| 80 | balsa wood |

| 300 => 400 | soft cedars and pines, paulownia, some poplars and cottonwoods easily dented with a fingernail |

| 1100 => 1300 | various oaks |

| ~2000 | mesquite, purpleheart, hickory |

| ~3000 | various ebonies |

| 4500 | lignum vitae - you can drive nails with this stuff ! |

| ~5000 | Australian bull oak |

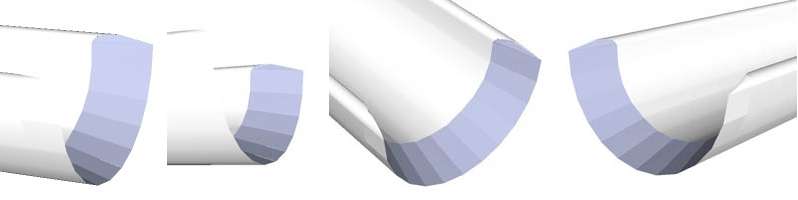

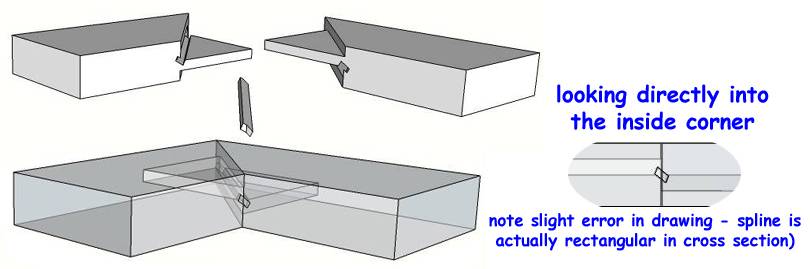

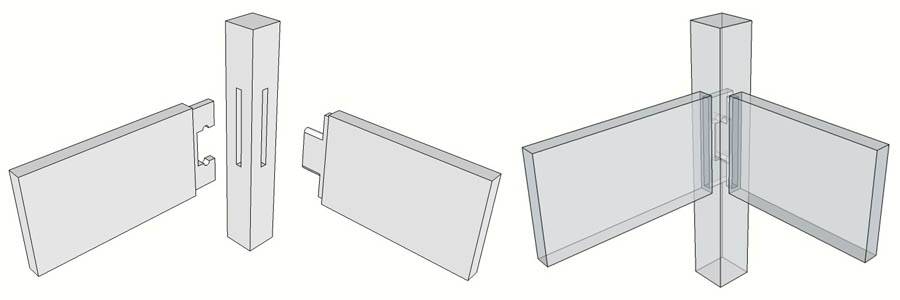

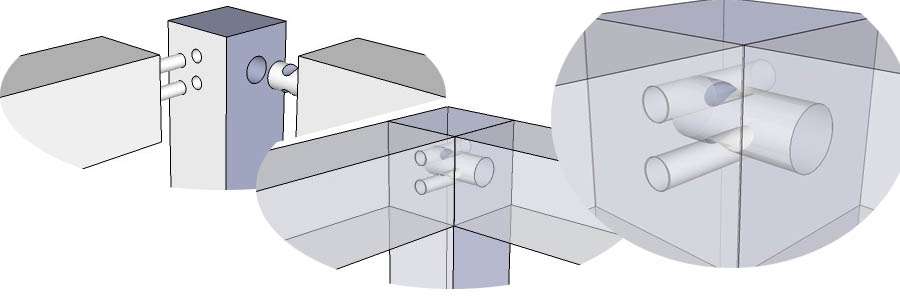

need to add joinery chisel pics

need to add joinery chisel pics