The HobbitHouse Ilustrated Glossary of Woodworking terms

A

B

C

DE

F

GH

IJK

L

M

NO

P

QR

S

T

UVWXYZ

To see general comments about this glossary and for the email address, click here: GLOSSARY

for images of wood itself, go here: wood id site

CA --- see superglue

cabinet --- A box-shaped form, frequently fairly large, either standing alone as a piece of furniture (e.g. "stereo cabinet", "television cabinet", "display cabinet", break-front) or built into or attached to a wall (e.g. "medicine cabinet", "kitchen cabinet") and used as storage for either a single object such as an electronic device (e.g. stereo set, TV, audio speakers) or a storage for a loosely related set of objects (e.g. medicines, plates and glasses, decorative objects). Cabinets normally have shelves and they may or may not have drawers as well. The making of fine quality wooden cabinets is so much a part of the art and craft of woodworking that it has its own name, cabinetry.

cabinet connecting screw --- synonymous with confirmat screw

cabinet maker --- A skilled craftsman who specializes in making fine furniture including, but not limited to, cabinets. See also cabinetry. Compare/contrast to carpenter.

cabinetry --- The craft of making furniture (especially furniture of high quality including, but not limited to, cabinets) utilizing various woodworking skills including joinery. See also cabinet maker.

cabinet saw --- This is the top of the line in table saws and is generally more saw than a hobbyist needs. It has an enclosed steel cabinet (thus the name) below the table to house the motor and trunnion and the trunnion is attached to the cabinet (instead of the table as it is in a contractor saw) which makes for better and more solid alignment. The motor is not in line with the blade's arbor as it is in a contractor saw but rather is attached to the arbor by a hefty belt. Also the trunnion on a cabinet saw is typically more heavy duty than on a contractor saw and the table is heavy cast iron. The weight of this tool can be a real problem for a hobbyist when assembling it. Moving it, once it is all put together, is pretty much out of the question. The good news about the weight is that it runs more quietly than a contractor saw and is essentially vibration-free. It runs off of 220 volts and thus is more powerful (3HP and up) than other table saws, but of course that has the disadvantage of not being standard house power, which can be a problem for the hobbyist. The table is generally quite large and may include a large outfeed table. Most models have a mounting area for a router near where the saw blade sits so that the same table can double as a router table. Compare/contrast to contractor saw, hybrid table saw and bench top table saw. Examples:

cabinet scraper --- A thin, flat, piece of steel that has a straight or gently curved lower edge which is burnished to a fine, sharp edge and used to remove very slight amounts off of the surface of a piece of wood at the end of a process of surfacing the piece. The scraper is drawn along the surface with the sharp edge at a slight angle off of a perpendicular against the surface and it literally scrapes off a fine layer, but does so in a smooth, controlled way that leaves a smooth finish, not the roughness that one would normally think of in the normal English language sense of the word "scrape". The burnishing of the tool can leave a fine burr which on other tools would usually be honed off before use but which on a cabinet scraper is often left on and made use of in the first few strokes, which both use its cutting power and also remove it at the same time.

There are three fairly standard shapes for cabinet scrapers. The first is a rectangle, the second is a rectangular shape with a concave curve on one end and a convex curve on the other end,and the third is a French curve shape (sometimes called a "gooseneck" cabinet scraper). See also cabinet scraper burnishing tool for an illustration of how this tool is "sharpened". Examples:

cabinet scraper burnishing tool --- a metal rod with a handle on one end; looks like a screwdriver with just a plain end (some people USE a screwdriver for this tool). The cabinet scraper is put into a vise and the burnishing tool is pushed down onto its edge at a slight angle and moved along the edge to create a rolled over part that is the scraping edge of the scraper. The illustration below not only shows several such tools, but on the far left shows one in use and just to the right of that shows the kind of edge that is created:

cable clamp --- see pipe clamp (type 2)

cabriole leg --- A furniture leg style that is somewhat similar in shape to an animal's leg. Because of the multiple curvatures involved, making them is considered quite a challenge for woodworkers. The style goes back to ancient Greece and China, but in our wonderfully insular way, we in the Western world consider it to be something that was invented in the 1700's as part of what is known as the "Queen Anne" style of furniture. On English and French furniture from the 1700's they are often carved with very elaborate and intricate designs but on more modern furniture (the shape is still widely used) they are more likely to be unadorned. Because of the animal-leg shape, the more elaborate ones are sometimes finished at the bottom with a carving of claws holding a ball (see claw and ball). Here are a few images of cabriole legs:

calibrate --- To cause something to undergo calibration.

calibrated --- Having undergone calibration.

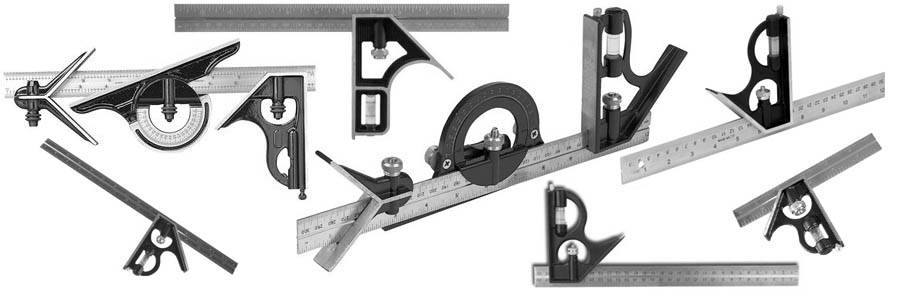

calibration --- (1) The process of establishing an accurate relationship between a measuring device and the units it purports to measure, by virtue of comparing the reading of the device with a standard of known high accuracy, and adjusting the device to be within some given tolerance of closeness to the standard. For example, clocks can be measured against the "world clock" kept by the US Naval Observatory, that has some amazing degree of accuracy. Normal clocks don't come close to the accuracy of the world clock but using it as a standard, you can determine that a more normal close looses, say one second a day or one second a month, or whatever.

calibration --- (2) Affixing units of measurement to a measuring device. This actually should be called "graduating" or "graduation", not calibration, but the usage is apparently so common that I give it here even though I don't think it should be used.

calipers --- A measuring tool used for either (1) making more accurate measurements than are possible with the relatively gross markings on a normal ruler or yardstick [vernier calipers] or (2) taking measurements that cannot be readily done with a ruler or yardstick (e.g. the diameter of a portion of a spindle or the wall thickness of a turned bowl) [transfer calipers]. There are several flavors and each has its own entry in this glossary. The gross level designations are based on the measurement technique (either transfer or some variation of direct vernier scale) but there is another characteristic of calipers and that is whether they are designed for inside or outside measurements. All of the gross types listed below come in both inside and outside forms and except for transfer calipers, which tend to be one or the other, most do both measurements with the same instrument.

calorie --- The amount of heat energy required to raise the temperature of 1 gram of pure water 1 degree celcius; equivalent to 3,968 BTUs)

cam --- A flat object with a circumference in the general shape of an involute curve, used in various mechanical constructs to use mechanical advantage to change the direction of a force and/or to provide a clamping action. Often used to change rotational motion to a back-and-forth linear motion or the other way round (as is the case in automobiles). The simplest form of cam is a simple (circular) disk that is mounted on an offset center so that when it rotates, the distance from the center of rotation to a point at the edge changes, as in the sample drawing below This converts the circular motion of rotating the disk into a linear motion that can be used in clamps and other devices. Example:

camber --- As regards woodworking, this refers to curvature built into a beam in a direction opposite to the extended deflection to prevent it from appearing to distort under a loaded condition. Most commonly, this is an upward curve in a beam that will have a load pressing it down and the camber makes the beam, under full load, horizontally straight rather than sagging downward in the middle. This is mostly for appearance but does have the structural advantage of providing stronger support, providing that the corresponding outward pressure at the ends of the beam is properly accommodated.

cambium --- The growing part of a tree, just under the bark at the outside of the sapwood. It is the cambium that forms new sapwood (on its inner side) and new bark (on its outer side) each year. It was long believed that the cambium was only one cell thick, and you will see it so described in older books. It is now recognized that the cambium is several cells thick during the growing season and one cell thick in the winter. It repeatedly divides itself during the growth season of a tree to form new wood in the fundamental process described briefly in this glossary with the term tree growth.

cam clamp --- A clamp that uses a cam to exert pressure. Cam clamps have a limited range and may come loose if there is vibration around them, but they are a quick-and-simple mechanism that can be very useful in woodworking operations. Typically, the cam is mounted on a shaft that goes into a bench dog hole in a benchtop and it provides a force parallel to the benchtop.

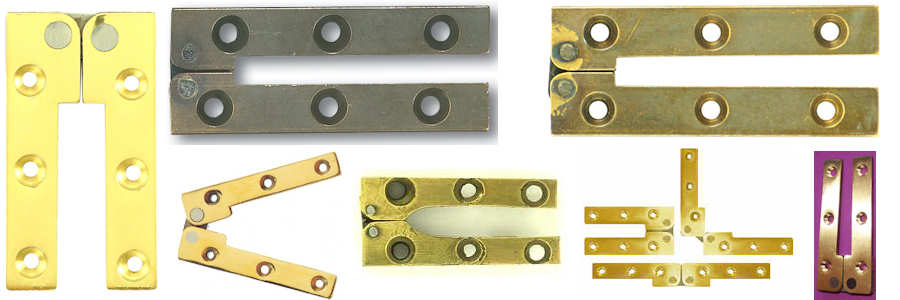

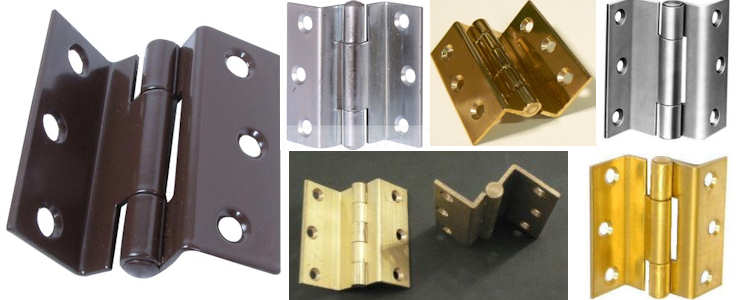

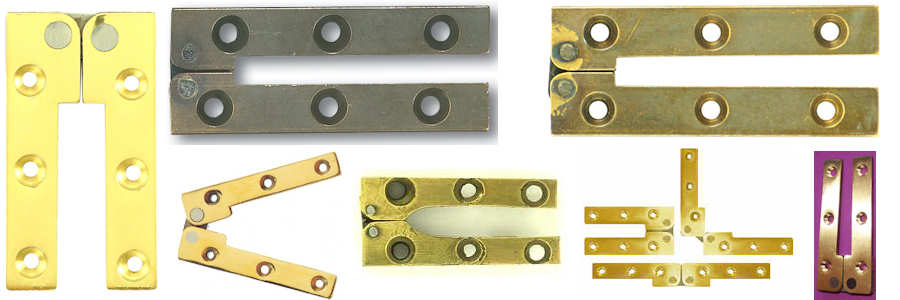

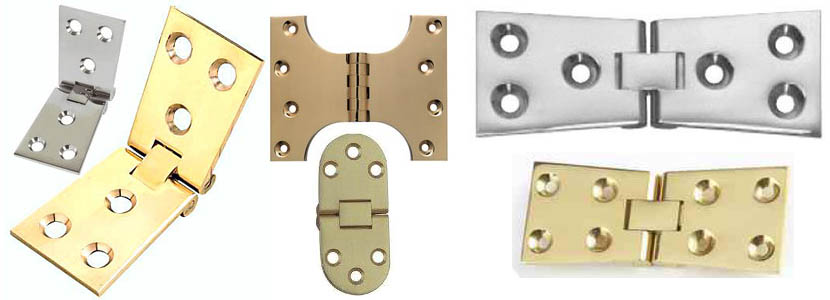

cam lift hinge --- There are at least two types of cam lift hinge. The first is a type of butt hinge where there is a slant to the mating edges of the barrels on the door plate and the butt plate such that when the door is opened, the hinge mechanism causes it to rise, thus creating a lift against gravity that will then cause the door to close by itself when released. In addition to working as a door closer, this type of hinge also allows the bottom of a cabinet door to be right down at the carpet level because while a normal hinge in that situation would have the door scraping across the carpet as it opened, this hinge lifts the door up off of the carpet as it opens. One more advantage to this hinge is that it is a type of lift off hinge. The second type has the cam lift action but is not a lift off hinge and is more like a T hinge than a butt hinge. The second type is not shown in the composite pic below. Examples:

cannel --- The hollowed out part of a gouge blade. The ground, sharpened end of the cannel is the cutting edge of the gouge. If the ground out portion is on the inside of the blade it is called in-cannel and if it is on the outside of the blade, it is called out-cannel. As a nominal rule, In-cannel blades are used for concave surfaces and in-cannel blades are used for convex surfaces but good wood turners make their own rules after experimenting with what works best for them.

canopy --- (1) A layer of foliage in a forest stand; usually refers to the top layer of foliage, but it can describe lower layers of multi-storied stands. The canopy of a densely packed grouping of trees grows close together and provides shade at ground level.

canopy --- (2) An architectural term with somewhat varying meanings, but generally referring to a projection that provides weather protection, or even just decoration.

cant --- [noun] What remains after a felled tree has been debarked, delimbed, and then had the rounded slab or outside portion of the log cut off by the sawyer. The remaining square or rectangular portion of the log is called a cant and is used for the further production of lumber by resawing. usually at right angles to the widest sawn face. The term is loosely used and sometime also refers to logs that have only had one or two curved sides removed. Also see flitch.

cant --- [verb] to tilt or heel over, as in "to cant the blade to one side".

cant dog --- synonymous with cant hook

canted --- [adj] Angled, leaning

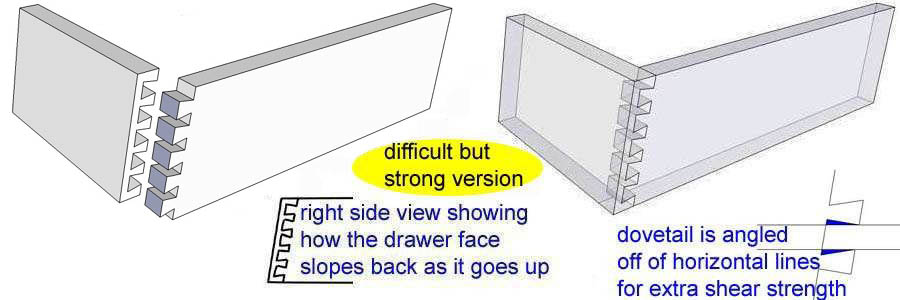

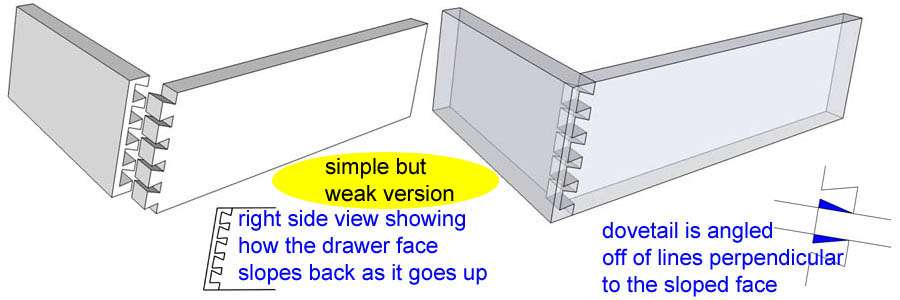

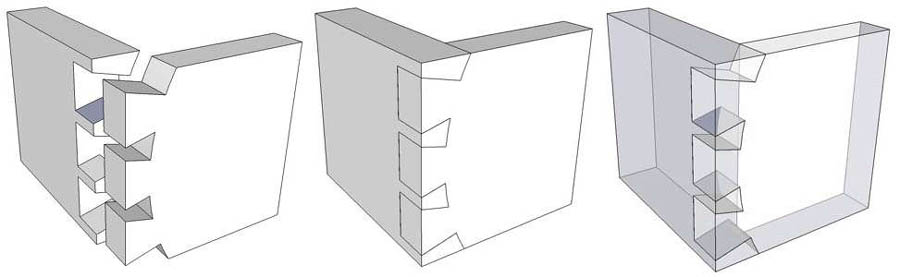

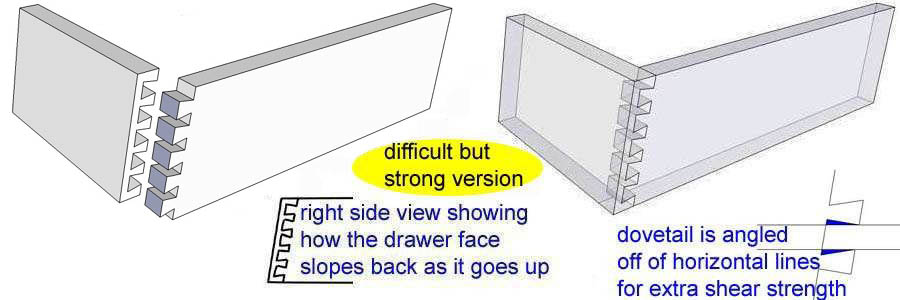

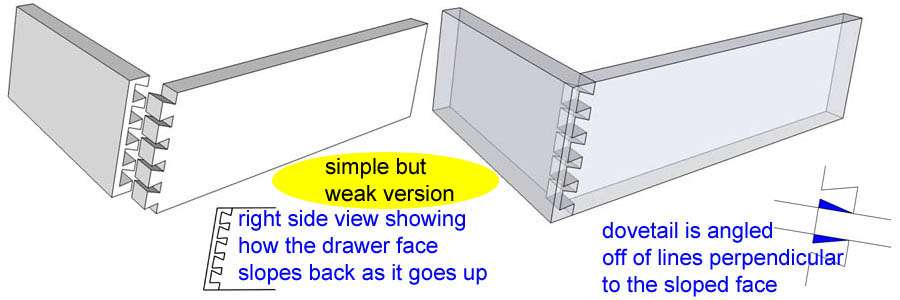

canted half blind dovetail --- When a drawer front is tilted (canted) backwards a little, as is the case in (for example) dressers that are wider at the bottom than at the top, some care needs to be taken in doing dovetails at the corners of the drawers, if dovetails are the joint of choice for the particular application. The problem is that if you make the dovetails based on the slanted edge of the drawer side, they will be easy to make with a standard jig, but they will be mechanically weaker than if you tilt them over a little. The reason for this is that in the "easy but weak" version the grain runs close, or even exactly, parallel to the lower surface of where the tail and pin meet, which means that the joinery adds no strength at that point, and the upper part of the tail/pin area presents an easy shear. Thus, the side could pull out, leaving behind the sheared off upper portion of each tail, with the lower portions of each tail having simply slid out. In the "difficult but strong" version, the upper portion of each tail could still shear off but it's not as likely because the lower portion exerts pressure that keeps the side from pulling out even if the glue fails, plus of course the lower area has joinery strength in addition to the glue. Examples:

cant hook --- A lumberman's lever with a blunt end and a hinged hook near the end used for rolling cants or logs. Exactly like a peavey except that it does not have the peavey's pointed tip. A sometimes more useful version of this is the footed cant hook which has a "foot" that keeps the log off the ground after it is rolled so you can cut the log with a chain saw but keep the saw blade from digging into the ground. You can even buy a foot to attach to an existing cant hook. Examples (the footed cant hook shown with a log on it is a double-footed version):

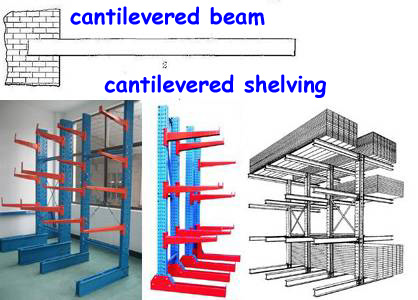

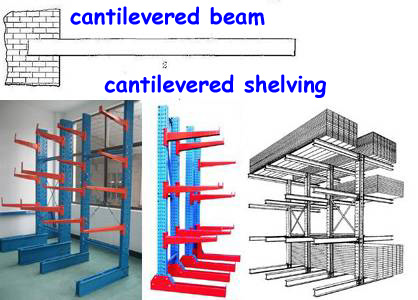

cantilever --- A horizontal projection from a building, such as a balcony, beam, or canopy, that is without external bracing or support of any kind, other than its own rigidity. Here's a really interesting example of a cantilevered construction --- it's a lap pool extending out from one side of a house:

cantilevered --- extended out beyond any support. A good example of cantilevering is the way some shelving is built. Cantilivering allows an unobstructed area at the insertion point of whatever is being shelved, such as planking, and also is a common construction method for beams that extend out over the front of store to hang signs on (many such have bracing on the upper part, but with no bracing they are cantilevered). See also cantilever. Examples:

canvas --- A very heavy, strong, closely woven but rough fabric that is used for strap clamps and many other things where fabric is needed and strength is more important than smoothness.

cap nut --- A hex head nut topped by a solid dome or a cylinder then a dome or even just a cylinder. These are usually all metal but occasionally all nylon. Such nuts can only be used with carefully measured bolts because the bolt has to grip into the nut securely, but it cannot protrude so far that the cap nut is raised above the surface being clamped. The purpose is to provide a decorative/safety type of topping that both looks better than a raw bolt end protruding through the nut, and which also prevents the bolt-end from scratching any nearby moving surfaces such as human knuckles. Automobile lug nuts are usually cap nuts but unlike "normal" cap nuts (as shown here) they have a tapered bottom. There is a more decorative version called the acorn nut and there is a version that more widely distributes the pressure on the clampled surface called the flanged cap nut. Examples:

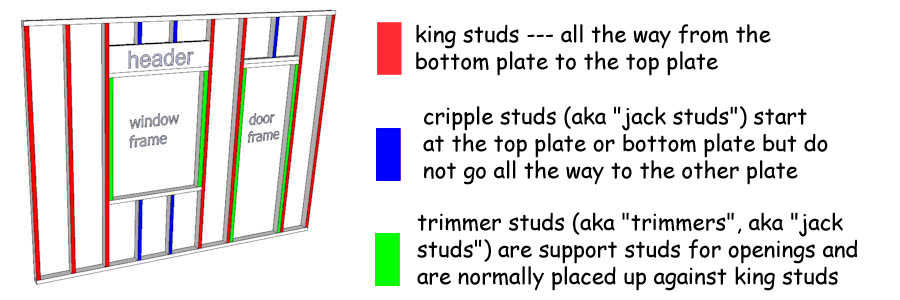

cap plate --- synonymous with top plate

cap screw --- A somewhat ill-defined term, sometimes also called a "hex cap screw" if it has a hexagonal head, this is a fastening device that is, by a limited definition, visually indistinguishable from a hex head bolt but which is manufacturered to tighter tolerances that are much more likely to be of interest in machining situations where high precision is necessary, as opposed to in woodworking where a normal (and less expensive) hex head bolt is going to do the job just fine. Such hex head cap screws are a tiny bit smaller in diameter than the equivalent sized hex head bolt and are threaded all the way along the shank. A looser definition maintains the requirement for high tolerance manufacturing but allows a wider range of body shapes. The name "cap" screw seems to be based on the fact that such a device always has a head (the "cap") that clamps against the material being fastened when the device is driven all the way in. Some definitions of cap screw state that they are a form of head bolt, meaning that they are not used with a nut.

captive hollowing tool --- An elaborate, articulate-arm, mechanism for doing precision lathe turning of deep hollow forms. Most (possibly all these days) come with an attachment that puts a laser beam on the outside of the turning form so that the wall thickness can be judged with great accuracy, thus allowing very uniform wall turning with no danger of making it too thin. These are expensive systems, but for those who do this kind of turning, I can see how they would be invaluable. Examples:

captive piece --- When two pieces of wood are joined with a screw, the screw goes through one piece, which is called the "captive piece" and into the other, which is called the "anchor piece".

captive ring tool --- A lathe tool; A special scraper that is used to cut full, self-contained rings on spindles such that they are captive around the spindle and look like they had to have been put there by magic. The "captive ring tool" is not at all the same beast as the ring tool. Captive ring tools come in two forms, the first being a solid ground scraper and the second being a variation of the multi tip scraper. Examples:

captive washer lock nut --- see lock nut

carbide --- A hard, sharp carbon/iron material that can keep a sharp edge for a long time when working against wood. In woodworking it is used mostly in tool tips, such as the tips on a circular saw blade and the cutting edges on router bits. It is particularly good in resisting the kind of dulling that comes with high speed use where the high temperature created in the metal can cause a lesser material to loose its temper

carbide tip --- A piece of sharpened steel of a particularly tough formulation that is brazed to the ends or edges of cutting tools such as circular saw blades and router bits to provide long-lasting sharpness and durable performance. Example of an inexpensive 10", 24-tooth circular saw rip blade with carbide tips:

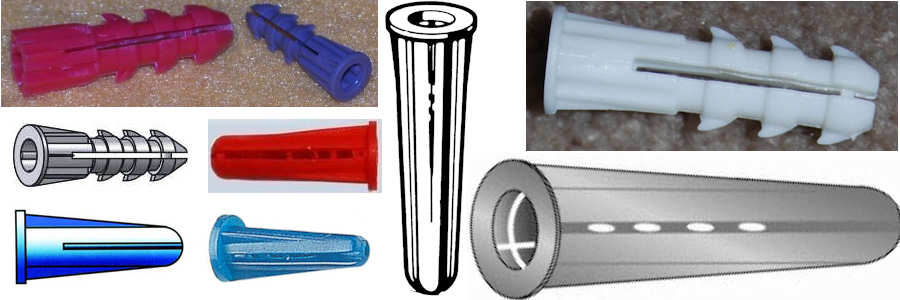

carbide tip drill bit --- A twist drill bit with a carbide tip, which is specifically designed for drilling masonry. The tip is wider than the shank thus providing room for the masonry chips/powder. Examples:

carbon steel --- A type of steel that, as far as woodworking is concerned, is generally an inferior grade for tools with cutting edges that move meet the wood at high speeds, such as lathe chisels and router bits. A better grade is high speed steel and even better is carbide tipped (see carbide tip). Carbon steel DOES have the advantage that it can be brought to a slightly keener edge than can high speed steel, but it does not keep that edge for long and needs frequent resharpening. When I am doing a turning where the end grain starts getting crushed instead of sliced, I will often resort to a carbon steel lath tool, freshly sharpened, to solve the problem.

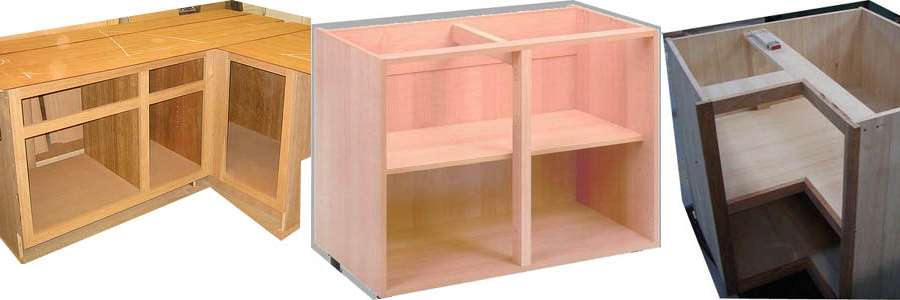

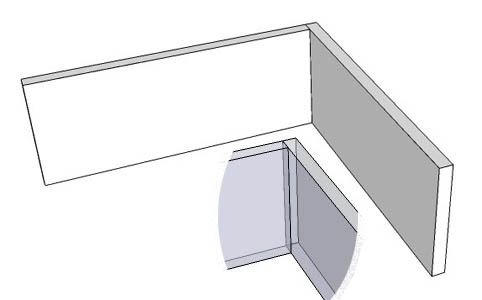

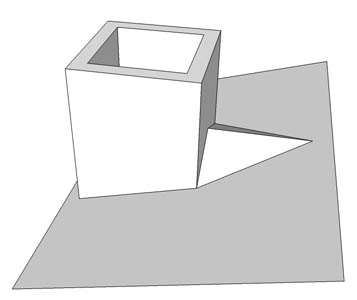

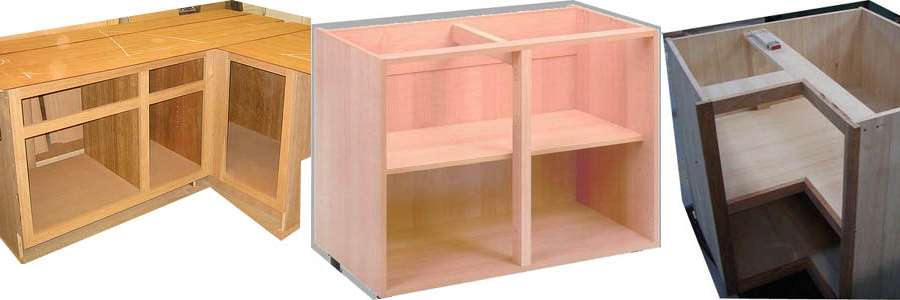

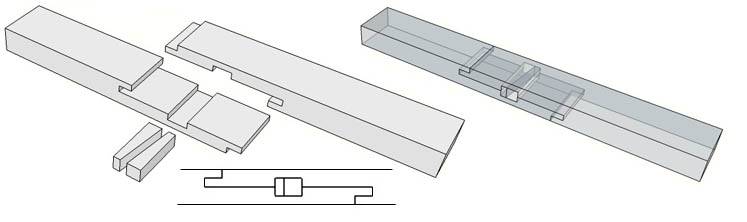

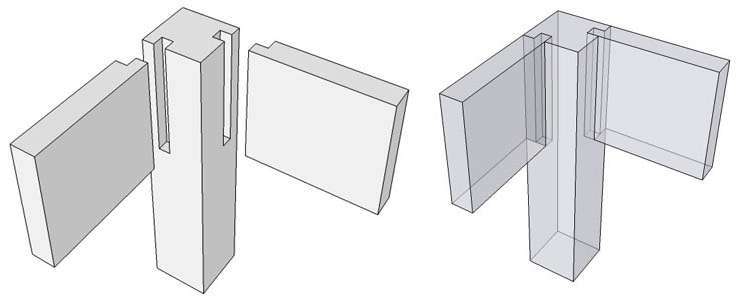

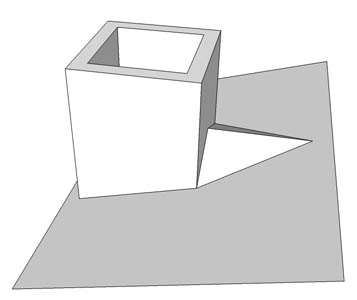

carcass --- The case or box of a piece of furniture. It is the rough framework and structure of the item into and onto which the cabinetmaker will eventually put a a top, drawers, edging and so forth. Often the front of a carcass will be covered by a face frame to hide raw plywood edges and to give extra support to doors. Carcasses include drawers, cabinets, bookcases, and so forth. The art of constructing joints for carcassses is called carcass joinery, and this is one of the two main categories of joinery, the other being frame joinery. Examples:

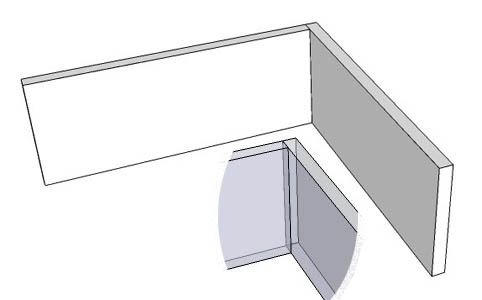

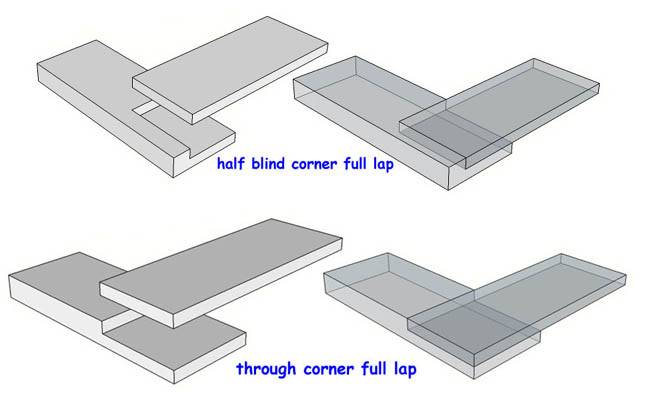

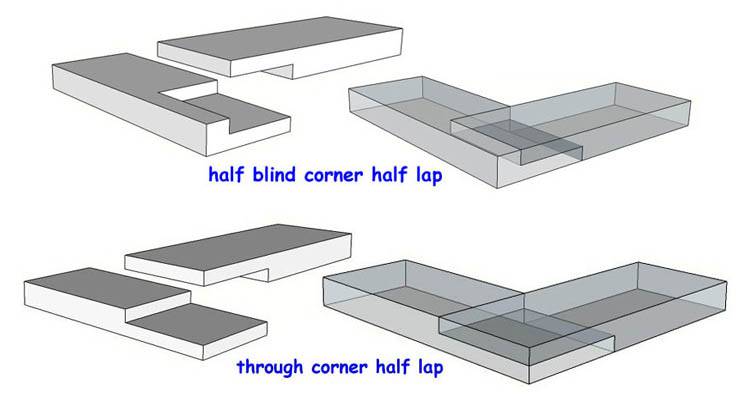

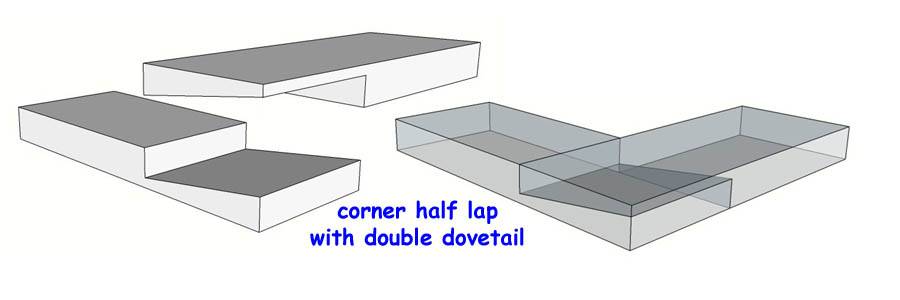

carcass joinery --- There are two fundamental types of joinery, carcass joinery and frame joinery. Carcass joinery is the art/science of attaching planes (of either solid wood or plywood) to form boxes. This is used for such diverse items as drawers, cabinets, bookcases, etc. Most joint types can be used for both frames and cases, but the types that are associated mostly with cases include dovetail joints, dado joints, rabbet joints, and box joints. Also called "case" joinery.

carcass joint --- A carcass joint is any joint used in the construction of a carcass (as opposed to a frame). See carcass joinery.

card --- [noun] An instrument used to part, comb out and set in order fibers of wool and hemp; basically a whole lot of stiff iron wires set in a frame. There is a version of this tool, called a file card that is used to clean files.

card --- [verb] To comb out fibers using the kind of implement described in the noun definition above.

cardboard --- A generic, non-specific term for any heavy duty paper based product. Some such constructions are called by other names as well, such as "construction paper", "corrugated fiberboard", etc.

card scraper --- synonymous with cabinet scraper

card table hinge --- A specialty hinge designed to allow parts of a card table top to fold up on itself. This is a style that was more in use in the past than it is presently. It is slightly similar to the scissorhinge except that there is no pin but rather a floating plate that rotates freely at both ends inside the two halves of the "scissor" plates. The point of this mechanism is to allow the parts of the table top to rotate from being along the same plane to being flat up against each other and to do so without there being any difficulty in the edges clearing each other; it does this by having the edges move away from each other as the flap part is rotated over on top of the rest of the table which would not be possible if there were a single-pin pivot point that was in-line with the plates, and you definitely wouldn't want a (hinge) barrel sticking up out of the surface of the card table. The part that contains the (hinge) pins is thicker than the rest of the (hinge) leaves so the mortise that is requred for these has two different depths. These are functionally quite similar to counterflap hinges. Examples:

carpenter --- A skilled craftsman who performs a wide range of woodworking that includes constucting buildings and other large wooden objects. The work generally involves significant manual labor and work outdoors, particularly in rough carpentry. In olden days a ship's carpenter was both what is now called a carpenter but was also usually a cabinetmaker as well. Compare/contrast to cabinetmaker and joiner. A person who is a carpenter COULD also be either of those as well, but would not necessarily be.

carpenter's pencil --- Octagonal- or oval-shaped shaped pencil, about 1/2" wide by 1/4" thick designed for use in the construction industry for marking structural members. Examples:

carpenter's ruler --- synonymous with folding ruler

carpenter's square --- synonymous with steel square

carpentry --- The work performed by a carpenter. Compare/contrast to cabinetry.

carpet tape --- There are numerous forms of tape used in various ways with regard to carpeting, but in terms of woodworking, this term normally is used to refer to a strong double-sided tape that can be used in various ways to hold wooden workpieces in place, usually temporarily, while they are being worked on.

carriage --- (1) The sawmill device on which a log is placed so as to move back and forth through the saw blade creating cants and lumber. The cant is sometimes turned on the carriage before making the next cut. In a circular sawmill, the cant can only be cut when passing in one direction but in a band sawmill it can be cut in both passes of the carriage back and forth. In a through and through cut, the carriage only has to make one pass with the log.

carriage --- (2) Synonymous with stair stringer

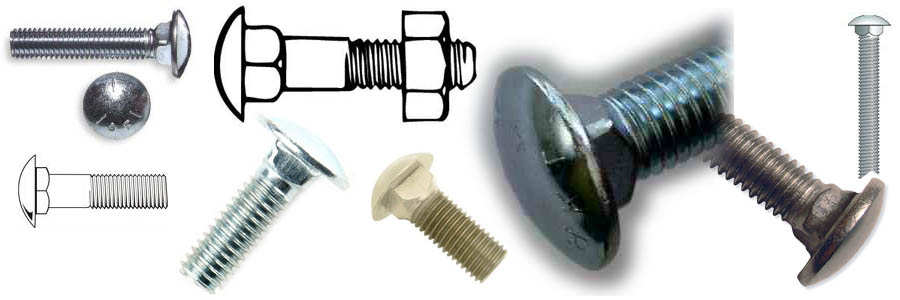

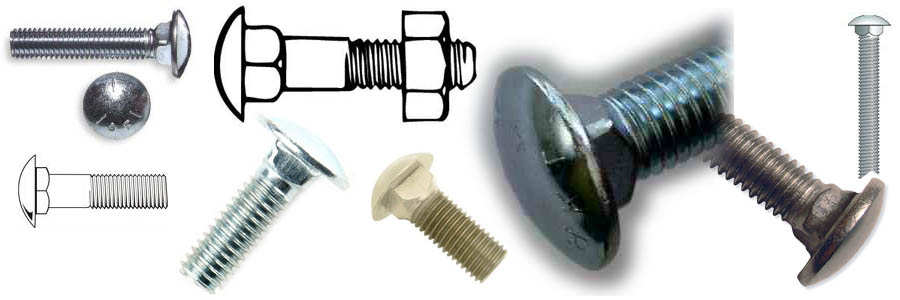

carriage bolt --- Also called a "coach bolt", this is a bolt with a square shoulder at the top and usually a rounded head with no screw-driver slot or other means for holding the head. This type of bolt is intended to be inserted into a cavity (normally in metal) that is square at the top and then a nut is put on at the other end and tightened with a wrench. The square shoulder in the square cavity keeps the top of the bolt from turning. There is another version that uses a ribbed section instead of the square section and this one is known as, and is illustrated at, ribbed neck carriage bolt. Examples:

carver's screw --- A type of clamp used by wood carvers; it consists of a threaded metal rod that is put through a hole in a workbench and screwed into the bottom of the item being carved. There is a nut or other tightening mechanism that goes under the bench. The traditional version has a wing-shaped metal plate with a square hole in it that fits a square head on the bottom of the rod for tightening the screw into the workpiece, and then that same plate acts as a tightening nut under the bench, thus removing the need for any other tool to do the carver's clamping. The beauty of the carver's clamp is that it leave all of the surface of the item being carved, except the very bottom, open to the carver. One possible drawback is that if a chisel is pressed or hammered into the edge of a workpiece in a way that imparts rotational force in the direction that tends to loosen the carver's screw, then occasional re-tightening may be required, which can be a pain. Examples:

carving chisel --- A chisel used for carving wood. Like the term lathe chisels, "carving chisel" is often used to include gouges. Carving chisels are often shorter than joinery chisels and lathe chisels because they are normally pushed by hand, although they may also be worked with a carving mallet.

carving gouge --- A sharp, curved-edge cutting tool made for wood carving. These gouges come in a wide variety of shapes and sizes. Although the length of carving gouges does not vary nearly as much as it does for lathe gouges, the size and shape of the blades varies much more widely, from shallow curves to a very tight arc and from very small blade tips to wide ones. The point of a carving gouge is to provide good control up close to the object being carved so that fine details can be accurately created, and to maintain a sharp edge so as to slice the wood rather than crushing it.

carving mallet --- A broad term for any number of styles of mallet, made of wood, rubber, or brass, and with numerous different shapes, all used to strike the rear end of the handle of a carving chisel or carving gouge so as to drive the sharp end into the wood. Lignum vitae is a favored wood for carving mallets because of its weight and toughness. Here are a number of examples of some of the most common styles and materials:

case --- synonymous with carcass

case hardening --- A term applied to dry lumber that has residual compressive stresses in the area of the outer zone of the tree and/or tensile stresses in the inner, core area of the tree. This typically occurs as a drying defect but can also occur due to reaction wood. In any case, it can be very dangerous because it can cause planks to unexpectedly bind on a power saw blade during ripping because once the blade cuts a kerf, the open kerf area will close in, due to the case hardening, as shown in the drawing below. The test for case hardening is to cut a slot in the wood (with a bandsaw for safety's sake) and see if it closes in.

casein glue --- An adhesive, primarily for interior use, prepared from casein, sodium silicate, lime, soda and other compounds. It is used largely in plywood manufacturer and tends to hold up well over time. Although it is not waterproof, it does have some moisture resistance and it can be formulated to be resistant to mold as well. Also sometimes used as synonymous with carcass.

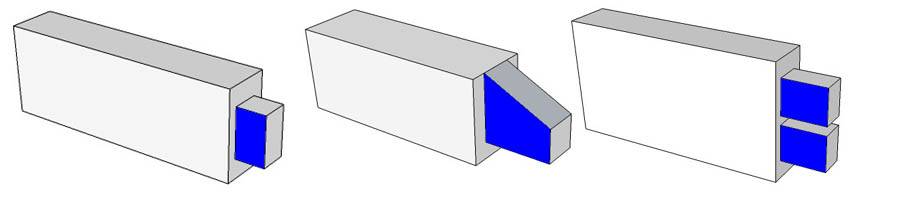

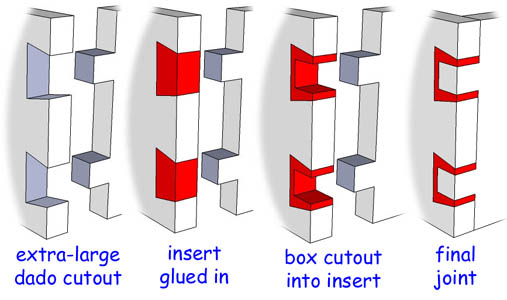

case joint --- In general, "case joint" is synonymous with carcass joint but there is one carcass joint that is sometimes specifically called the case joint and that is the simplest type of joint for a drawer front/side; the joint just butts the end of one plank (the drawer side) up against the face of the mating plank (the drawer front). The joint can be just glued, or it could be reinforced with biscuits or dowels. With no reinforcement it is a very weak joint. Compare/contrast to drawer locking joint and end miter joint. The case joint is also called an "end to face butt joint". Examples:

casement --- see casement window

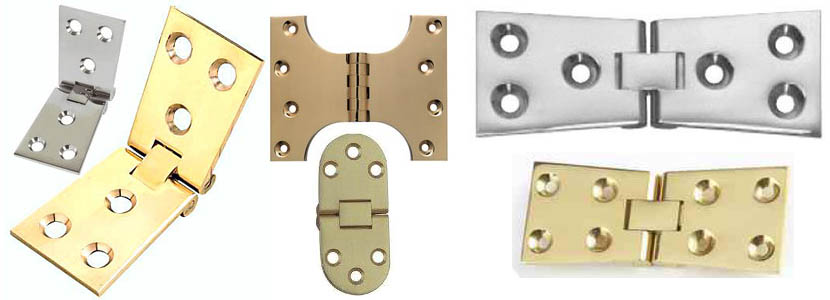

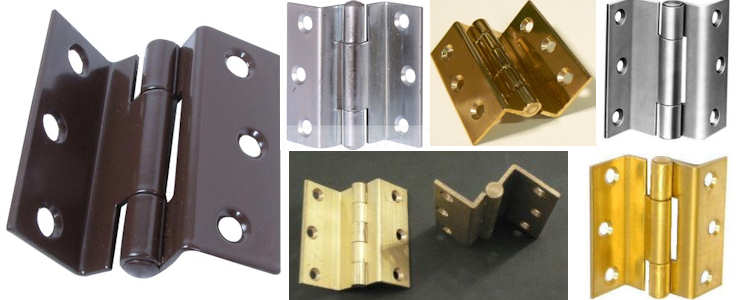

casement hinge --- A type of hinge specifically for use with a casement window. There are several styles ranging from fairly simple to moderately complex. Examples:

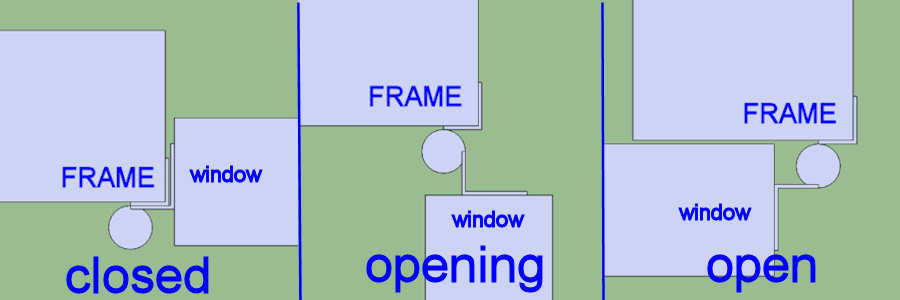

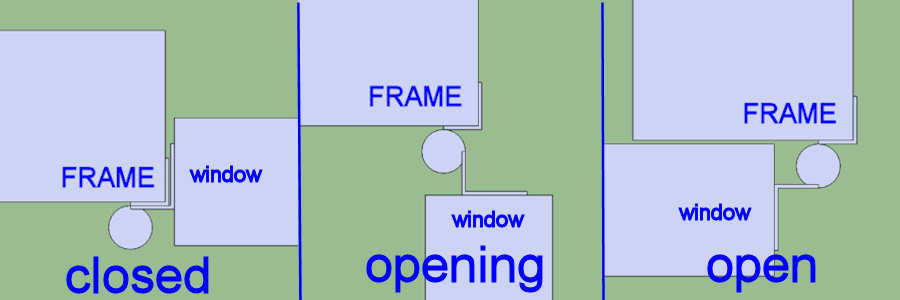

casement window --- A window that has hinged opening sashes, as opposed to ones that slide up and down in a track

casing --- Although the word means the housing or outer shell or covering of something, in woodworking it is generally used to refer specifically to either (1) the exposed molding or framing around the inside or outside of a window or door or (2) the shell of a power tools such as a hand held power drill.

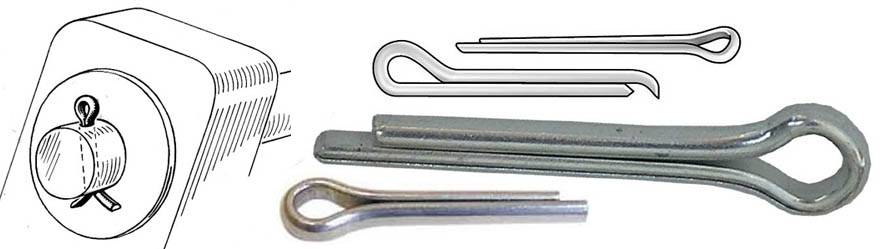

castle nut --- A nut that has a slotted ridge around the top, making it look very much like a castle guard tower. It is used with a bolt that has a hole through the end through which a cotter pin is inserted and then bent around the castle nut so that the nut becomes captive and cannot vibrate off. Also called "slotted hex nut". Examples:

catalyst --- A chemical compound or element that acts in a chemical process to cause, or speed up, the process but which itself is not actively involved in, or consumed by, the process. Weird as it seems (to me anyway) there are chemical processes that only take place when a catalyst is introduced even though the chemicals in the reaction are exactly the same as without the catalyst it's just that they don't react with each other without the presence of the catalyst and yet the catalyst itself is not affected. In woodworking, you will see this term in discussion of adhesives and finishing agents, but it is used rather loosely and in a somewhat colloquial sense to mean any agent that meets only half of the definition of a catalyst, that half being the part about it speeding up a process, but ignoring the other half which is that a catalyst is not itself actively involved or consumed. So an accelerator, for example, that is itself very actively involved in causing a finishing agent to dry more quickly might be called a catalyst even though technically it is not.

catalytic --- involving a catalyst

catch --- In lathe turning, when the lathe tool digs into the wood and holds it instead of scraping or slicing it, and the lathe consequently hesitates or stops turning completely. Catches are the bane of novice turners and overly aggressive pros. Catches can cause nasty gouges in the workpiece and if the lathe tool is positioned with too much of it hanging out over the tool rest, a strong catch can break or bend the tool or grab it out of the operator's hand, any of which events would be considered a Bad Thing and likely to cause loud exclamations of words that we do not encourage our children to use.

catenary --- The curve formed by a loose hanging chain or rope. Contrary common belief, this curve is NOT a parabola, although it looks a lot like one. Technically, it is a hyperbolic cosine. I have created a catenary and a parabola with similar parameters and show them overlaid on each other below. The parabola is the higher of the two. Because I only created half of each curve and then mirrored them, the joint at the bottom is not quite precise and the point here is not to be all that accurate in the demonstration of the two curves but simply to emphasize that they are not the same.

cathedral door --- Door style with a curved top. Used in cathedrals (thus the name) but also in furniture such as cabinets and break-fronts. Here are a few examples of the style used in cabinet doors and decorative panels:

cathedral grain --- The effect in some flat cut planks where the grain lines form a U- or V-shape. In veneer this is called crown cut. Examples:

cat's paw --- A type of cluster burl where there is an isolated group of small eyes that fall more or less in the shape of a cat's paw. Below is one example and to see more, click here: cat's paw pics.

caul --- A Sheet of wood or metal used distribute pressure when pressing veneer onto a substrate. Direct clamping of veneer is a really bad idea because localized pressure (from a clamp) will stay localized without a caul.

caulk --- [noun] A waterproof compound used to fill and seal joints or seams. Caulks are available as putties, ropes, and compounds extruded from cartridges called caulking guns and are formulated from a wide variety of materials. The earliest caulking material was mud. Some modern caulking materials have some adhesive strength as well as being sealants.

caulk --- [verb] To use caulk (see noun definition directly above)

caulking --- [verb] Using caulk

caulking --- [noun] synonymous with caulk

caulking compound --- synonymous with caulk

caulking gun --- A cylindrical metal frame with a handle that shoves a pushrod that goes into the back of a plastic or cardboard tube of liquid, usually a highly viscous liquid, that is a caulk or an adhesive. The liquid comes out the other end of the tube in a stream, the size of which is controlled by a nozzle on the tube that can be cut to a range of opening sizes. The construction is such that inserting and removing tubes is very easy. Most models have a thick metal wire that swivels away from the side or the end and that is used to puncture the gummed-up end of a tube that has been previously used and in which the caulk has cured at the very end and needs to be cleaned out so that fresh caulk can come through. Examples:

CC --- Cement Coated (a nail type)

C clamp --- A loose (as opposed to bench-mounted) clamp more or less in the shape of the letter "C". Sometimes called a "G" clamp. C clamps come in sizes from very small (a couple of inches) to quite large (a couple of feet), and have an advantage over bar clamps of a deeper throat. Examples:

Celcius --- A temperature measurement system based on water freezing at 0 degrees and boiling at 100 degrees. Compare/contrast to Fahrenheit.

cell --- A general term for the atomic units (The smallest, microscopic, structure) of plant tissue, including wood fibers, vessel elements, and other elements of diverse structure and function.

cellular wood panel --- Similar to lumber core plywood panels but the battens and laths that form the core can be spaced either parallel or in lattice form so the panels are relatively light but have some strength.

cellulose --- The structural component of the primary cell wall of all green plants including trees. It's what gives trees tensile strength. Cellulose derived from wood pulp is the major constituent of paper and cardboard. Although cellulose is 100% sugar molecules, due to the angle of bonding, cellulose is not digestible by humans and is often referred to as "dietary fiber" or "roughage". That's why eating trees never really caught on with humans. Wood is nominally about 50% cellulose, 20% hemi-cellulose (cross-linked cellulose), 25% lignin, and 5% "other stuff" such as gum, resin, sand-like crystals, and extractives. There are two types of paper production from trees, one in which the lignin is removed (delignification) and the process produces white paper for stationary and the like, and the other in which the lignin is retained and the process produces brown paper for paper bags and cardboard.

cell wall --- The enclosing membrane of a cell.

Celtic grind --- synonymous with fingernail grind

cement --- (1) In the general, Enlish-language sense of the word, cement means an adhesive, so you will see things like "cementing" meaning the same as "gluing", and contact cement which is not the same as the cement described below, and other general uses where the term does not refer to the specific substance described below.

cement --- (2) A building material that is a powder made of a mixture of calcinated limestone and clay and is used with water and sand or gravel to make concrete and mortar. The most commonly used cement is Portland cement, which is a particularly good variety, originally developed in England.

cement coated nail --- A nail coated with adhesive ("cement") to give it a very rough surface for greater holding power.

center gap --- see core gap

centered heart --- see boxed pith for a discussion

centerline --- (1) On any tool that has rotational action, the centerline is the axis of rotation.

centerline --- (1) On a lathe, "centerline" also (in addition to the rotational axis) refers any point on the edge of the workpiece that is the same height off the floor as the rotational axis and on the turner's side of the piece. In other words, a point that is a 9 O'clock when the piece is viewed looking into the headstock. This centerline is a reference point for the correct placement of the tool rest and lathe tools.

centerline --- (2) Either the position itself, or a physical drawn line demarking the position, along the center of the thickness, width, length, or axis of a workpiece.

center matching --- A form of veneer matching where an even number of veneer components or leaves, not necessarily of equal width, are matched outwards from the center of a panel to achieve horizontal symmetry. This is an extended form of book matching.

center punch --- A simple device to mark a surface at a point where a hole is to be drilled. There are two form of this device. The first, for wood, is a simple steel rod with a point on the end and can be home-made by just grinding down a screwdrive tip or even just a piece of bar stock. The second, for metal, is formally called a machinist center punch and I describe it with that term. Examples:

centers --- (1) On a lathe, the parts at each end of a spindle and that are pressed against it to hold it in place, thus the expression "turning between centers". See also cone center, dead center, drive center, live center and ring center. Centers, especially those that mount in a tailstock will usually be part of a Morse taper or other machine taper.

centers --- (2) The inner plies of a plywood panel. Some definitions specifically state that such use of the term implies that the grain of the centers runs parallel to the grain of the front and back plies but that definition restricts the term to only the one innermost ply and I have seen it used to mean all but the outer plies (that is, synonymous with core).

centrifugal force --- The force acting on a body revolving around a center and which causes the object to fly away from that center if it is released. This is the force that causes pieces to fly off when work is revolving on a lathe. The opposite force is the centripetal force. So if you swing a rock tied to a piece of string around over your head the rock is acting on the string with a centrifugal force and the string is acting on the rock with a centripetal force and if the two stop balancing each other, your neighbor's window may have a problem.

chain saw --- A specialized portable power saw with heavy teeth mounted on a continuous loop around a long slightly oval shaped plate called the bar. The end of the bar is called the nose and starting a cut at the nose can cause dangerous kickback. Large versions are used for logging operations and are gasoline-motor powered, as are many smaller versions but some small versions are available for back-yard use that have electrical motors. The teeth are specially designed to cut and chip out a path in full sized trees and large tree limbs. Tree surgeons and back-yard casual users may use them for pruning smaller branches as well. The electric versions are lighter, quieter, and slightly safer but if you're going out in the woods with one the extension cord would be a bit of a problem. Here is an example of an electric motor chainsaw and also a gasoline powered one:

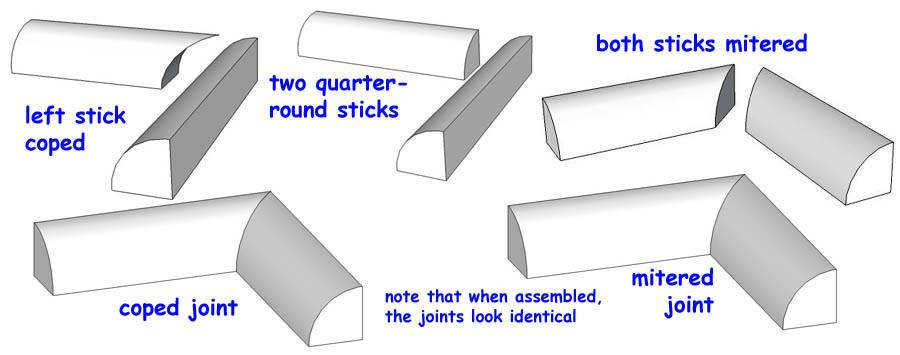

chair rail --- A strip of molding that is placed horizontally along a wall at about waist height. As the name suggests, the original purpose of such molding was to protect walls from chair-backs, but it is now often used simply as a decorative touch. The part of a wall below the chair rail and down to the baseboard is called the dado and chair rails are also known as "dado rails". Examples:

chalking --- Formation of a powdery surface condition, and the associated loss of gloss, on a finishing agent. Chalking occurs because of weathering, heat, exposure to uv, or other destructive environmental factors.

chambered pith --- A form of pith in which the pith is divided up by cell walls into little stacked cylinders along the length of the pith. Examples of chambered pith in small branches of (1) and (4) black walnut, (2) butternut, (3) hackberry, and (5) unknown wood:

chamfer --- [noun] The flat surface created by slicing off the edge or corner of a piece of wood or panel, usually at 45 degrees. See also bevel.

chamfer --- [verb] To cut edges or ends at an angle, but not a right angle. See also bevel

chamfered --- Having the edges where two surfaces meet removed lengthwise at an angle. See also beveled.

channel lock pliers --- Also called "tongue and groove" pliers, and less often "adjustable joint" pliers, these differ from the standard slip joint pliers in two ways, First, the gripping jaws are at an angle to the handles instead of a straight extension of them, and second, the opening/closing mechanism is based on a series of tongue and groove indentations that allow multiple settings for the size of the opening. Like slip joint pliers, they have serrated jaws and they may or may not have insulated handles. The exact curvature and shape of the jaws varies somewhat among brands. Examples:

character --- In wood, as with people, this is a loosely defined term. What exactly does it mean, with people, to say "he's quite a character"? In wood, it means something like "having interesting figure".

chatoyance --- an alternate spelling of chatoyancy

chatoyancy --- [also chatoyance; both are nouns and the adjectival form is "chatoyant"] The property whereby something reflects light quite differently depending on the viewing angle. With wood, this can be really striking, especially in pieces with ray flakes, which can go from dark to light as you move the wood's angle in the light. On wood with large ray flakes, the flakes themselves can change color in an obvious and attractive fashion, but where chatoyancy really applies is in woods with multitudinous small ray flakes that cause the entire surface of the wood to change as you move it in the light. It gives the wood a "shimmer" that just can't be captured by still photographs. There are other wood grain characteristics that can create chatoyancy besides ray flakes. It can be particularly striking in woods that have interlocked grain that creates a mottle or ribbon stripe figure and it can also show up in woods with a curly figure. Having said that it can't be captured by a still photograph, I will now produce a still photography which does not quite demonstrate chatoyancy but which is of a piece of wood that DOES show beautiful chatoyancy. This is sipo with a polyurethane finish and the chatoyancy in this case is due to multitudinous small ray flakes.

chatoyant --- having the property of chatoyancy

chatter --- (1)[noun] A rapid, and usually noisy, vibration of a workpiece due to interaction with a moving tool edge, or of the tool edge itself due to interaction with a workpiece. Chatter tends to be bad because it represents an uneven operation of a cutting tool, and it is not a happy sound for a woodworker since it means things are not going smoothly.

chatter --- (2)[noun] Speech emanating from one's spouse when one is trying to concentrate on a woodworking project. This is not a happy sound for a woodworker, because unless one changes concentration from the woodworking project to the chattering, things will not go smoothly later.

chatter tool --- A tool used on wood on a lathe to create a series of light gouges or dents around circular path. The tool may have various kinds of handles but the working part is a thin, fairly narrow, metal blade that is touched lightly to the wood and which develops harmonic vibration (called chatter thus creating a regular series of gouges/dents. The pattern thus obtained is called chatter work.

chatter work --- On a wood lathe, there is a technique for producing a decorative pattern by having a thin lathe tool called a chatter tool that is presented to the workpiece surface in such a way as to deliberately cause the tool to chatter harmonically to produce a wave-like pattern on the work surface. This effect is sometimes produced UNintentionally and has to be smoothed over. When this harmonic chatter is done deliberately, it is called chatter work or "harmonic chatter"; when done UNintentionally, it is generally just called "harmonic chatter" (and sometimes other names that should not be printed in a family magazine).

check --- (1) A lengthwise separation of wood that extends along (that is, parallel) to the wood grain but generally running radially across the annual growth rings. This is a drying defect and is commonly caused by differences in radial and tangential shrinkage or because of uneven shrinkage of the tissues in adjacent portions of the wood. Checks that run all the way through a board are called through checks and checks that don't go all the way through are called surface checks. A check can be internal to the piece and not become visible, particularly on a thick board or slab, until it is worked.

check --- (2) As regards paint or other finish, see alligatoring

checkered work --- Any wooden object that is made by gluing strips of wood together and then cutting them across the laminations, shifting them one block off, and then regluing them to make a checkerboard patter. This can be done for a chopping block, and actual checkerboard (the game), or used in a segmented turning, etc.

cheek --- The vertical side of a tenon. (see also vise cheeks) Example:

chemical brown stain --- synonymous with brown stain

chemical resistance --- The ability of a finishing agent to resist damage from chemicals such as solvents, adhesives, and everyday spills such as coffee, softdrinks, and so forth.

chemical stain --- A chemical discoloration of wood that is believed to be caused by the concentration and modification of extractives. This may occur as part of the tree growth or it may occur as a drying defect in kiln drying, due to the heat of the drying process.

Chinese joinery --- Solid wood furniture construction methods that do not involve the use of nails or screws but rather elaborate joinery. These centuries old techniques include tongue and groove joints, mortise and tenons, and various types of dovetail joints.

chip --- (1)[noun] A small, generally irregular, portion of a solid material that has been removed by accident or due to involuntary mechanical action (such as ice causing chips to come off of a stone or brick), or on purpose as in chip carving. This could be a small chunk of wood that broke off when a cutting edge exited the side or end of a plank. It could also be a small section of a hardened finishing agent that came off due to the finish being struck by a hard object.

chip --- (2)[verb] To cause the creation of the small items described in the noun definition above.

chipboard --- [this is the USA definition, not the UK definition] A paperboard, thicker than cardboard, used for backing sheets on padded writing paper, partitions within boxes, shoeboxes, etc. In the UK, chipboard is a term used for what in the USA is called particleboard.

chip carving --- A wood carving technique done on a flat surface using notching tools such as a short-bladed knife (see chip carving knife) to remove chips of wood. Chip carving is usually used to create geometric designs rather than the more flowing designs done in relief carving, where cuts are often much longer than the short cuts of chip carving. Also, chip carving does not have any undercut areas like what you see in relief carving. Examples:

chip carving knife --- A very short-bladed knife, with a sturdy wooden handle, used to do chip carving. Examples:

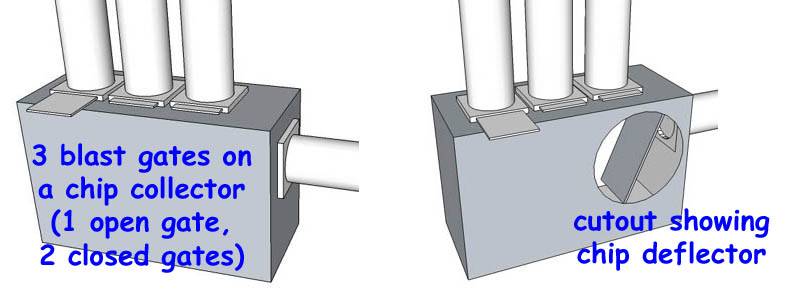

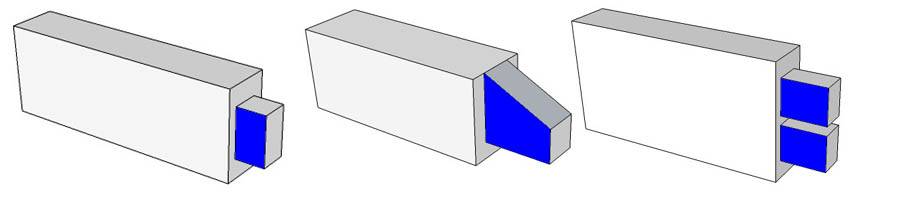

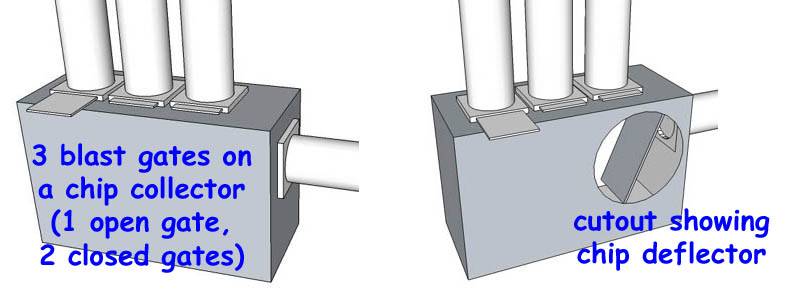

chip collector --- A (usually homemade) bypass tub or box that is put in-line in a dust collection system in a way that traps wood chips and takes them out of the main flow of the system. Most often the system blast gates are put directly above the chip collector, as this conveniently puts everything all in one place. Here's an example of a simple design (this has the outflow to the dust collection bag going off to the side but it would be common to have it coming out of the top along with the blast gates):

chip marks --- Tiny indentations in the surface of a plank caused by small chips of wood being forced into the surface during the process of dressing the wood.

chip-out --- [also chipout] Wood that is chipped off of the edge of a piece as a cutting edge exits from the wood surface. Some woods are more brittle and thus more subject to chip-out than others, and it's a good idea to get to know such wood characteristics before you begin working with a wood that is new to you. Also, it's a good idea to think about your cut in relation to the wood grain. Sometimes chip-out can be made less likely simply by cutting from one side of a board instead of the other. Chip-out can be reduced by proper use of backing boards and by keeping cutting edges sharp. Chip-out is particularly prevalent in drilling if no backing board is used along with twistdrillbit drill bits. When using a router across the end grain of a plank, there is a strong tendency for chip-out to occur as the blade exits the edge, and sometimes a backing board won't help because the edge has already been routed. In that case, several shallow passes of climb cut can be used to avoid chip-out. Also see tear out. Here's a piece of osage orange and canary wood (on top of mahogany) both of which have chip-out from a saw blade. The osage orange chip-out is likely due to a brittle section of wood and no backing board and not even necessarily a dull blade, whereas the canary is a long running edge full of chip-out, due to both a dull blade AND the lack of a backing board.

chipped --- Has had one or more chips removed.

chipper --- The inner blades in a stacked-head dado cutter. These blades do most of the work in removing the bulk of the wood from the dado, while the outer blades cut clean edges along the sides. Usually the chippers have a slightly smaller diameter than the outer blades, thus resulting in a horned dado cut. See stacked head dado cutter for illustrations of chippers.

chipping --- see chip

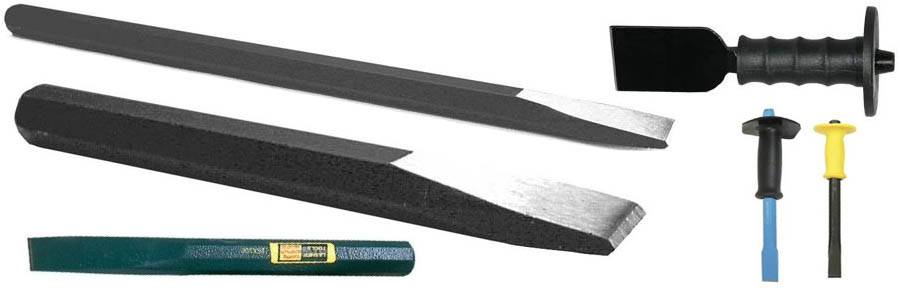

chisel --- A metal tool, usually steel, with a straight sharpened edge at one end and a handle on the other. It is used to chip, carve, engrave, turn, or otherwise cut into a solid material such as wood, stone, or metal. A chisel may be forced into the workpiece by hand or by blows of a carving mallet on the top of its handle or in the case of a lathe chisel, pushed into turning wood while being supported by a tool rest. Chisels come in an almost unlimited variety of sizes and shapes, depending on intended use. Although there are three fundamental types of chisels, there are numerous terms describing chisels and their attributes, so I have listed below a large number of such terms with links to their definitions. The three fundamental types of chisels, based on general use (not size or shape) are carving chisels, joinery chisels, and lathe chisels. The sister tool, gouges also come in carving and turning types but there are no joinery gouges. See also chisels vs gouges.

Fundamental chisel types:

carving chisel --- used for wood carving)

joinery chisel --- used for making/cleaning wood joints

turning chisel --- used in wood lathe turning

Other types of chisels and chisel-related terms (see terms for illustrations): NOTE: INCOMPLETE SECTION --- many of the terms below are not yet defined

- bedan --- thick, slightly beveled cross section turning chisel

- bench chisel --- same as bevel edge

- bevel edge chisel --- like firmer chisel but with beveled edges

- cannel --- a hollowed out groove along the length of a chisel or gouge

- butt chisel --- short length bevel edge chisel

- cold chisel --- hefty, for stone / brick / concrete

- corner chisel --- 90-degree-edge joinery chisel for cleaning square-edged holes

- cranked chisel --- any chisel with a dog leg bend between the tip and the handle

- dogleg chisel --- same as cranked chisel

- dovetal chisel --- joinery chisel for cleaning out dovetails

- firmer chisel --- rectangular cross section, thicker than paring chisel

- flooring chisel --- like a cold chisel but for wood

- forming chisel --- same as firmer chisel

- framing slick --- large blade, pushed manually, never struck with a mallet

- in-cannel end bevel is inside the cannel

- lathe chisel --- same as turning chisel

- mortise chisel --- square cross section, thick-bodied joinery chisel, for cleaning out mortises

- out-cannel --- end bevel is outside the cannel

- oval skew --- skew chisel with oval cross section

- paring chisel --- trapazoidal cross section and thinner than a firmer chisel

- parting tool --- a type of lathe chisel

- scraping chisel --- various types, for scraping operations

- skew chisel --- the end is straight but angled relative to the body (usually 60 degrees)

- slick --- same as framing slick

- spoon chisel --- carving chisel with spoon-like cross section

- see also: gouges

chisels vs gouges --- Although there is total sloppiness in the common usage of these terms, there IS a clear and cleanly defined technical distinction between chisels and gouges and it is simply that chisels always have cutting edges that are flat and gouges always have curved cutting edges. Both carving gouges and lathe gouges tend to be called chisels in common usage and it is absolutely normal to see a "chisel set" which contains gouges.

A chisel may have a "V" shaped pair of straight edges (typically at either 60 degrees or 90 degrees to each other), but if something has a "U" shaped cross section , no matter how deep or shallow, it should not (technically) be called a chisel, but is a gouge. Also, a chisel can have a curved cutting edge that is all in the same plane as the body of the tool. The amount of curve on a gouge's cutting edge is known as the sweep but there are no standards for measurements, so different manufacturers describe sweep differently and some care is needed when comparing tools from different manufacturers. Sweep is also known as "smile", although I have not often seen that terms used. When a gouge has a cylindrical barrel with a "U" shaped channel cut out of it, that channel is called the cannel. Both chisels and gouges are normally mounted on a wooden handle by way of a tang or a socket although in recent years, lathe gouges with metal handles have become popular. Despite the relatively high expense of these metal handles, they can be cost effective because they have set screws to allow them to be used with multiple blades (although only one at a time, of course).

chlorophyll --- A green pigment found in most plants and algae; it is responsible for absorption of light, allowing photosynthesis to occur.

chop saw --- synonymous with cut-off saw

chord --- (1) A straight line joining two points on a curve

chord --- (2)The upper and lower members of a truss. The members joining the chords are called webs. The term chord is also sometimes used to refer to beam flanges. See also parallel chord truss.

chroma --- see color terms

chuck --- A clamping device that holds a tool or the material being worked on in a machine with a rotating action such as a lathe or drill press. Chucks for lathes may be designed to hold a workpiece by either compressing around its base or expanding into an existing cavity and they may consist of a set of jaws or a set of arcs or even a single screw. Also, some lathe chucks do not hold the workpiece directly but rather hold a face plate to which the workpiece is attached. Drill press chucks always press in on whatever is being held, usually a cutting bit, not a workpiece, but sometimes workpieces are rotated in a drill press for various operations. Chucks are normally tightened with a chuck key but some chuck are "keyless" and work with by the user twisting the end of the chuck. Battery operated hand drills often have keyless chucks. Here are some examples of both drill chucks and lathe chucks:

DRILL CHUCKS:

LATHE CHUCKS:

chucking --- The process of mounting a workpiece in a chuck. The opposite is unchucking.

chuck key --- A metal rod, often bent in a "L" shape or with a cross-bar on one end, with grooves that mate into an area in a chuck and when turned cause the chuck to open and close. Examples:

circular --- (1) Refers to motion that goes around in a circle as opposed to in a straight line. Compare/contrast to reciprocating.

circular --- (2) Round; having an edge that has all points equidistant from a center. There are several types of power saw (e.g. table saw, radial arm saw, etc.) that use circular blades, as opposed to the straight-line blades of handsaws and bandsaws.

related terms:

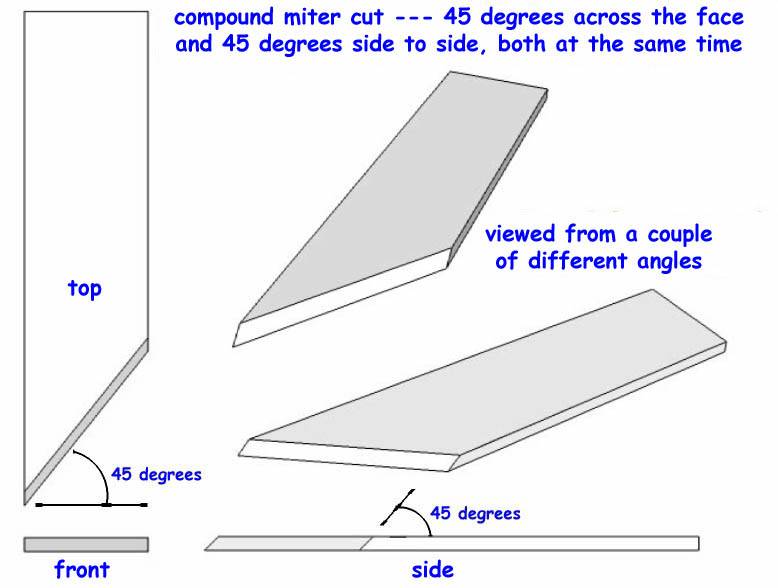

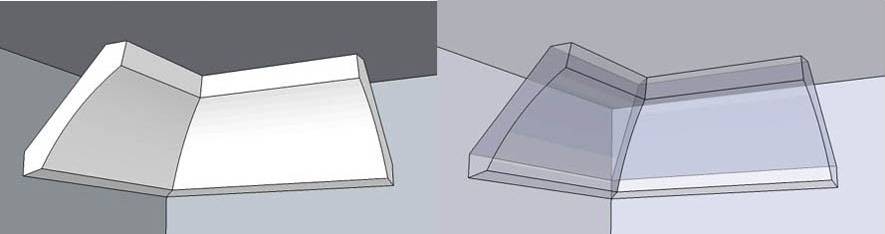

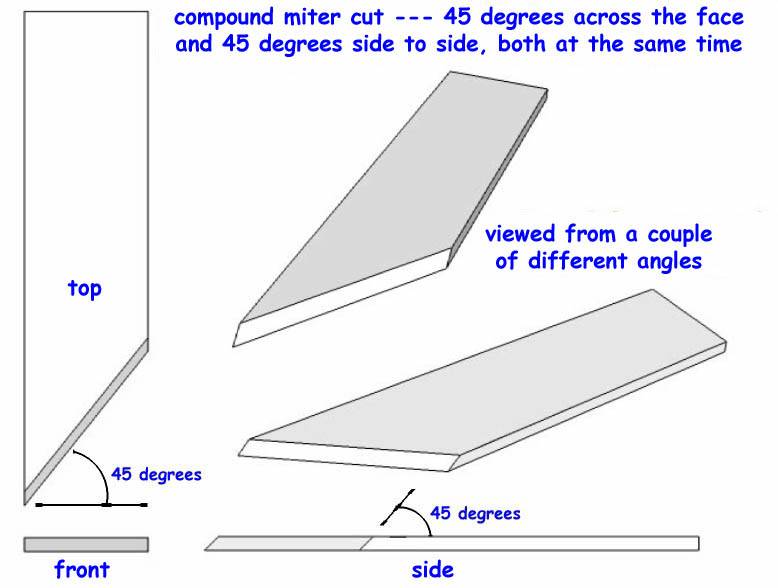

circular saw --- Any power saw with a circular blade. There are two types, portable and stationary. Within stationary, there are four basic types: circularsaw mill, the table saw (which has several subtypes), the compound miter saw, and the radial arm saw. The circularsaw mill is typically much bigger and more powerful but less flexible than other types since the mill version is purely there to slice logs but the others have a far greater range of use. The compound miter saw is a less flexible version of the radial arm saw (with the most outstanding difference being that the radial arm saw can rip cut and the compound miter saw cannot). The compound miter saw has a variant, the sliding compound miter saw that makes it more like a radial arm saw, but it still can't rip. "Buzz saw" is another name for circular saw, although I believe that is now an obsolete term, mostly applied to large sawmill saws, and I've never seen it applied to a radial arm saw or compound miter saw both of which are relatively modern inventions.

circular saw blade --- A flat, round saw blade having teeth on its perimeter. Used in the various types of circular saws. In the examples below, I have put in proportionally sized versions of 5", 7", 10", and 12" diameters blades, which is about the full range of hobby and small-business sized blades. The smaller two would be used almost exclusively in portable circular saws and the larger two mostly in radial arm saws or table saws. The number of teeth in the circumference of a blade will vary greatly depending on the diameter of the blade and the intended use. Rip blades will have fewer teeth, perhaps 24 to 36 in a 10" blade whereas cross cut blades will have perhaps 36 to 80 in a 10" blade depending on how fine a cut you want and how much you want to pay. My own preference for a rip blade is 18 teeth on a 10" blade, but I can't seem to find them anywhere these days so I settle for 24. Some blades are high speed steel (if you ever see one made of carbon steel, leave it there in the discount bin for the next sucker that comes along) but the better blades will have carbide tips which last much longer. The economics of it is something like this: they cost twice as much but last 5 times as long. It's a no-brainer. In the examples below, the 5" blade is a rip blade (and it has my desired 18 teeth, BUT it's a 5" blade --- I want 18 teeth on a 10" blade and that's what I can't find) and the others are cross cut blades. The examples below are all wood blades, but there are specialty blades for cutting everything from metal to concrete. In use, these blades (particularly in stationary saws) are usually supported on the arbor by a stiffening collar that dampens wobble and reduces blade whine.

circularsaw mill --- The traditional sawmill, using a circular saw (a large version of a table saw). Compare/contrast to bandsaw mill. Circular saws are thicker (larger kerf) than band saws and so produce more sawdust and less lumber. Also, in a circularsaw mill, logs can only be cut moving on the carriage in only one direction, then the carriage returns for the next cut whereas in a bandsaw mill, the blade can have teeth on both edges and cut the cant in both directions.

circular sawn --- Refers to a piece of lumber that was cut by a circular saw and which therefore has curved saw blade tooth marking on the face. Compare/contrast to band sawn.

clamp --- [verb] to apply pressure to hold parts together, either while an adhesive sets or in order to keep a workpiece in place while operating on it with portable tools such as a chisel or a hand-held powered sander.

clamp --- [noun] A device that applies pressure, usually by some application of a wedge either directly or indirectly (via a threaded device). Some types of clamps used in woodworking are: NOTE: INCOMPLETE SECTION --- some terms below are not yet defined:

- bar clamp --- uses a long metal bar between the jaws

- cam clamp --- uses a cam to exert pressure

- C clamp --- shaped like the letter C

- corner clamp --- two-way clamp for corners

- F clamp --- same as bar clamp

- finger clamp --- in woodworking, this is a small strap clamp

- G clamp --- same as C clamp

- holddown clamp --- goes in a hole in a bench, uses bench as one jaw; tightened/loosened by tapping with hammer

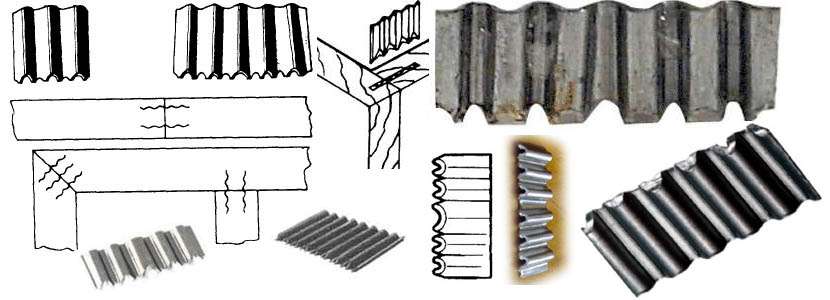

- pinch dog --- "U" shaped staple-like metal that is driven into the end of planks being glued up

- pipe clamp --- like a bar clamp but with a metal pipe instead of a bar

- pushdown clamp --- used in electrical connections

- screw clamp ---

- shaving horse --- a sitting bench plus a device for clamping large tubular items

- spring clamp --- uses a spring, not a threaded rod, to provide clamping force

- strap clamp --- uses a strap, encircling the object being clamped

- swing clamp ---

- toe clamp ---

- toggle clamp --- a bench mounted clamp with a pivot and lever "on/off" action and limited range; uses bench as one jaw.

- wedge clamp --- (1) direct use of a wedge for a clamping action

- wedge clamp --- (2) a specific type of clamp that is not a woodworking tool

clamping block --- A small block of scrap wood that is put between a workpiece and either end of a clamp in order to protect the workpiece from being scraped or dented by the clamp. Some clamps come with plastic covers over the ends so that clamping blocks are (supposedly) not necessary but for clamping soft wood in particular, many of us prefer to use clamping blocks anyway.

class --- see taxonomy for a discussion

claw --- The type of hammer peen that is split in the middle so it can be wedged under nailheads so that the hammer can be used to pull the nail out.

claw and ball --- an elaborately carved type of furniture leg bottom, often used with cabriole legs. Examples:

claw hammer --- The most common type of hammer, this version has a head that is a striking surface on one end that is used for (among other things) driving nails and a split chisel-like thingy on the other end (the "claw") that is used for pulling nails. This is what most people think of when they say "hammer". The head of a claw hammer is very hard steel but somewhat brittle, so it should not be used to pound on other large steel objects. For that, a ball peen hammer is more appropriate. The claw portion is curved to provide leverage in extracting nails. If you see what looks like a claw hammer but it has a straight claw, that's a framming hammer. Claw hammers are typically made in one of two ways. The first version is a wood handle (usually hickory) set into a steel head and then wedged in place with a metal wedge (see hammer wedge). The second version is made of one piece of metal from the head down through the handle, which is often just a tang that is covered with leather or rubber to help absorb shock. Examples:

claw nail puller --- This tool comes in several sizes and slightly varying shapes, but it is basically just a small specialty crowbar designed for pulling nails. It is often no more effective than just the claws on a claw hammer. For a more effective tool, compare this to the nail puller. Examples:

clean and bright --- The freshly manufactured appearance of lumber as it comes from the planer.

clean and dry --- A phrase used in woodworking with exactly the same meaning it has in any normal English language context and used to describe the desired condition of a surface prior to finishing; free of oil, grease, wax, moisture, and any other contaminant that may affect the adhesion of a finishing agent or adhesive.

clear --- A wood product (e.g. flooring or lumber) grade that allows only a minimum occurrence of knots, mineral streaks, and other flaws. Some small exceptions might be made for certain species and/or depending on the application. Most often this grade is to distinguish "clear pine" from "knotty pine". Clear is an even higher standard than FAS. Note that clear is about appearance and says nothing about structural characteristics. Example:

clearance angle --- The angle between the bevel at the end of a tool (generally a chisel) and the surface of the workpiece to which the tool is being applied.

clear cutting --- The harvest of all the trees in an area in a single logging operation. Clear cutting sometimes is taken to have a negative connotation because it denudes an area of trees, but actually it is used to aid species whose seedlings require full sunlight to grow well and thus can be more ecologically friendly than partial cutting.

clear face --- A board side that has no defects.

clear span --- The horizontal distance between the inside edges of the supports of a load bearing member. The number of internal members in a truss, for example, will depend on the length of the clear span that it has to bridge. Compare/contrast to total span.

clear vertical grain --- A lumber grading term that means no knots ("clear") and with the annual growth rings perpendicular to the face of the plank ("vertical grain"), which of course means quartersawn. As with the term quartersawn, You can get into religious arguments about whether it means "true" quartersawn, that is, growth rings at or VERY near to, 90 degrees to the face, or whether instead it is meant to include any angle up to [add your own choice of definition here]. Personally, I'm an engineer and to me something that leans over, say 30 degrees, is absolutely NOT vertical, but in woodworking 30 degrees would be well within many definitions of quartersawn.

cleat --- A term with several meanings, but as regards woodworking, this generally means a piece of wood that is specifically placed so as to support another, usually larger, piece. An example would be a block of wood nailed to an upright support directly underneath a horizontal beam so as to provide extra support for the horizontal beam.

cleave --- To separate or cut with a sharp instrument; to separate along a natural line of separation. As regards wood, it usually means to split along the grain, as is done with a froe.

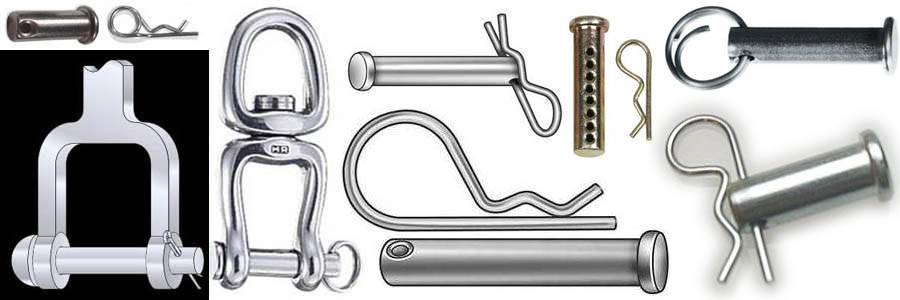

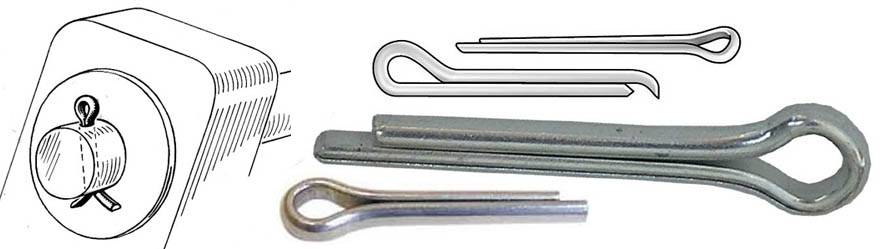

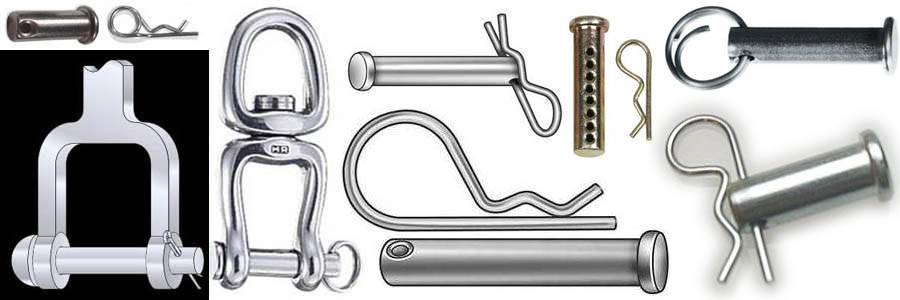

clevis pin --- A short metal rod with a head on one end and a hole drilled in the other end, so that the pin can be put through a hole and then be fastened in place by a cotter pin through the hole in the pin. There is a special type of "cotter pin" used with clevis pins, as shown in the composite pic below. This form of cotter pin has one leg ridged to hold it on the clevis pin and the legs are not bent after insertion into the pin. This form of cotter pin is more readily removed than a standard cotter pin. Clevis pins are also attached with wire rings much like a key-chain ring. Clevis pins are used to attach small rotating parts to each other, to attach turnbuckles to a chain loop, etc. Examples:

climb cut --- A router cut made in opposite direction from normal. That is, a cut made such that the cut is in the same direction as the pull from the rotating motion of the blade. This is NOT a good idea for full cuts, because control is poor, but it is invaluable as a way of avoiding edge chip-out by making a series of very short, shallow climb cuts (until you have made a short full cut) just long enough to assure that the bit won't cause chip-out as it exits from the edge when making the full cut in the normal direction (where the blade's rotating motion pushes against the wood as the cut is made). If the edge is still square, a backing board is preferable to a climb cut, especially if you are not accustomed to making climb cuts, but if the edge has already been routed, a backing board won't work. The process of performing a climb cut is also known as "backrouting".

clinching --- The technique of driving an over-long nail through two boards and then bending over the exposed end to provide a very tight, strong clamping action.

clinometer --- An instrument used to (among other things) determine the height of a tree by measuring the angle to the top of the tree. Along with the angle, you measure the distance from the device to the tree and then simple trigonometry gives you the tree height.

clip on hinge --- add definition

clockwise --- Having rotational movement in the same direction as the hand of a clock (the top of the rotating object is moving to the right). In face turning, this relates to inboard and outboard. Compare/contrast to counterclockwise.

closed coat --- see discussion with open coat

closed cut valley --- A method of putting shingles on a valley where one roof plane’s shingles completely cover the other’s. The top layer is cut to match the valley lines. Compare/contrast to woven valley and open valley.

closed face --- the tight side in veneer

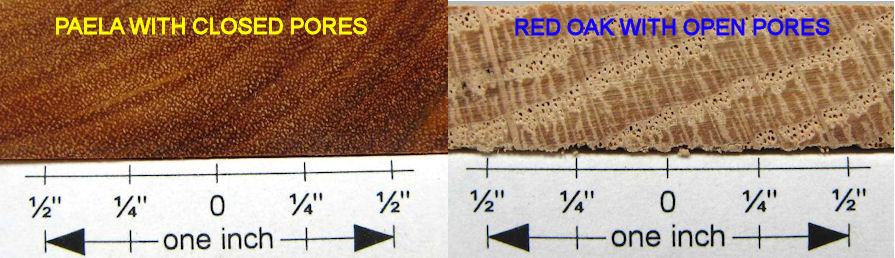

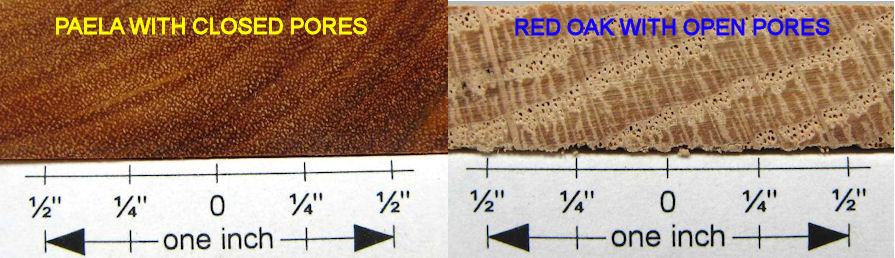

closed grain --- NOTE: the word here is "closed" as in "not open", not "close" as in "not far apart" --- this distinction is important because of the similar term "closegrained". It means that the pores in the wood are closed (and usually small as well, although there can be large closed pores such as those in white oak which are technically "open" in size/configuration but which are "closed" because they are blocked by tyloses) and is generally meant to be synonymous with fine textured, although when discussing the finishing characteristics of wood, fine textured [if applicable] is a more appropriate term than closed grained since a wood with closed pores is not automatically fine textured. NOT to be confused with close grained which has to do with growth ring spacing, not texture. Contrast to open grained (open pores). Example:

closed pore --- synonymous with closed grain

closed side --- the tight side in veneer

closed soffit --- A technically incorrect term that refers to what is more properly called a "closed soffit area", which just means an area that is enclosed by a soffit. see soffit for further discussion and related terms. Compare/contrast to open soffit

closed staircase --- A traditional staircase in which there are both treads and risers. Compare/contrast to open staircase.

close grained --- NOTE: the word here is "close" as in "not far apart", not "closed" as in "not open" --- this distinction is important because of the similar term "closed grain"

close grained --- (1) synonymous with tight grained and generally synonymous with fine grained. Compare/contrast to open grained and loose grained.

close grained --- (2) Sometimes used, incorrectly I believe, as a synonym for fine textured and the reason I believe it to be incorrect in that sense is that a wood that has close annual growth rings does not automatically have fine texture (although it usually will). I think this is a use where the user has gotten it confused with closed grain, which sometimes DOES go with fine texture.

cloth --- A type of backing on sandpaper

clothes press --- A freestanding, movable, upright closet for clothes or other storage. In earlier times, clothes presses were used in lieu of the kind of built-in closets now commonly found in houses.

cluster burl --- A localized section of burl that is isolated by normal wood from any other area of burl. There is one particular configuration of cluster burl that is known as cat's paw figure. Below is a pic of maple veneer with a cluster burl:

clutch head screw --- see security bolt

CMS --- Compound Miter Saw

coach bolt --- synonymous with carriage bolt

coach hinge --- I have found very few references to this term and most of those simply show a butt hinge

coach screw --- synonymous with lag screw

coarse grained --- (1) Refers to wood that has large, open (i.e. coarse) pores (see open pore. Compare/contrast to fine grained and medium grained.

coarsegrained --- (2) [less frequent use] Refers to wood that has widely spaced growth rings (see loosegrained.

coarse textured --- having a rough surface, often caused by, or at the very least accompanied by, large open pores. Compare/contrast to fine textured and medium textured.

coarse textured --- (2) having large cells in general and thus not amenable to a fine natural finish

coat --- [noun] A single layer of a finishing agent.

coat --- [verb] The act of applying a layer of a finishing agent to a surface.

coating --- Any material applied to a surface leaving a protective layer on that surface. For types of materials used in coating wood, see finishing agent. For a circular saw blade, this is a specially formulated chemical that adheres to the blade and that stays slick in order to reduce heat by both minimizing friction and binding and also by resisting pitch and gum buildup.

coating system --- A number of coats of finishing agents applied separately and in a predetermined order, at suitable intervals to allow for drying and curing, resulting in a completed job.

cobwebbing --- An effect where there is too-rapid drying of a coating, causing the surface to crack, sometimes in a pattern that looks much like a spider web.

code --- The rules set down by various governing agencies (generally local, thus the term "building code" generally means local building code) that specify minimally acceptable building practices. These include the size of framing members under various load conditions.

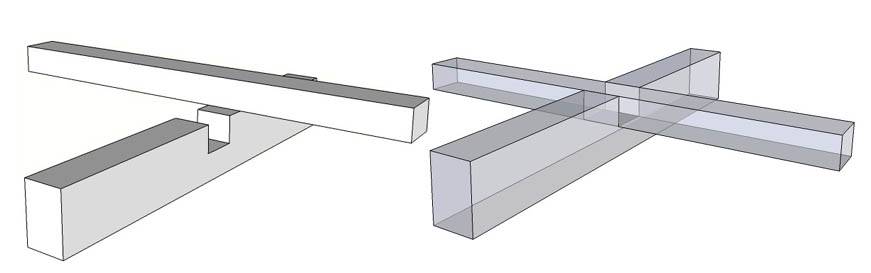

cogged --- There is a particular kind of scarf joint that is sometimes called a cogged scarf joint and I list it as such in this glossary, but I am not confident in the term. In researching "cogged", I found vague definitions, some of them contradictory, and no illustrations, and I am not confident that I know what it really means. Here are some of the entries I found, to at least give you a flavor of the term:

- cog --- the tongue in one timber, fitting into a corresponding slot in another.

- cogging --- A carpentry joint formed by two crossed structural timbers, each of which is notched at the place where they cross.

- joists and binders are connected by cogged joints

- mortise and tenon is a type of cogged joint

- The joint between rafter and chord is realized by a cogged joint

- " ... cogged joints, hereinafter generally referred to as notching ... "

- cog --- A tenon projecting from a wooden beam designed to fit into an opening in another beam to form a joint.

- cogging --- To join with tenons

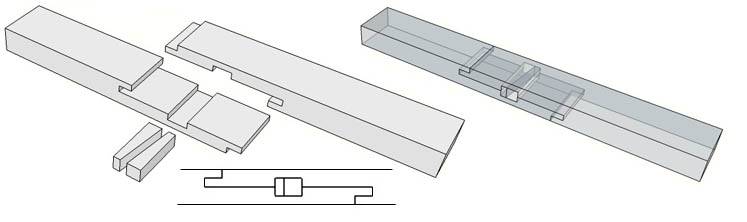

cogged scarf joint --- The term cogged is one that I have been unsuccessful in pinning down exactly, and the joint that I show here is one that I am not sure the term really applies to, but it's the term used with the joint where I found it, so I present it here. It is, at least in the example I found (and illustrated below) a double wedge (the term folding wedges is also used) put in the middle of a joint that is a slightly complex tabled scarf joint. For a knockdown joint the wedges can be left protruding slightly so that they can easily be tapped to remove them and disassemble the joint (which of course would not be glued). For a permanent joint, glue the wedges before tapping them into place, along with gluing the rest of the joint. This looks to me to be a very strong joint, but overly complex for most uses. Example:

cogging --- see cogged

cohesion --- The state in which the constituents of a mass of material are held together by chemical and/or other physical forces. When the components of a finishing agent for example, are not cohesive (that is, when they do not exhibit cohesion), that is a bad thing.

cohesive --- sticky; tending to adhere; tending to remain together; exhibiting cohesion.

cold checking --- The cracking of a finishing agent due to exposure to cold temperatures. Some finishing agents are particularly subject to cold checking if they are subjected to low temperatures prior to complete curing

cold chisel --- A hefty steel chisel made for cutting and shaping hard materials such as brick, stone, masonry, and concrete. These are usually just raw steel, but sometimes they come with a plastic hand guard. They may be whacked with a hefty steel hammer or mallet for strong cuts but also may be tapped with a hammer for edging and face cleanup. The original use of cold chisels was to cut excess edges from metal that was literally cold, not hot from the forge. Examples:

cold roof --- An insulated roof with a ventilation space above the insulation so that snow on the roof does not melt.