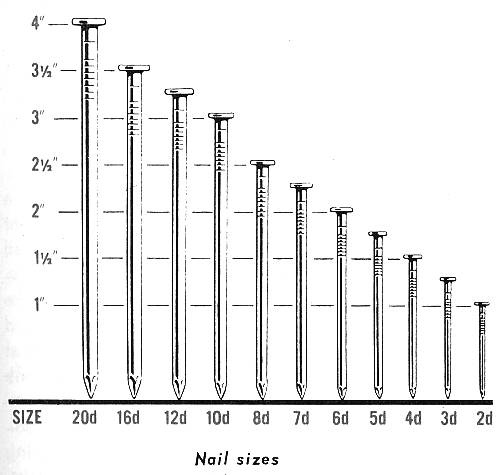

nail sizes --- Common nails are sized by an archaic system based on how many old British pennies it took at one point to buy 100 of them, and the symbol for penny is the letter "d". What the ??? you say ... can't the British even SPELL? Well, yes, they can. They can also speak Latin, or used to be able to, and the "d" comes from the Roman name for coin (denarius), not a British penny. It's sort of like the story about why American railroad ties are THIS far apart but that's another story. ANYWAY, it took more pennies to buy 100 of the bigger ones than 100 of the smaller ones, so bigger ones have bigger "penny numbers"; see the chart below which shows the approximate diameter and the length in inches of the normal sizes. Note that the length does not count the head. I have sized this image so that on my monitor, which is set for 1280x800 pixels, the nails are almost exactly full size. I have had no luck for many years now in buying any 2d nails. No one seems to stock them any more. There are penny sizes above 20d ... I'm sure I have some 30d and 40d around and I remember buying some 60d at one point years ago (although I can't remember WHY I bought them ... damned things are almost as big as railroad spikes!). Really big nails are in fact called spikes.

naphtha --- An ambiguous term used to describe any of various volatile flammable liquid hydrocarbon mixtures that are used chiefly as solvents to thin finishing agents (primarily paint and oil based finishes) and to clean up after painting.

narrow fluted parting tool --- see fluted parting tool

narrow grained --- synonymous with tight grained

National Evaluation Service --- An organization sponsored jointly by three major American model code organizations (see model code for details) to evaluate new products for the three constituent members.

National Grading Rule Committee --- [NGRC] An autonomous body functioning under bylaws approved by the American Lumber Standard Committee. It has specific functions with regards to maintaining the grading rules for dimension lumber.

National Hardwood Lumber Association --- [NHLA] An organization founded over 100 years ago (1898) to establish a uniform system of grading rules for the measurement and inspection of hardwood lumber, and which to represents over 1600 members from all sectors of the hardwood industry. It develops and promulgates standards and rules that are employed worldwide.

natural edge --- An unfinished edge of a wooden object that retains the outer portion of the tree; a term most often used in describing the lip of a turned bowl in which the natural outer edge of the tree, often (but not necessarily) including the bark, is left untouched. Examples:

natural edged lumber --- Boards having a natural edge on one or both edges.

natural finish --- synonymous with natural polish. I don't know why the term natural finish (which I think of as referring to any finish, without regard to shine) is preferred in woodworking to natural polish (which I think of as referring to shine), but it is even though the effect being discussed by the term is not really just finish, which is a fairly general term, but polish, which is a more specific term. That is, whatever the state of the wood is before any chemical is applied is the natural finish of the wood, but that is NOT what is being referred to by this phrase; this phrase is referring to the ability of wood to take a hard, shiny finish without the use of chemicals, and to me that should always be referred to as natural polish, not natural finish. As always, however, I don't get to make the rules, I just report on them.

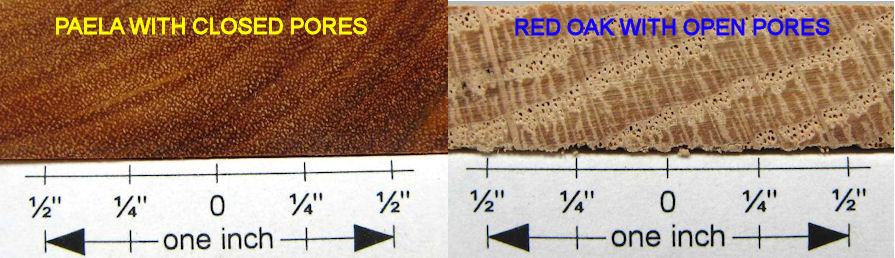

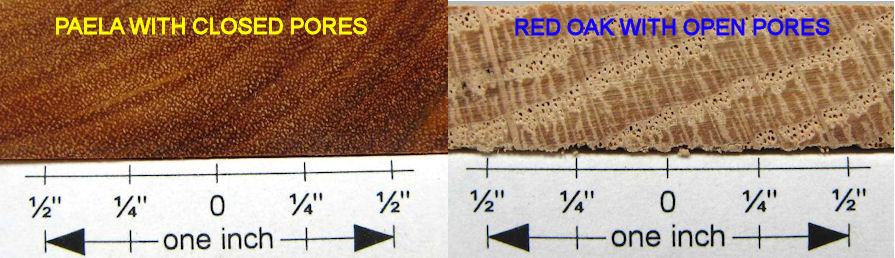

natural polish --- The degree to which a wood can be brought to a hard, bright surface without any kind of filler. Hardwoods with very tiny-diameter vessels (such as snakewood) take the highest natural polish whereas woods that are soft (such as cottonwood) or that have large open pores (such as red oak) take a poor natural polish either because they tend to fuzz up (the soft woods) or they are grainy (large open pores). Here's a composite pic which shows two pieces of black walnut. Walnut is a medium texture, slightly grainy wood, and as seen on the right takes a low to moderate natural polish, but take a piece of very dense walnut crotch wood and as you can see on the left, it can be brought to a very high natural polish.

naval stores --- A term applied to the oils, resins, tars, and pitches, exuded by, or extracted from trees, chiefly species of pine . Historically, these were important items in the stores of wooden sailing ships where they were used for various purposes.

NE --- Natural Edge

NEB --- Natural Edge Bowl (see natural edge)

needle files --- Very small files. This designation is based on size, not shape or fineness of cut, and they are intended for filing metals. Examples:

needle nose pliers --- A type of pliers used primarily in electrical work but so generally useful that woodworkers usually have a pair or three laying around. They have long skinny jaws (thus the name), usually serrated, and are very handy for bending wire and for placing wire onto electrical connections, but they have a thousand other uses. The length and exact shape of the jaws will vary from brand to brand and many sizes and styles are made. A version with a bend in the jaws is called bent nose pliers Examples:

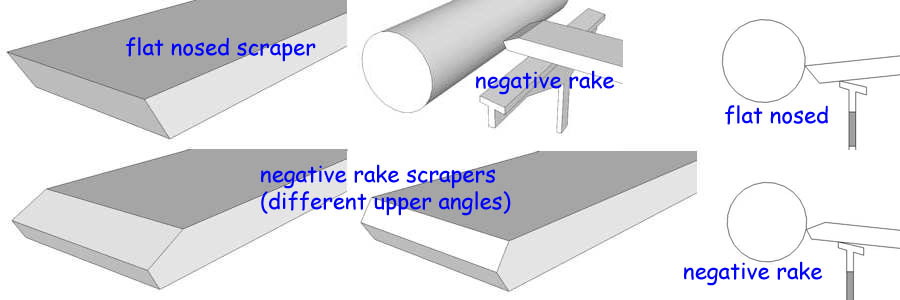

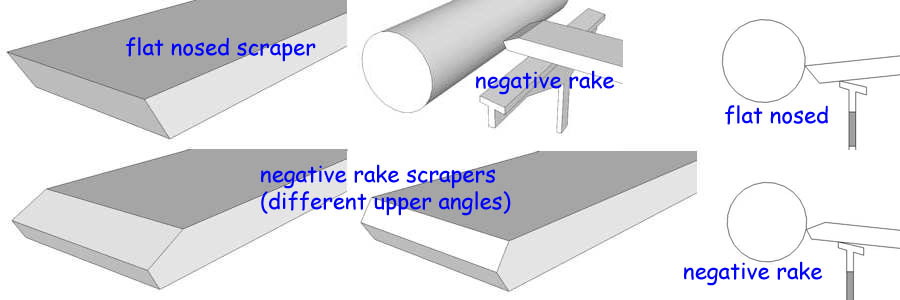

negative rake scraper --- A lathe tool that is a normal flat nose scraper with part of the top ground off so that both the top and bottom come off the shank at an angle. This reduces the "grab" of the scraper but the main characteristic is that it reduces the amount of material removed, and is thus very much a finishing tool, and would not be at all effective for hogging. It also allows the handle to be below the burr instead of above it, which some turners feel gives better control for fine finish turning. At the time of this writing, I have it on anecdotal information that there are not yet any vendors producing negative rake scrapers, so turners make their own by grinding off a large bevel on the top side. These tools are ideal for finishing scrapes on very hard wood and have been used for centuries by luthiers, who apparently make their own. A similar effect can be had by turning a skew chisel flat on its side and using it as a scraper, but skew chisels have a much sharper edge and are thus less amenable to a stable burr. Examples:

NES --- National Evaluation Service

nesting --- Having similar object one inside the other, like Russian dolls. In woodturning, it refers to bowls that have been created in a series of sizes so that they all fit inside each other (in order of size).

net lumber tally --- lumber measured in board feet after kiln drying. Compare/contrast to gross lumber tally.

newel --- The vertical post at the top and bottom of a staircase where the banister is supported. Newels are always thicker than the staircase balusters and banisters. Examples:

newel post --- synonymous with newel

NGRC --- National Grading Rule Committee

NHLA --- National Hardwood Lumber Association

nitrogen --- A colorless, odorless gaseous element (#7 on the periodic table) that makes up most of the earth's atmosphere (almost 80% of it) and also exists in the soil in a couple of combined forms, whence it is sucked up by plants, including trees, as a key element in their growth processes.

node --- The meeting point of two or more members of a truss. The members at the node have to be joined in some way. In prefabricated trusses used for residential construction, this is commonly done with nail plates. In site-built trusses there are numerous techniques for joinery.

nogging --- (1) Horizontal support bracing between studs or floor joists and made of timber, masonry, or metal. This seems to be a term used mostly with log construction and not much used with framing that uses dimension lumber.

nogging --- (2) bracing put between roof trusses to be used as mounting surfaces for ceiling material.

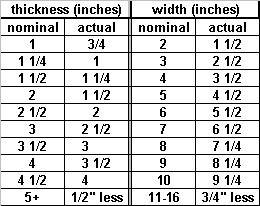

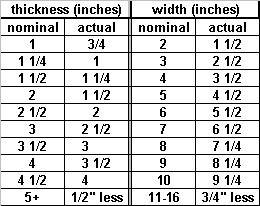

nominal size --- Literally nominal means "in name only"; in normal English language usage, it means approximate and sometimes has the connotation of "not including some particular consideration" [nominal interest rates, for example, do not discount for inflation], and it has that connotation in the world of wood as well and the consideration that "nominal size" doesn't account for is the wood removed during surfacing. Technically, this is called the "rough-sawn" (as opposed to actual) size of a piece of lumber but the term nominal is used far more often than rough-sawn. When purchasing planed lumber it is sold by its nominal size in quarter measure. For example a 2"x4" is the nominal size for a board whose actual dimension is 1 1/2" x 3 1/2" and a "one-inch-thick" plank is the nominal size for a board that has been surfaced to 3/4". Another way to say it, and an easy way to remember it is that a "two-by-four" is 2" by 4" IN NAME ONLY (that is, nominally, not in actuality; in actuality it's 1 1/2" x 3 1/2")

This has a couple of significant implications, one involving pricing (board feet) and the other involving weight. Because the size of what you buy is not the size it says it is, you have to be careful in calculating board feet. You are BUYING an amount of board feet that is based on the NOMINAL size, not the actual size, and you are therefore paying for wood that is out behind the lumber yard in the form of sawdust. But the WEIGHT of what you buy has to be based on the cubic feet of the ACTUAL size, not the nominal size since it is not the nominal size that has to fit into your pickup truck, it is the actual size. That is, you BUY the nominal size but you GET the actual size.

If you calculate your cost based on ACTUAL size, you will find that you have paid 33% more for 3/4" planks than you thought you did based on what the lumber yard said they were charging per board foot because they are charging you for 1" thick boards and selling you 3/4" boards. On the other hand, if you take the board feet that the lumber yard says you bought and you convert it to weight based on the pounds per cubic foot of the wood species you bought, you will come up with a weight that has to be reduced by 25% (based on 3/4" boards) to get the weight that actually goes into your pickup truck.

Lumber that is used in the building construction industry, normally called dimension lumber, and always made from softwoods is always sold in, and referred to in, the nominal sizes and really, none of the above discussion has much relevance since carpenters become accustomed to all that very early on. Hardwoods may be sold in nominal size or actual size, but are far more likely to be sold in nominal size than actual size because that way it sounds like you are getting more for your money than you are really getting. Below is a table of nominal vs actual sizes for dimension lumber. As you can see, in the smaller ranges, the actual is 1/4 less than the nominal and at 2" and over, the actual becomes 1/2 less than the nominal.

no mortise hinge --- Could refer to any surface mounted hinge but usually is synonymous with bifold door hinge.

non-bearing --- Not supporting any load other than its own weight.

noncertified --- Structuralpanels or other composite material items that are not certified by any recognized testing agency.

nonferrous --- Materials and metals not made of or containing iron, and therefore not subject to rust. such materials commonly used in a wood shop include aluminum, copper, brass and lead. Compare/contrast to ferrous.

nonpiloted bit --- A router bit that does not have a pilot bearing. Compare/contrast to piloted bit.

nonporous --- As regards wood, it means having no pores, which is a condition of softwoods. Hardwoods do have pores. see porosity. In standard English, porosity is a characteristic of a material's inability to pass fluids but as regards wood, it is not used in that way (impermeable is the correct term).

nonstructural --- Having to do with something that is not integral to the strength of an item such as a building or a tree but which is needed for some reason. Nonstructural items MAY be decorative but generally if something is specifically decorative, then that term is used to describe it whereas "nonstructural" carries a connotation of "not decorative; needed but not directly contributing to strength".

nonvolatile --- [also non-volatile] Not subject to high rates of evaporation. This term is used in woodworking to describe the portion of a finishing agent that remains after any volatile portions have evaporated.

Northern hardwood forest type --- A forest type common to the Northeastern United States; it includes sugar maple, red maple, yellow birch, hemlock, and American beech.

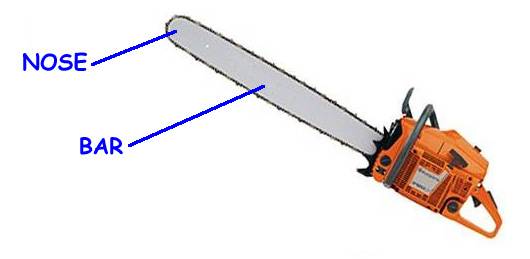

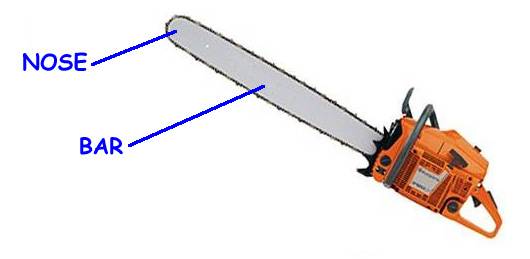

nose --- The rounded end of the bar on which a chain saw blade rides. Improper use of the bar by way of attempting to cut starting with the nose can result in kickback. Example:

nosing --- The rounded front edge of a stair tread that extends over the riser.

notch --- A "V" shaped groove in a wood surface, generally perpendicular to the length of the piece but that is not a required part of the definition. Log cabins are built by cutting large notches in the ends of the logs so that the stack firmly. Wood carvers use various tools for creating notches as they carve. Large V-shaped cuts in the ends of construction members (e.g. joists and rafters) are also called notches. Old West gunslingers supposedly notched the handles of their six-shooters once for every man they killed (I'm not sure what they did if they killed a woman). The term is sometimes loosely applied to grooves that have shapes other than a "V" cross section. In sloppy, casual use, it sometimes incorrectly describes slots, which are similar but have a rectangular cross section (and which should be CALLED slots, not notches).

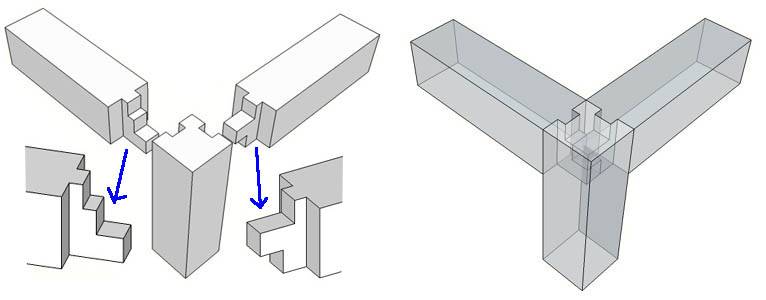

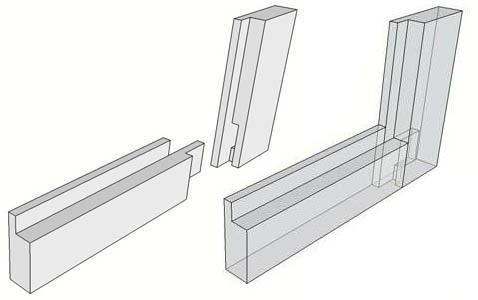

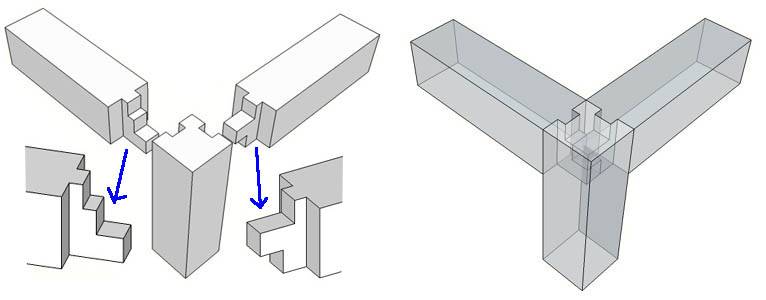

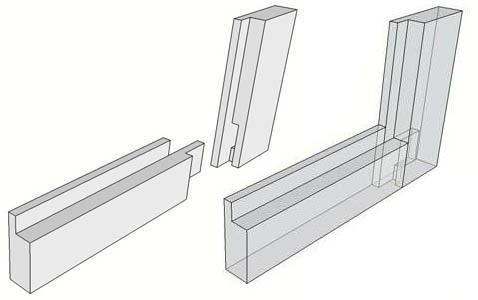

notched mortise and tenon --- This is a standard blind mortise and tenon joint but with a twist, which is that the piece with the mortise receives tenons from two directions and the tenons are cut so that one fits partly over the other, thus allowing them both to penetrate into the mortise as far as possible for maximum strength. Although the example shown below is drawn as an open mortise and tenon (see bridle joint, it obviously does not have to be open. A variation on this type joint is the mitered tenon. Examples:

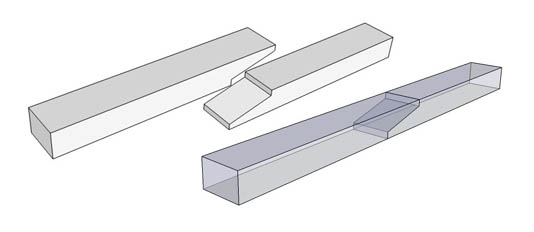

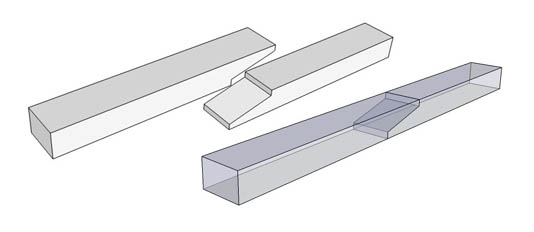

notched scarf --- This is a very minor variation on the standard scarf joint, made by cutting off the sharp ends. Examples:

NPT --- National Pipe Thread; a standard for pipe threads.

number one common --- [#1 Common] A high NHLA grade for furniture manufacturers and cabinet shops. This grade requires a clear face cutting yield of 2/3rds up to 5/6ths.

nut --- A (typically) square or hexagonal piece of metal with a hole threaded through it to accept a bolt. When the two are screwed together tightly, compressive force increases the friction at the threads such that the two do not normally come apart. Since vibration can sometimes loosen a nut, a split ring lock washer can be used under the head of the bolt to maintain the compressive pressure in the threads to prevent that from happening. There are actually quite a variety of fasteners that are called nuts other than just the common square and hex types. A couple of them are shown in the composit image below. The item that is what is most normally meant by the term "nut" is formally called a machine nut. See also bolts vs screws. Below is a composite pic showing many of the types of nuts, followed by a list of the most common types used in woodworking or related metal working, linked to more extensive definitions and pics.

- acorn nut --- a cap nut with an acorn-shaped, decorative dome

- cap nut --- a hex nut topped by a dome or closed cylinder

- captive washer lock nut --- see lock nut

- castle nut --- one side looks like castle battlements

- coupling nut --- joins two threaded rods

- flanged cap nut --- cap nut with flange

- flange nut --- has a flange for extra pressure distribution

- flat speed nut --- see spring nut

- hex coupling nut --- see coupling nut

- hex head nut / hex nut --- see machine nut

- insert nut --- synonymous with threaded insert

- jam nut --- thin hex nut used to jam onto another nut for locking

- lock nut --- various kinds of extra-holding-power nuts

- lug nut --- a cap nut used to hold car tires on, not used in woodworking

- machine nut --- what is normally called a hex nut or a square nut

- nylon lock nut --- see lock nut

- push nut --- see spring nut

- rod coupling nut --- see coupling nut

- round coupling nut --- see coupling nut

- serrated flange nut --- flanged nut with serrations on the botton of the head

- speed nut --- see spring nut

- slotted hex nut --- same as castle nut

- split nut --- a nut that can be separated into two halves (sometimes hinged)

- spring nut --- specialty type that has a springing action

- square head nut / square nut --- see machine nut

- T-nut --- specialty woodworking nut; doesn't turn, grabs the wood

- U-nut --- see spring nut

- wheel lock nut --- same as serrated flange nut

- wing nut --- two wing-like projections that allow you to turn in like a thumb screw

nylon insert nut --- see lock nut

nylon lock nut --- see lock nut

oak-gum-cypress forest type --- A forest type common to the bottom lands of the Southeastern United States.

oak-hickory forest type --- A forest type common to the Northeastern United States; it includes oak (red and white), hickory, yellow poplar, and red maple.

oak-pine forest type --- A forest type common to the Southeastern United States; it includes loblolly pine, Virginia pine, northern red oak, and white ash.

OC --- On Center

OD --- Outer Diameter. Compare/contrast to ID

off grade --- lumber that does not conform to the grade it was represented as being.

offset shoulder mortise and tenon --- A type of joint that can be used when planks are to be used to hold a mirror, for example. The planks are given an edge rabbet on what will be the rear surface and then a mortise and tenon joint is used to mate them securely. When this is done, one of the shoulders of the tenon is offset from the other to accommodate the rabbet, thus the name of the joint. Here is the rear view of one corner of a mirror frame that is done in this fashion:

offset turning --- Turning objects on a lathe in a way such that for some portion of the length of the workpiece while turning, the center line of the object is NOT in line with the centerline of the lathe. One or both ends of the object are positioned such that their center is offset from the turning center of the center or chuck. Think of the crankshaft of a car. In woodworking, this is done for decorative effects.

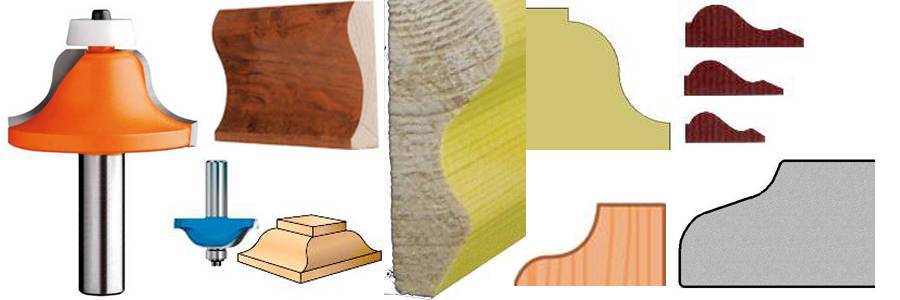

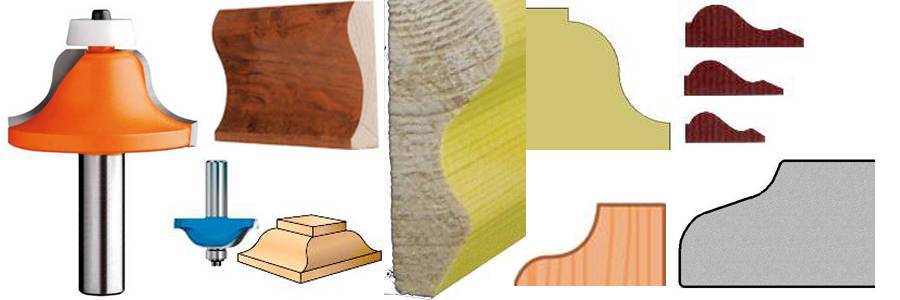

ogee --- A shape (usually referring specifically to molding with a double curve which in cross section looks like a shallow letter "S" with the convex part above and the concave part below. In architecture, an alternative name for ogee is cyma reversa. The plural of ogee is given variously as ogges, oggez, and ogeez, which for some reason I find hilarious. There are router bits specifically designed to cut this shape. Examples:

ogee washer --- a large cast iron washer with an ogee-shaped rim. This is typically used in very heavy construction such as bridge-building because the large bearing surface prevents bolt heads from pulling into the wood under high load. This is an even more heavy-duty construction washer than the dock washer because, while it does not have a greated OD, it is much thicker. Examples:

oil based --- Finishing agents made with a drying oil (e.g. linseed, soya, or tung oil) as the vehicle and binder, and mineral spirits / paint thinner or naphtha as the thinner.

oilcloth --- Traditionally a heavy cotton or linen cloth, sometimes canvas, with a lindseed oil coating that made it semi-waterproof. It was used for tablecloth, kitchen shelf coverings, raincoats, tents and other applications where water repellence was important. Modern oilcloth uses synthetic coverings instead of lindseed oil.

oil stone --- A type of sharpening stone with which oil is used as both as a lubricant for the sharpening process and to create a slurry to carry off the swarf as the sharpening progresses. oil stones tend to be fine grit stones. Water can also be used with such stones for the same purpose.

oily --- a characteristic of certain woods which contain natural oils. This includes, but certainly is not limited to, cocobolo, olive wood, teak and others. There are two serious issues with these woods. First, they can be hard to glue. This problem can be ameliorated by wiping down the surfaces (to be glued) with acetone, which cuts the oil and allows better adhesion of the glue. The second is in finishing. The oil resists polyurethane in particular. This problem can be solved by putting on a base coat or two of dewaxed shellac (NOT regular shellac) to which other finishes will adhere with no problems.

Oland tool --- A homemade lathe tool designed by Knut Oland, with construction instructions available on the internet. it is a multitip scraper. It consists of a steel rod drilled out at the end to accept a machine lathe bit and with whatever kind of handle you choose to put on it (I've seen some with masking tape as the handle). It's inexpensive and fairly easy to make and by all reports makes an excellent turning tool and it has the advantage that you can replace the tip. Examples:

old growth forest --- An old forest that has never been altered or harvested by humans. There is no specific age requirement but most sources quote 200 years old as constituting old-growth. That is, a forest that has grown up over a period of 75 or 100 years on what was previously farmland, and that has never been altered by humans would still not be classified as old-growth because it is too young. An old-growth forest tends to have large individual trees, a multi-layered crown canopy, and a significant accumulation of coarse woody debris including snags and fallen logs, on the forest floor. Trees harvested from such old growth forests have narrower growth rings and are more dense than trees of their species that grow elsewhere because the heavy canopy promotes slow growth. Also, such trees tend to be relatively free from knots because the heavy canopy suppresses the growth of lower branches that are the cause of knots.

old growth --- Wood from an old growth forest

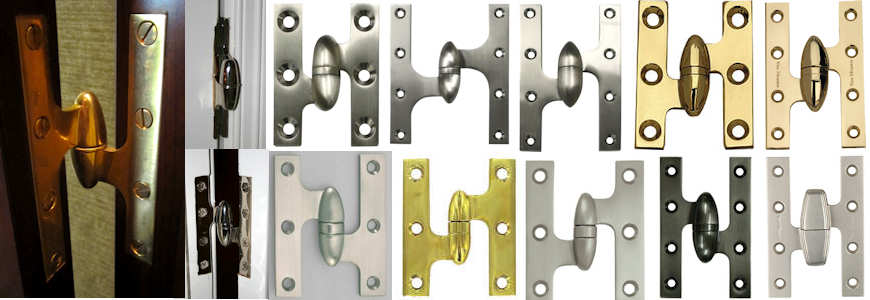

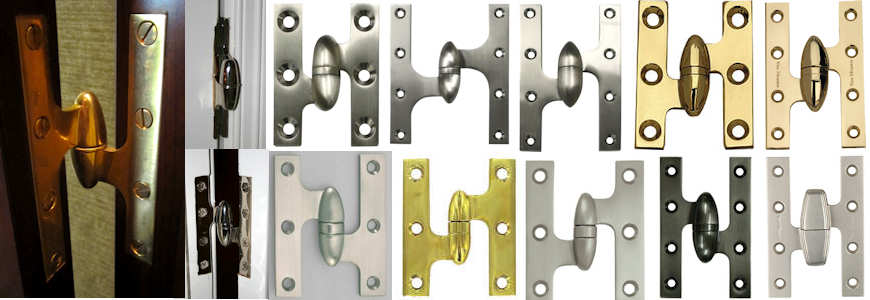

olive knuckle hinge --- A particular form of H hinge where there is a single knuckle on each (hinge) leaf and each is shaped like an acorn. Although the name derives from it being shaped like an olive, the shape is really more like a back-to-back pair of acorns, as you can see in the composite pic below. These are normally mortised into the edge of a door and into the frame and only the (hinge) barrel will be visible when the door is closed, and they are normally a form of ball bearing hinge. Examples:

on center --- [OC] Describes the spacing from the center of one structural member to the center of the adjacent member of the same type that is aligned in the same direction, as in the spacing of studs, joists, rafters, etc. Typically, the on center spacing of wall studs in home construction is 16" but it might also be 24"

one third lap --- synonymous with three way lap joint

onion burl --- A burl that grows as a wart-like protuberance on a tree just like a "normal" burl but which, unlike "normal" burls, has annual growth rings. Because this IS a burl, the growth rings frequently do not adhere well to each other and such burls can actually fall apart like the layers of an onion. Because of this adverse working characteristic, such burls are sometimes called the "dreaded onion burl" because they fall apart when turning them on a lathe (NOT a happy occurance, especially if they are spinning at high speed). You can't tell (as far as I know) an onion burl from a "normal" burl from the outside, you just have to SEE the growth rings.

opacity --- The extent to which a material does not pass light. As regards woodworking, this generally refers to the ability of a finishing agent to hide the surface to which it is applied. Compare/contrast to transparency.

opaque --- Describes material that completely blocks the passage of light and which therefore cannot be seen through even vaguely. Compare/contrast to translucent and transparent. Examples:

open coat --- Sandpaper is characterized in many ways, one of which is open coat / closed coat. Closed coat sandpaper has grit over 100% of the surface of the backing paper, which causes it to clog very readily with sawdust if it is used to sand wood. SO ... it usually isn't used to sand wood, it is more often used to sand metal. It might be used to sand hard finishes applied to wood and it might be used as a last, high-grit, sanding of a hardwood surface because it has less tendency to leave scratches than does open coat. Open coat sandpaper has grit that is more or less uniformly spread, but at the micro level, it only covers 40% to 60% of the area of the backing paper, thus leaving spaces for the sawdust to flow into and not clog things up. If you keep open coat sandpaper fully in contact with the surface the whole time you are sanding, it WILL clog up somewhat (but less than closed coat) but all you have to do is lift it a little every few strokes and the dust will fall out and get shoved aside on the next stroke. Also, you can smack open coat sandpaper against a hard surface to remove the dust. Open coat sandpaper is used almost exclusively to sand wood, not metal.

open defects --- Irregularities such as splits, open joints and knotholes that interrupt the smooth continuity of planks or veneer with some kind of open area.

open ended wrench --- A type of wrench that is a flat bar with two separated prongs on one or (usually) both ends that fit around the head of a bolt or around a nut to turn it. These come in both English and metric sizes and are sold both individually and in sets. Compare/contrast to crescent wrench. Examples:

open face --- the loose side in veneer

open form --- A wood turning item that has an opening larger than the base but significantly smaller than the maximum diameter. If the opening is really small, it's a hollow form. Compare/contrast to other lathe turnings. Examples:

open fret --- Fretwork that is an integral part of a workpiece; carved fretwork. Compare/contrast to blind fret.

open grained --- (1) Wood that has large open pores which are conspicuous in both the figure and the texture. In this definition, the term is synonymous with coarse textured although when discussing the finishing characteristics of a wood, the term "coarse textured" is more correct (when it is appropriate) than "open grained" since wood CAN have closed grain but still be coarse textured because all of its fibers are generally large. Compare/contrast with closed grain

open grained --- (2) [rarely used in this sense] Synonymous with loose grained. An excellent example of wood that has this characteristic is the fast-growing wood paulownia.

open knot --- synonymous with knot hole

open mortise and tenon --- synonymous with bridle joint

open pore --- A large, open-ended, pore such as would be found in, for example, red oak. See also open grained. Note that open pores pretty much imply coarse textured wood. Compare/contrast to closed pore. Example:

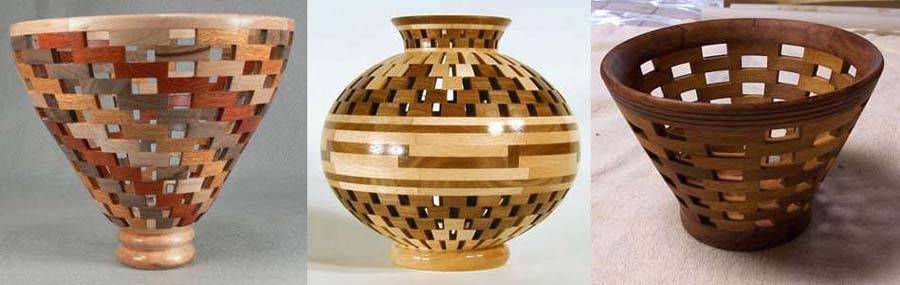

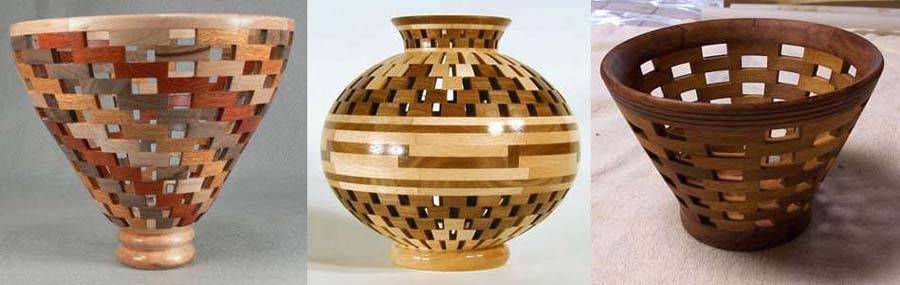

open segmented bowl --- A type of segmented bowl that has empty spaces among the pieces; generally these are regularly spaced but some designs have them distributed irregularly. Examples:

open side --- the loose side in veneer

open soffit --- A technically incorrect term that refers to what is more properly called an "open soffit area" and is only a "soffit area" in the sense that it is the area where the soffit would go if there WERE a soffit. see soffit for further discussion and related terms. Compare/contrast to closed soffit.

open staircase --- A staircase in which there are only treads and no risers, giving a very open look, unlike the more traditional closed staircase.

open time --- synonymous with working time

open valley --- Valley installation using sheet metal down the valley center, with no shingles. Compare/contrast to closed cut valley and woven valley.

orange peel --- Dimpled, bumpy, or wavy surface of a finishing agent (looks similar to the skin of an orange), usually caused by spraying in high heat, draft or through the application of a material that is too thick or heavy in viscosity resulting in poor leveling. A common defect in both spray and roll applied coatings. For some coating appliances, an orange peel effect may be desirable, but as a rule, it is not.

orbital sander --- A type of hand held power sander with an internal mechanism that converts the rotary motion of the motor into a vibrating pattern (often called "random orbital", with the sander being called a "random orbital sander") that prevents build up of the kind of scratch marks that can occur with a belt sander. Used for finish and detail sanding, there really are three types, one is the detail sander with a triangular pad and the others have either a rectangular or circular pad. Compare/contrast to other forms of power sander. Examples:

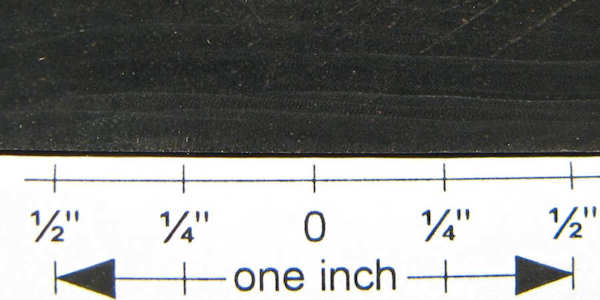

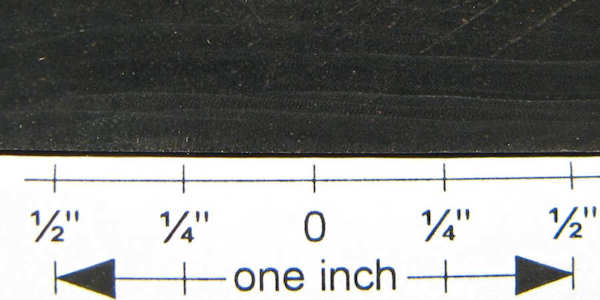

orbital sander scratches --- All sanding has the capability of leaving scratches on wood, but orbital sanders, when used in a way that leaves scratches at all, can leave an interesting pattern of scratch-marks that look like a slinky-toy stretched out. In the example below, I moved an orbital sander on several passes of straight (more or less) lines along the end grain of a very hard wood (African blackwood) and you can see the result where one of the grains in the sandpaper left several such series of scratches. The diagonal scratches are from an earlier sanding with a coarser-grit belt sander. Note the scale; you can't even see these marks without a magnifying glass.

order --- see taxonomy for a discussion

organic --- (1) Any item or chemical that is or was alive and contains carbon.

organic --- (2) Relating to, or derived from, or having properties characteristic of living organisms.

organic --- (3) Describes something that fits so well into its surroundings that it seems to just naturally belong there.

oriel --- synonymous with bay window, although a bay window on the first floor with a support structure that just continues the outline down to the ground is NOT an oriel.

oriented strand board --- Structural panels made of narrow strands of fiber that are oriented lengthwise and crosswise in layers and bound together with resin. Depending on the resin used, OSB can be suitable or interior or exterior applications. OSB, like plywood, is used in applications where strength and stiffness are required, e.g., Roofs, walls, floors, etc. In making OSB, logs are fed into a lathe-like machine where the bark is removed and the machine chews up the logs completely to produce flakes of wood. These flakes are sifted to eliminate the very tiny particles, then mixed thoroughly with a dust of waxes and heat-triggered resin glues. Layers of the flakes are placed in alternating directions until the desired thickness is achieved. Some definitions say the flakes are placed at right angles to each other but the OSB I've seen has all had what appears to be random placement. This is placed in a thermal press that activates and compresses the loose materials at the same time, causing the wax covered resin to activate and bond. Examples:

O ring --- [also O-ring] A gasket that is made of rubber in the form of a donut.

orthogonal --- A 3D Cartesian coordinate system having 3 mutually perpendicular axes; having a set of mutually perpendicular axes; meeting at right angles.

OSB --- oriented strand board

oscillating drum sander --- A type of drum sander where the drum is mounted vertically in a mechanism that causes it to move up and down slowly while rotating rapidly. This prevents sanding sleeve imperfections from causing "lines" in the workpiece. The sanding drums are those described with a similar drum sander, the drill press drum sander. Compare/contrast to other forms of power sander. Examples:

outboard --- see outboard turning

outboard bowl scraper --- See full discussion give with the term bowl scraper. Examples:

outboard turning --- Face turning which is carried out on an extension of the drive-shaft on the left-hand side of the headstock, ie the opposite side to the bed. Some lathes have headstocks that swivel around away from the bed, thus allowing outboard turning to be done using the same spindle as inboard turning, and some simply mount the faceplate or chuck on the opposite site of the headstock, away from the bed. In that case, then relative to the turner the workpiece will revolve in the opposite direction as compared with turning over the bed; as a consequence the drive spindle and attachments (e.g. chuck or faceplate) require reverse threads. Outboard turning in those cases where the workpiece goes in the opposite direction from normal requires tool use on the opposite side of the workpiece, and some tools (e.g. outboard bowl scraper) have special versions for that use. Other tools (e.g. bowl gouge are symmetrical and can be used for inboard or outboard turning. Compare/contrast to inboard turning.

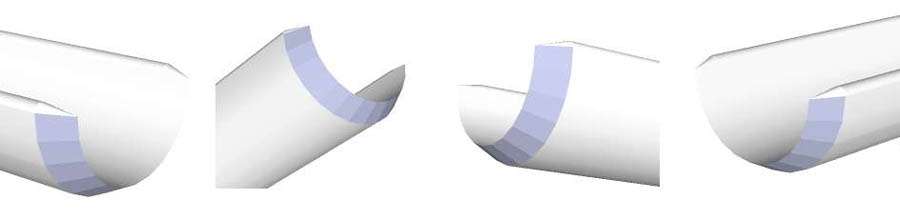

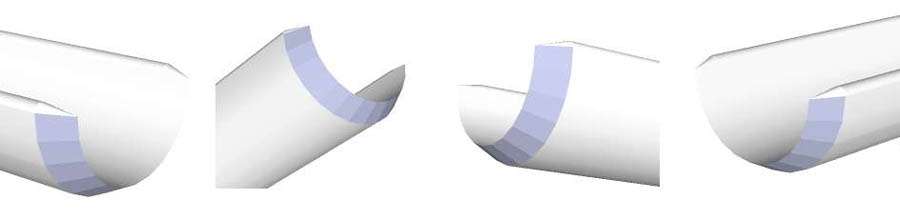

out-cannel --- The characteristic of a gouge that has its ground and sharpened end section on the outside of the blade. Out-cannel blades are used to carve or turn convex surfaces. Compare/contrast to in-cannel. Examples (actually these are all the same gouge drawing, just seen from different angles):

outer stringer --- see stair stringer

outfeed --- (1)[noun] the direction a workpiece is fed out of a blade or cutter

outfeed --- (2)[noun] The area into which a workpiece is fed out of a blade or cutter

outfeed --- (3)[verb] The process of feeding a workpiece out of a blade or cutter.

For all three, contrast to infeed.

outlined joint --- Any joint, but most particularly a box joint or through dado joint, where there is a layer of contrasting wood between the mating pieces so that the joint looks as though it has been outlined by a thick magic marker. This can provide a very pretty look but is a lot of work to accomplish neatly. Fancy versions include double outlines and conversion via outline from dovetail to/from box joint (these are called, appropriately enough, conversion joints). Also called a "boxed joint" (not to be confused with "box joint"). Examples:

oval skew chisel --- A skew chisel that has an oval cross section taken perpendicular to the length of the chisel. The point of having the oval sides is that this makes it easier to rotate the tool on the tool rest for variable slicing angles as it is moved over a variable workpiece surface. For an extreme example of this, see the round skew chisel Examples:

oven dried weight --- The weight of a piece of lumber that has been dried in an oven, generally at around 220 degrees fahrenheit (just over the boiling point of water at sea level), until it is devoid of all water. This weight is used in calculating the moisture content of wood and it is the basis for all moisture level discussion about wood. See the discussion with the term moisture content.

oven dry ton --- synonymous with bone dry ton

ovendry wood --- Wood dried in a ventilated oven until it has no more moisture. The weight of such wood, called The oven dried weight, is used in calculating the moisture content of wood.

over cut --- A wood carving term meaning to carve past the pattern lines.

overdriven --- Refers to fasteners driven into material with too much force, breaking or crushing the material under the head of the fastener. Compare/contrast to underdriven.

overhang --- The end of a beam that extends beyond its support (e.g. the eaves of a house, where the rafters extend past the side of the house).

overlay door --- see face frame door

overlay face frame door --- see face frame door

overrun --- The situation where a mill expects to achieve a certain number of board feet from a run but obtains more than expected. Compare/contrast to underrun.

oxidation --- The result of the process of oxidization; a layer of oxidized material on a surface.

oxidization --- A layer of metal oxide formed by the chemical reaction of oxygen with a surface; rust is one form of oxidization.

oxidize --- To react chemically with oxygen (generally from the air). Rusting is a slow form of oxidization, fire is a more rapid form.

oyster veneering --- A very specialized type of "veneering" construction that was introduced in the late 17th century in England and used initially in what we now call "William and Mary" style furnishings. I put veneer in quotes in that first sentence, because this isn't really what one normally thinks of as veneer sheets, it is a parquetry technique. It is called "oyster" because the construction technique makes use of tree branches sliced at an angle to their axis (sometimes 90 degrees resulting in a cookie and sometimes a more shallow angle, resulting in a plaque) and done with a strong-grained wood so that the resulting grain pattern resembles the concentric ovals found on an oyster shell. What you do is take a high-grained tree such as black walnut or olive, and you select a branch of perhaps 3 inches diameter and slice it at anything from 90 degrees down to as little as 30 degrees , cutting off a thick "veneer" slice of about 1/8" thickness and you do this all along the branch so that you end up with many cookies of high-grained wood. You then lay these down all around each other, perhaps slicing the sides flat so that they fit well together, or you could cut them into rectangles or hexagons, again so that they fit well together. If there are spaces left in between, these can be filled with similar slicings from smaller branches. In some versions, all of the "veneer" is built up this way from various sized branches. When done with larger branches, this produces a fairly large-pattern result with a nicely geometric design. When done more randomly with lots and lots of smaller branches, particularly if you choose branches with some color variation, it produces a really wild and dramatic look. This is a very labor intensive process and was only used for high-end furniture. I imagine this must be an antique-restorer's nightmare. Below are some examples. On the left is a dresser front with an oyster veneer panel made from small branches and just to the right of that at the top is a closeup of one area. The others show various patterns, including one with a fancy inlay in addition to the oyster veneering, and then a dresser with large-branch oyster veneered panels.

for images of wood itself, go here: wood id site

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY