The HobbitHouse Ilustrated Glossary of Woodworking terms

LATHE TERMS

This set of terms having to do with lathes is extracted from the general glossary shown here: GLOSSARY

and links that are not local to this subset will put you back in the main glossary

for images of wood itself, go here: wood id site

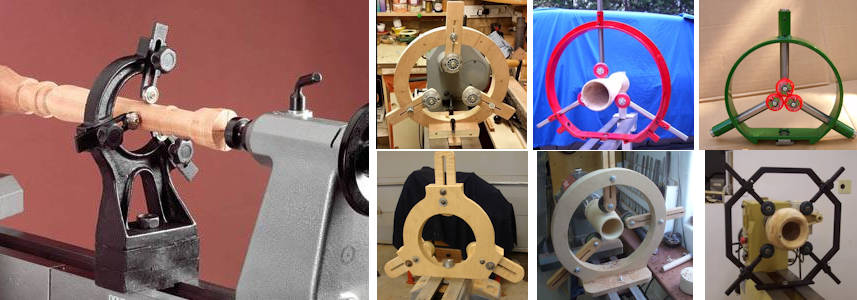

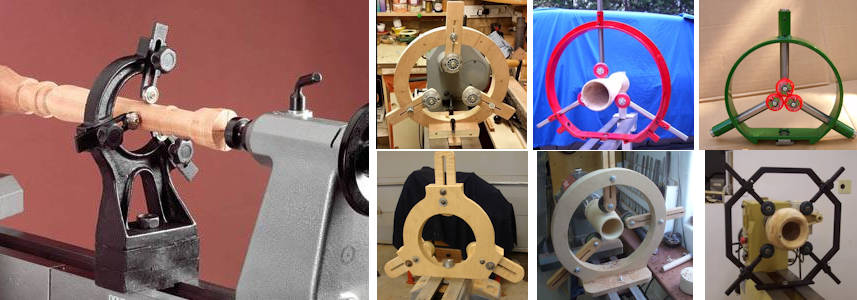

back steady --- A device to support a lathe turning object from the rear or the side so as to reduce chatter and allow the turner to apply more pressure to the lathe tool than would otherwise be safe. Also called a "bowl steady". See also spindle steady and tail steady. Examples:

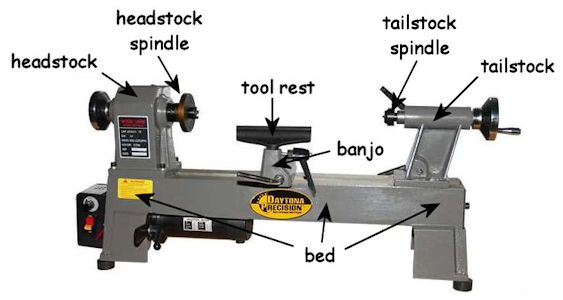

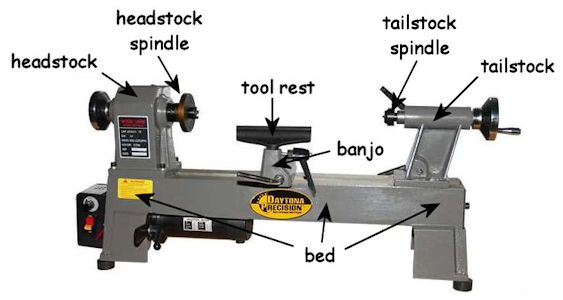

banjo --- The part on a lathe which slides along the bed and supports the tool rest. Illustrated with wood lathe.

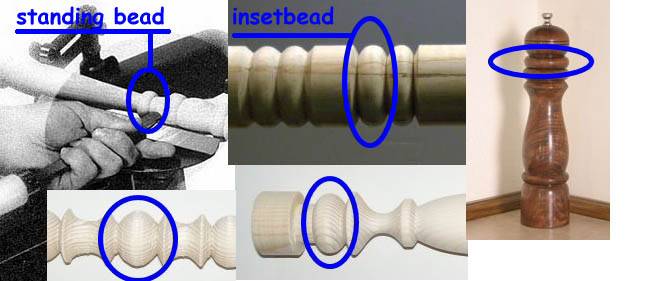

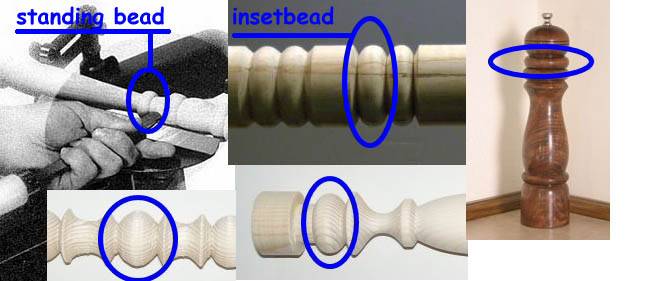

bead --- (1) In lathe turning, a bead is a rounded projection, usually turned on a spindle although they are sometimes done on face turnings. There are specialty tools used for making them; see, for example, beading tool, beading and parting tool, and bedan. If the bead stands fully exposed above the surrounding wood, it is called a "standing bead" but if the surrounding wood is more or less flush with the top of the bead, then the bead is called an "inset bead". Often, it's not particularly meaningful to try to categorize a bead as inset or standing, but some cases are clearcut.

bead --- (2) A semi-circular piece of molding.

bead --- (3) A small rounded, raised profile, routed along the edge of a board, particularly the edges of boards that are placed vertically to form a wall paneling.

Examples of type (1):

beading and parting tool --- A lathe tool that looks exactly like a squat parting tool and in fact is used as a wide parting tool in addition to being used to form beads. When the tool is used as a parting tool, the cutting edge is kept parallel to the axis of rotation of the spindle and the tool acts like a scraper just like a regular parting tool. When the tool is used as a beading tool, the cutting edge is rotated through a sweep and is not parallel to the axis of the spindle and the edge slices the wood rather than scraping it. Examples:

beading scraper --- synonymous with beading tool

beading tool --- A lathe tool; a small chisel used to form beads on a spindle. There really are two totally different types of beading tools. The first has a curved cutting edge and LOOKS like what one would use to form a bead, and the second has a square cross section and a flat cutting edge and looks like a squat parting tool. This second form comes in two flavors, depending on the way the end is shaped. When the end is cut as a wedge, so that the tool looks exactly like a squat parting tool, it is called a beading and parting tool. When the end is just sliced across, it is called a bedan. Both of those terms show their own illustrations, and what is shown below is the first form, the one with the curved cutting edge, which is used to scrape the spindle to create a bead. Examples:

bed --- As regards woodworking, this generally means some flat surface that is the base of an operation. For example, the flat part of a table saw or radial arm saw where the wood rides is called the bed. In a pickup truck, the flat surface in the back where you throw things is the bed. On a lathe, the bed is the pair of horizontal rails that join the headstock and the tailstock and over which the turned part is positioned. A wood lathe bed is illustrated with wood lathe. On a lathe bed, the rails are called the ways.

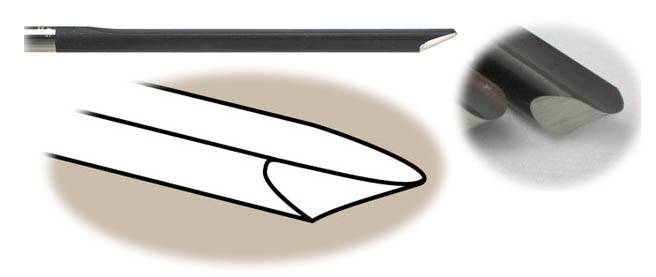

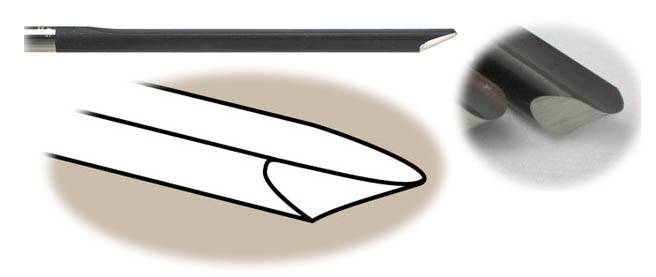

bedan --- A chisel-shaped lathe tool used for spindle turning in a similar way to a skew chisel, but very specifically for turning beads. The tool looks a lot like a beading and parting tool except that the cutting edge is on the top of the shank and there is a single face below the edge instead of two faces meeting in the middle as there is on the beading and parting tool. This tool is sometimes used as a parting tool for wide parts, but its primary use is as a skew for forming beads. Examples:

bed gap --- On a wood lathe there is often an extra deep area of the bed right next to the faceplate so that face turnings can be done with a larger swing than is available for spindleturning.

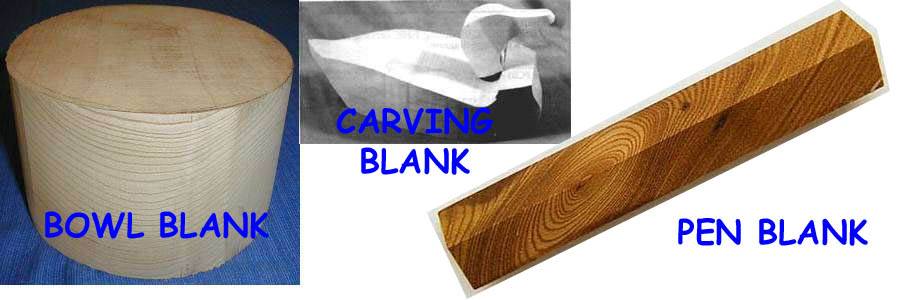

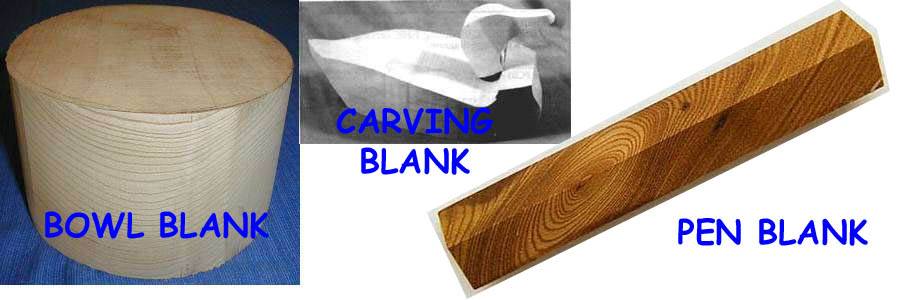

blank --- A piece of wood that has been brought into very roughly the shape and size of the product that it is intended to become. Most often refers to pieces that will subsequently be lathe turned or carved. Typically this will be a cylinder for a bowl turning, and a relatively slender, square cross sectioned piece for turning between centers. For example a "pen blank" is a small piece of wood about 3/4" x 3/4" x 5" or 6" long and the pen-maker puts it on a lathe and turns off everything that doesn't look like a pen. See bowl blank for pics. For carving, a blank might be a shape cut out roughly on a band saw for subsequent fine carving to final shape. Examples:

bowl --- In wood turning, this refers to a form in which, generally, the height is less than the diameter (but it could be a little more) and the rim is the largest diameter. If the rim curves back in towards the center, the object is more likely to be called an open form and if it curves back to a very small opening, the object is a hollow form. The range of shapes that are called bowls is QUITE large and the difference between "bowl" and vase is sometimes debatable. Compare/contrast to other lathe turnings. Examples:

bowlblank --- A piece of wood that is destined to be turned into a bowl on a lathe and that has been put into roughly the size and shape of the final bowl prior to turning. Examples:

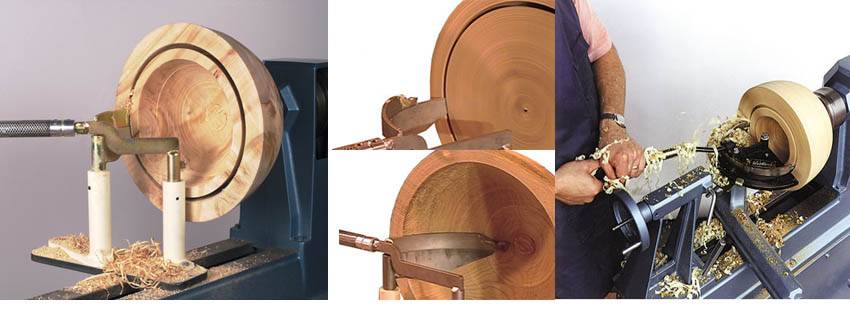

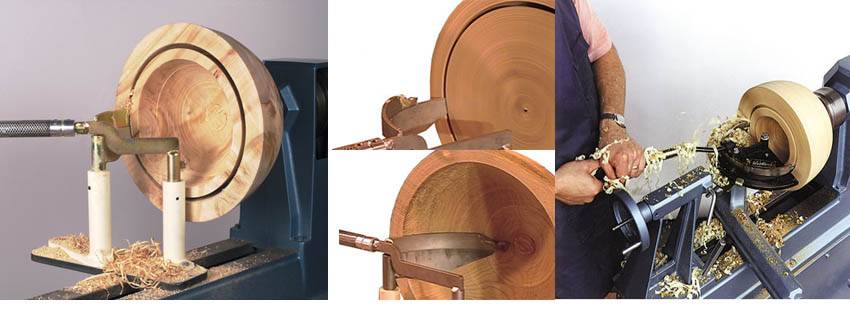

bowl coring system --- A cutting tool and tool rest that make up a system for coring out bowls in a way that allows for multiple, successively smaller, bowls to all be turned from the same bowl blank. The coring knife is a curved parting tool that cuts a bowl shape out of the front of a bigger bowl shape, and the process can be repeated multiple times depending on the size of the blank. Examples:

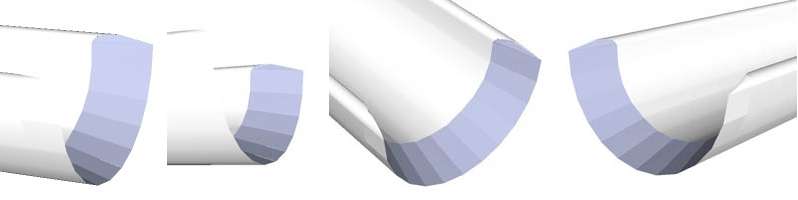

bowl gouge --- A type of lathe gouge specifically designed for face turning. Bowl gouges tend to be longer and heavier than spindle gouges and they also have a deeper flute. They are specifically designed to remove large amounts of wood from the curved sides of a turning bowl. The end bevel grind varies quite a bit on these gouges and there is a particular type of grind called a fingernail grind that makes the bowl gouge even more aggressive in removing material, and in fact many turners (myself included) much prefer the fingernail grind to a regular grind. However, the term "fingernail gouge" does not normally refer to a bowl gouge with a fingernail grind, but rather to a spindle gouge with a fingernail grind. See also lathe gouge shape comparison. The grind on bowl gouges will vary somewhat by manufacturer, even aside from the major differences between regular grind and fingernail grind. Also, there is more variety in the shape of the cannel on a bowl gouge than on a spindle gouge (where they tend to be circular arcs). Below are two sets of composite pics, the first with regular grind bowl gouges and the second with fingernail grind bowl gouges:

BOWL GOUGES WITH REGULAR GRIND

BOWL GOUGES WITH FINGERNAIL GRIND

bowl lathe --- A short bed, large swing wood lathe, often without a tailstock, that is used just for turning bowls.

bowl scraper --- A lathe tool; a variant on the round nose scraper in which the cutting edge is mostly on one side and continues along the body of the scraper (on that side) for an amount that varies by manufacturer, but which is more than what exists on a round nose scraper. The purpose is to provide a large cutting surface placed so that it is most useful when turning the insides of bowls. The "normal" bowl scraper is what is also known as an inboard bowl scraper, for reasons that are discussed with the term inboard turning. When turning the outsides of bowls, using outboard turning it is useful to have a tool where the cutting edge is on the opposite side, and that tool is the outboard bowl scraper. It should be noted, however, that many turners turn the outside of their bowls first, with the outside of the bowl pointing away from the headstock and then they remount and turn the inside; when using this technique, there is no need for an outboard scraper. Outboard bowl scrapers are not as widely available as regular bowl scrapers. Examples:

bowl steady --- synonymous with back steady

box --- In addition to having the normal English language meaning (e.g. jewelry box, cigar box), in wood turning this term is also used for round containers, turned on a lathe, that a non-woodworker would not normally think of as a "box" since the very terms "box" and "boxy" imply a rectangularity that is not present in what I designate, in this glossary, by a term that I like even though I have only rarely seen it used, and that is lathe box.

bull nosed center --- (aka bull-nose center or bullnose center) A cone center that has a truncated end. Unlike the cone center, which may be a live center or a dead center, the bull nosed center is always a live center. It is used in the tailstock to support hollow cylindrical objects, primarily pipes, and is used more in metal lathes than in wood lathes. The cone center's use is based on the tip, so the section behind the tip need not be particularly large, but the bull nosed center is meant to hold pipes of various diameter so is much larger. Examples:

cannel --- The hollowed out part of a gouge blade. The ground, sharpened end of the cannel is the cutting edge of the gouge. If the ground out portion is on the inside of the blade it is called in-cannel and if it is on the outside of the blade, it is called out-cannel. As a nominal rule, In-cannel blades are used for concave surfaces and in-cannel blades are used for convex surfaces but good wood turners make their own rules after experimenting with what works best for them.

captive hollowing tool --- An elaborate, articulate-arm, mechanism for doing precision lathe turning of deep hollow forms. Most (possibly all these days) come with an attachment that puts a laser beam on the outside of the turning form so that the wall thickness can be judged with great accuracy, thus allowing very uniform wall turning with no danger of making it too thin. These are expensive systems, but for those who do this kind of turning, I can see how they would be invaluable. Examples:

captive ring tool --- A lathe tool; A special scraper that is used to cut full, self-contained rings on spindles such that they are captive around the spindle and look like they had to have been put there by magic. The "captive ring tool" is not at all the same beast as the ring tool. Captive ring tools come in two forms, the first being a solid ground scraper and the second being a variation of the multi tip scraper. Examples:

catch --- In lathe turning, when the lathe tool digs into the wood and holds it instead of scraping or slicing it, and the lathe consequently hesitates or stops turning completely. Catches are the bane of novice turners and overly aggressive pros. Catches can cause nasty gouges in the workpiece and if the lathe tool is positioned with too much of it hanging out over the tool rest, a strong catch can break or bend the tool or grab it out of the operator's hand, any of which events would be considered a Bad Thing and likely to cause loud exclamations of words that we do not encourage our children to use.

Celtic grind --- synonymous with fingernail grind

centerline --- (1) On any tool that has rotational action, the centerline is the axis of rotation.

centers --- (1) On a lathe, the parts at each end of a spindle and that are pressed against it to hold it in place, thus the expression "turning between centers". See also cone center, dead center, drive center, live center and ring center. Centers, especially those that mount in a tailstock will usually be part of a Morse taper or other machine taper.

centers --- (2) The inner plies of a plywood panel. Some definitions specifically state that such use of the term implies that the grain of the centers runs parallel to the grain of the front and back plies but that definition restricts the term to only the one innermost ply and I have seen it used to mean all but the outer plies (that is, synonymous with core).

chatter --- (1)[noun] A rapid, and usually noisy, vibration of a workpiece due to interaction with a moving tool edge, or of the tool edge itself due to interaction with a workpiece. Chatter tends to be bad because it represents an uneven operation of a cutting tool, and it is not a happy sound for a woodworker since it means things are not going smoothly.

chatter --- (2)[noun] Speech emanating from one's spouse when one is trying to concentrate on a woodworking project. This is not a happy sound for a woodworker, because unless one changes concentration from the woodworking project to the chattering, things will not go smoothly later.

chatter tool --- A tool used on wood on a lathe to create a series of light gouges or dents around circular path. The tool may have various kinds of handles but the working part is a thin, fairly narrow, metal blade that is touched lightly to the wood and which develops harmonic vibration (called chatter thus creating a regular series of gouges/dents. The pattern thus obtained is called chatter work.

chatter work --- On a wood lathe, there is a technique for producing a decorative pattern by having a thin lathe tool called a chatter tool that is presented to the workpiece surface in such a way as to deliberately cause the tool to chatter harmonically to produce a wave-like pattern on the work surface. This effect is sometimes produced UNintentionally and has to be smoothed over. When this harmonic chatter is done deliberately, it is called chatter work or "harmonic chatter"; when done UNintentionally, it is generally just called "harmonic chatter" (and sometimes other names that should not be printed in a family magazine).

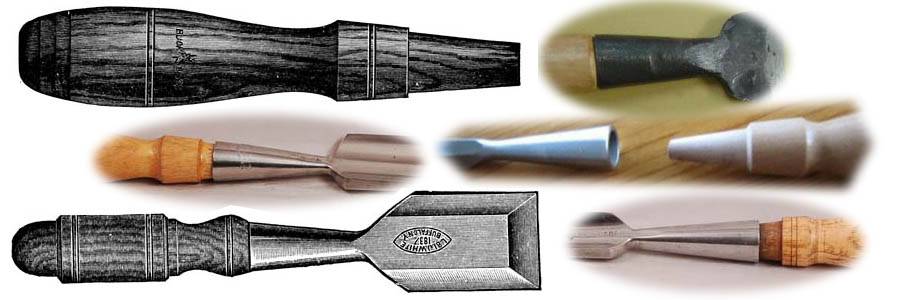

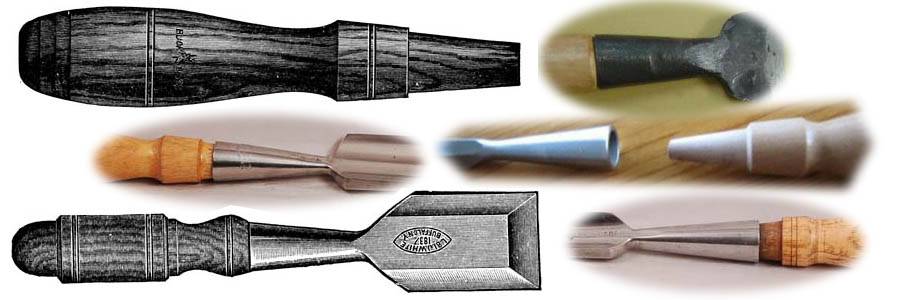

chisel --- A metal tool, usually steel, with a straight sharpened edge at one end and a handle on the other. It is used to chip, carve, engrave, turn, or otherwise cut into a solid material such as wood, stone, or metal. A chisel may be forced into the workpiece by hand or by blows of a carving mallet on the top of its handle or in the case of a lathe chisel, pushed into turning wood while being supported by a tool rest. Chisels come in an almost unlimited variety of sizes and shapes, depending on intended use. Although there are three fundamental types of chisels, there are numerous terms describing chisels and their attributes, so I have listed below a large number of such terms with links to their definitions. The three fundamental types of chisels, based on general use (not size or shape) are carving chisels, joinery chisels, and lathe chisels. The sister tool, gouges also come in carving and turning types but there are no joinery gouges. See also chisels vs gouges.

Fundamental chisel types:

carving chisel --- used for wood carving)

joinery chisel --- used for making/cleaning wood joints

turning chisel --- used in wood lathe turning

chisels vs gouges --- Although there is total sloppiness in the common usage of these terms, there IS a clear and cleanly defined technical distinction between chisels and gouges and it is simply that chisels always have cutting edges that are flat and gouges always have curved cutting edges. Both carving gouges and lathe gouges tend to be called chisels in common usage and it is absolutely normal to see a "chisel set" which contains gouges.

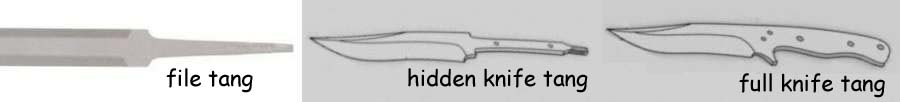

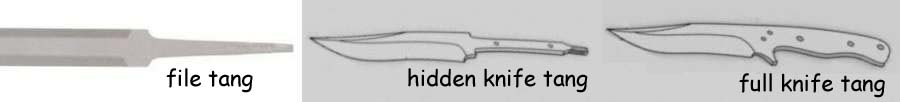

A chisel may have a "V" shaped pair of straight edges (typically at either 60 degrees or 90 degrees to each other), but if something has a "U" shaped cross section , no matter how deep or shallow, it should not (technically) be called a chisel, but is a gouge. Also, a chisel can have a curved cutting edge that is all in the same plane as the body of the tool. The amount of curve on a gouge's cutting edge is known as the sweep but there are no standards for measurements, so different manufacturers describe sweep differently and some care is needed when comparing tools from different manufacturers. Sweep is also known as "smile", although I have not often seen that terms used. When a gouge has a cylindrical barrel with a "U" shaped channel cut out of it, that channel is called the cannel. Both chisels and gouges are normally mounted on a wooden handle by way of a tang or a socket although in recent years, lathe gouges with metal handles have become popular. Despite the relatively high expense of these metal handles, they can be cost effective because they have set screws to allow them to be used with multiple blades (although only one at a time, of course).

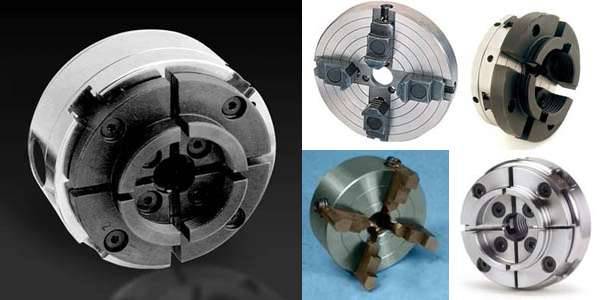

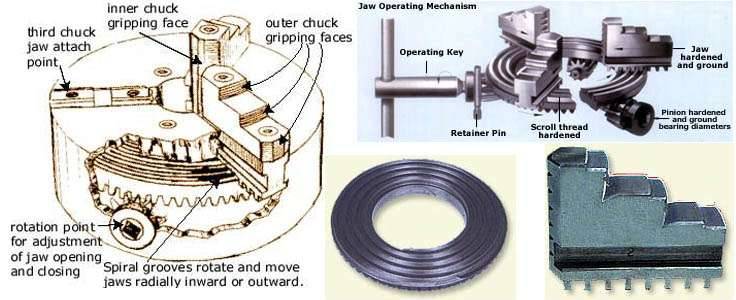

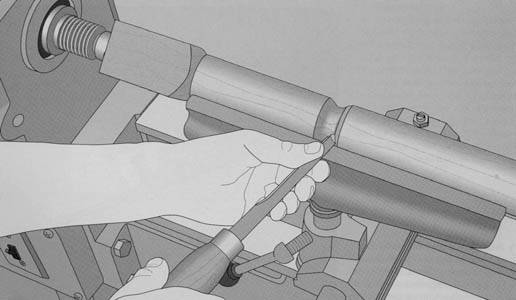

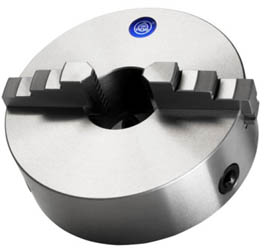

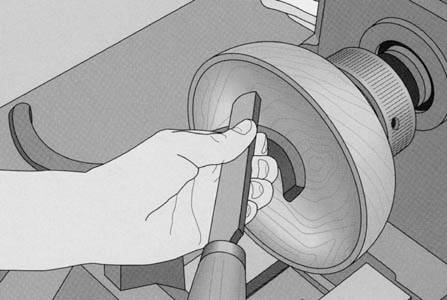

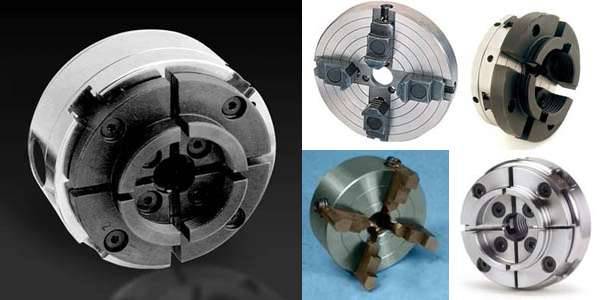

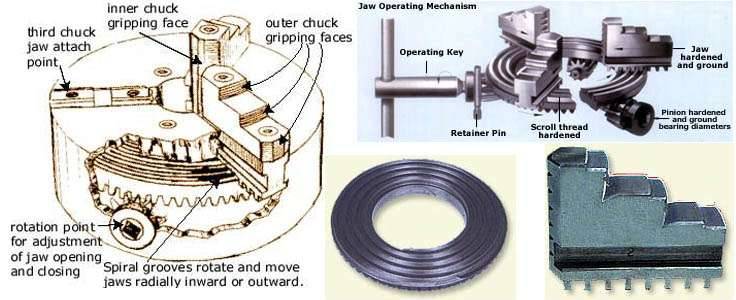

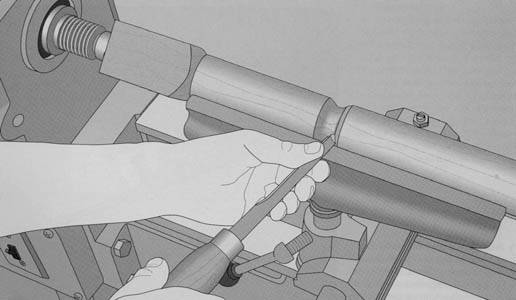

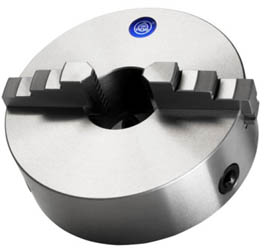

chuck --- A clamping device that holds a tool or the material being worked on in a machine with a rotating action such as a lathe or drill press. Chucks for lathes may be designed to hold a workpiece by either compressing around its base or expanding into an existing cavity and they may consist of a set of jaws or a set of arcs or even a single screw. Also, some lathe chucks do not hold the workpiece directly but rather hold a face plate to which the workpiece is attached. Drill press chucks always press in on whatever is being held, usually a cutting bit, not a workpiece, but sometimes workpieces are rotated in a drill press for various operations. Chucks are normally tightened with a chuck key but some chuck are "keyless" and work with by the user twisting the end of the chuck. Battery operated hand drills often have keyless chucks. Here are some examples of both drill chucks and lathe chucks:

DRILL CHUCKS:

LATHE CHUCKS:

chucking --- The process of mounting a workpiece in a chuck. The opposite is unchucking.

chuck key --- A metal rod, often bent in a "L" shape or with a cross-bar on one end, with grooves that mate into an area in a chuck and when turned cause the chuck to open and close. Examples:

clearance angle --- The angle between the bevel at the end of a tool (generally a chisel) and the surface of the workpiece to which the tool is being applied.

collet chuck --- (1) synonymous with collet

collet chuck --- (2) A homemade chuck for use on a wood lathe; it consists of a hollowed-out cylinder with splits cut out in the end and using a pipe clamp to tighten the end down around the workpiece. The name is rather obvious since it looks just like a collet. These are most often used for small turnings such as bottle stoppers. Examples:

compression chuck --- Another name for a four jaw chuck or a three jaw chuck when it is being used in a way that catches the outside of a rim of wood (e.g. on the bottom of a bowl) by compressing down onto it. Compare/contrast to expansion chuck.

cone center --- A lathe center that can be either a live center or a dead center. In either case, it has cone shaped point for use in the tailstock spindle of a wood lathe to support a spindle for turning. Generally used for light spindle work, where heavier work would use a cup center so as to have less chance of splitting the workpiece. Examples of both live and dead cone centers:

cone chuck --- synonymous with cone center, although it seems incorrect to me to call a center a chuck since a center just pushes against a workpiece whereas a chuck grabs it.

coring system --- see bowl coring system

corner scraper --- synonymous with spear point chisel

cove --- A semicircular, oval, or "U"-shaped concave depression running around the circumference of a spindle turning or across the face or edge of a flat piece of wood or along the length of a strip of molding or along the length of a spindle. Examples:

cup center --- A lathe center that can be either a live center or a dead center. In either case, it has a small point set in the middle of a ring. The point sticks out a little further than the edge of the ring and locates the center and then the ring presses into the surface of the spindle thus limiting the penetration of the point but providing strong support for spindle turning. This helps to prevent the splitting that can occur with a cone center and is particularly useful for built-up (laminated) spindles. While a dead cone center only makes contact right at the center of roation where the speed is low, there is relatively little chance of burning the wood, but the cup center make contact farther out so a dead cup center runs considerable risk of burning the wood. That doesn't matter to the final product, since the area of contact is destined to be turned off at some point, but who wants a stinky woodburning smell while turning? SO ... dead cup centers are rarely used these days, as witnessed by my inability to find recent examples for the pics. Examples of both live and dead cup centers:

cup chuck --- A cylindrical chuck for use on a lathe that has a cross section that looks like a pretty square letter "U" (or a steep-walled cup, thus the name) into which a workpiece can be pressed. Sometimes taken as synonymous with spigot chuck but a cup chuck can be quite shallow whereas a spigot chuck (jam chuck) is always relatively deep.

cut-off tool --- synonymous with parting tool

dead center --- [noun] A lathe center that sits in either the headstock spindle or the tailstock spindle of a lathe. In the headstock spindle, this would generally be a spur drive or a Steb drive but in the tailstock spindle, it might be a cone center or a cup center. The primary characteristic of the dead center is that it does not have any roller bearings. Compare/contrast to live center.

dead center --- [adjective] Exactly in the center

deep fluted gouge --- synonymous with bowl gouge; compare/contrast to shallow fluted gouge, which is synonymous with spindle gouge. That is, bowl gouges have a relatively deep flute and spindle gouges have a relatively shallow flute, thus the alternate names.

detail gouge --- This term is sometimes used as synonymous with "fingernail gouge", which is a a spindle gouge with a fingernail grind. However, there is a distinction that many manufacturers make, which is that the gouge they call a detail gouge has a more shallow cannel than a spindle gouge. The name "detail" comes from the fact that they are great for working on fine details in a spindle turnings. There is an even MORE shallow cannel version that is called a shallow detail gouge. See also lathe gouge shape comparison. The examples in the composite pic below include both spindle gouges with a fairly shallow flute and a fingernail grind, and also what are more appropriately called detail gouges because of their very shallow flute:

diamond parting tool --- A lathe tool; This is a variation on the standard parting tool in which the sides of the tool are expanded outward so that it has a diamond-shaped cross section which gives the tool extra rigidity. The shape also makes the tool usable in face turning moving directly in towards the headstock, which could not be done without the clearance this shape provides at the top and bottom of the shank. Examples:

diamond point chisel --- synonymous with spear point chisel

diamond point scraper --- synonymous with spear point chisel

diamond side cutting scraper --- see side cutting scraper

dish --- See lathe turnings.

donut chuck --- A homemade jig for finishing the bottom outside of bowls after all of the upper part, inside and outside, has been turned on a lathe. It consists of two sheets of plywood (other material could be used but plywood is highly recommended for these jigs), one solid to attach to the faceplate and the other with a hole in it for the bowl, and 3 or 4 bolts holding the two sheets together and parallel to each other in a way that captures the bowl, centered properly so that the bottom can be turned. That is, the face of the bowl goes flush against the faceplate piece of plywood and the other piece comes down over the bottom of the bowl, leaving enough bottom exposed to be turned, and the bolts then keep the bowl locked in place for turning. There are versions (see left-most example in the composit pic below) which are designed such that the "bottom" piece of plywood sits behind the faceplate. Examples:

dovetail scraper --- A lathe tool; a form of sidecutting scraper that is used to make a dovetail cut in the back side (base) of a bowl so that it will fit snugly into a similarly shaped surface on an expansion chuck. Examples:

drive center --- A lathe center that not only holds a spindle turning but also transfers the motor power through the headstock to the workpiece. There are two types and they are discussed individually in detail in this glossary. They are the spur drive and the Steb drive. Sometimes the term "drive center" is used to mean specifically the spur drive because before the invention of the Steb drive, the spur drive really was the only kind of drive center.

duplicating lathe --- A mechanical device that allows a lathe to make repeated identical copies of a turning by controlling the motion of the cutting tools.

duplicator --- In woodworking, this term usually means a duplicating lathe.

Ellsworth grind --- A variation on the fingernail grind as designed by professional turner / tool designer David Ellsworth. "Fingernail grain" is itself a term that can be applied to a very wide range of grind shapes and angles (although all of the same general form and the intracacies of that level of differences among lathe tool grinds is beyond the current scope of this glossary, so I'm not going to attempt to illustrate the Ellsworth grind other than to refer you to the fingernail grind.

enclosed form --- A term that is synonymous with open form, as weird as that sounds. I think the use is taken from the point of view of a bowl, from which point of view the item looks relatively closed, rather than from the point of view of a "hollow form" from which point of view it looks relatively open.

end grain turning --- Any turning in which the gouge cuts directly across the end grain of the wood. The problem with end grain turning is twofold. First, if your gouge isn't razor sharp you run the risk of crushing the end grain fibers rather than slicing them, and second, end grain turning, especially on really hard woods, dulls the gouge cutting edge very quickly compared to side grain or face grain turning.

end steady --- synonymous with tail steady

expansion chuck --- Another name for a four jaw chuck or a three jaw chuck when it is being used in a way that catches the inside of a rim of wood (e.g. on the bottom of a bowl) by expanding into it. This is often done with chuck surfaces that mate with an angled inside rim made with a dovetail scraper. Compare/contrast to compression chuck.

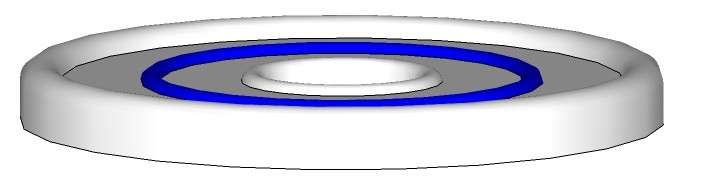

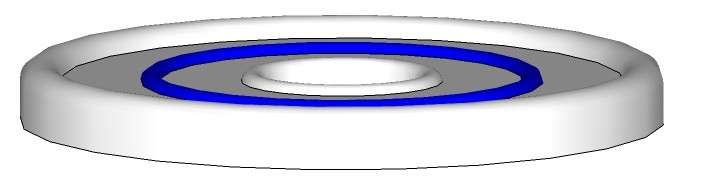

face bead --- A bead that is turned on the face of a face turning workpiece. For example, all three of the raised areas in the example below could be considered face beads, but the one in the middle of the three is unquestionably a face bead. Examples:

faceplate --- A metal disk with holes for mounting screws for a wooden piece (usually a bowl) that is to be turned on a lathe. The central part of the back of the faceplate either has a threaded shaft or other mounting mechanism that goes onto the lathe in place of a chuck. The number of screw holes for use in mounting the workpiece can vary from 3 up to a dozen or more and on some faceplates, the "holes" are long slots that allow for variable positioning of the mounting screws. Examples:

faceplate turning --- A type of face turning on a lathe where the object, most often a bowl, is attached to the headstock by way of a faceplate and the tailstock is not used at all. Unlike spindle turning, at least some of any faceplate turning will be directly against the end grain and this often requires extra sharp lathe tools so as to avoid crushing the end grain instead of slicing it. Compare/contrast to spindle turning. Example:

face turning --- A type of lathe turning where the object being turned is supported entirely on the headstock by either a faceplate (in which case, the type of turning may be called faceplate turning) or a chuck but in either case is not supported at all by the tailstock. Face turning is typically the turning of a bowl or vase, but could be any object. Unlike spindle turning, at least some of any face turning will be directly against the end grain and this often requires extra sharp gouges so as to avoid crushing the end grain instead of slicing it. Compare/contrast to spindle turning. For an illustration, see faceplate turning.

finger gouge --- synonymous with fingernail gouge

fingernail gouge --- Refers to a spindle gouge with a fingernail grind. These are also sometimes given the name "detail" gouge because they are great for working on fine details in a spindle turnings. Note that bowl gouges are also given a fingernail grind, but are NOT then called fingernail gouges.

fingernail grind --- Describes a particular end grinding shape used on bowl gouges and spindle gouges. It differs from a standard end grind in two ways; first, the angle of the grind along the bottom of the shank is more sharply back towards the handle and second, the grind along the sides of the shank is much more acute and long reaching, providing a much wider curved cutting edge than you get with a regular grind. The term is applied to a fairly wide range of angles and sweeps, all of this general shape. This grind is much preferred by many turners (myself include) because it supports a wider variety of turning techniques, but it IS correspondingly more challenging for the novice. Examples:

flat grind --- A flat tool grind that is caused by using the side of a grinding wheel or the face of a flat sharpening stone. Compare/contrast to hollow ground.

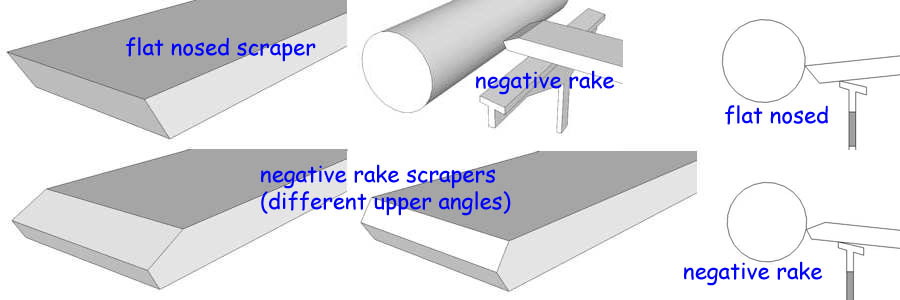

flat nose scraper --- A lathe scraper; This scraping tool has a cutting (scraping, actually) edge perpendicular to the shank and it is presented to the face of the workpiece parallel to the top of the tool rest, so that it smoothes out a flat area. Compare/contrast to round nose scraper. Examples:

flute --- (1) A deep channel cut in wood (or any other material), usually with a semi-circular bottom, but it could be oval. On a spindle, a cove that goes around the circumference is always called a cove but a cove that runs the length of the spindle is also called a flute.

flute --- (2) The cannel of a gouge or any recessed area of a cutting tool's cross-section that conveys chips away from a cutting edge as the tool rotates (or on a lathe tool, as the wood rotates against the tool). The flute may be straight, as it is in a tapered reamer, or it may be curved, as it is in a standard drill bit, but in any case it will follow the cutting edge. In lathe tools the flute/cannel runs the length of the shank (or sometimes only a part of the length) from the cutting edge back towards the handle.

flute --- (3) A out outward dent in a growth ring. See fluted.

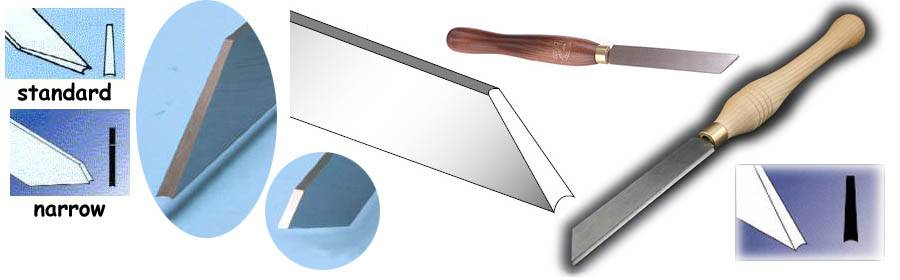

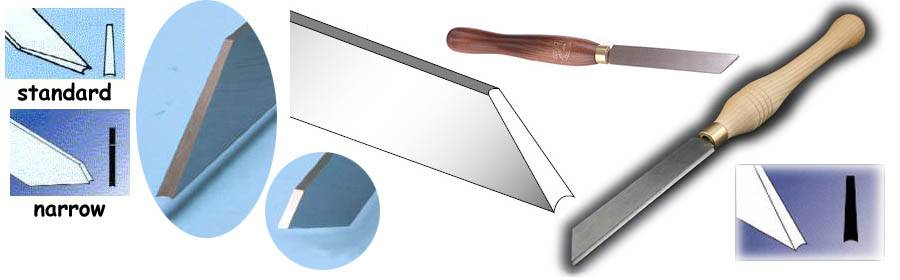

fluted parting tool --- A lathe tool; This is a variation on the standard parting tool and differs from that tool in two ways. First, it has a tapered shank and second, it has a fluted edge which gives it a more aggressive cut than the standard parting tool. It comes in two varieties, the first is the "standard" version with a flared shank and the second is the "narrow fluted parting tool" which has a shank that is straight up and down and narrow, giving a rectangular cross section with little rigidity. Examples of both types:

formed tool --- A lathe tool that has been ground to a particular shape for a special job because the shape is difficult to make with standard tools and/or because of a need to quickly reproduce a particular cut. An example of such a tool is the dovetail scraper.

four jaw chuck --- A very common, versatile, chuck for a wood lathe that has (surprise, surprise) 4 jaws, comes in a wide variety of styles, and takes several types of adaptors to hold various types of workpieces in various ways. The most common use for this chuck is to grab a raised rim on the bottom of a bowl, on the inside by expansion or on the outside by compression. When the jaws are grab by compression, the chuck is sometimes called a "compression chuck", and when the jaws grab by expansion, the chuck is sometimes called an "expansion chuck". The compression/expansion force is applied via a key, and the chuck may be a self centering chuck (i.e. a scroll chuck) or an independent jaw chuck. Examples:

gap --- (1) An opening between two pieces of wood. Usually, the implication is that there should not be such an opening. For example, gaps in the inner plies of plywood are not desirable. However, it is possible to have a situation where a gap is desirable, so the term does not automatically imply a bad thing.

gap --- (2) see bed gap

ghost --- see ghost outline

ghost outline --- When turning objects on a lathe, before the outer rim becomes completely round, there are projections at various places around the rim and these can be faintly seen at the edges of the turning workpiece; this is referred to as a ghost or ghost outline. Using the ghost can be very helpful in determining exactly how to attack the edge with the lathe tool to continue the rounding of the edge but without being overly aggressive and causing chip-out while doing an interrupted cut.

glue block --- A flat piece of wood that is glued directly (or indirectly with a Kraft paper separator) to the back of a workpiece that is going to be face turned and is then itself mounted on a faceplate; the glue block avoids getting screw holes in the workpiece.

goblet --- A somewhat vague term, which I have seen used to describe turned objects that have the shape of anything from a wine glass (sides pretty much straight up after curving away from the stem) to what I think of as a goblet shape, which is more like a cognac snifter. Compare/contrast to other lathe turnings. Examples:

going --- As regards woodworking, this term refers to the depth of one stair tread, not measured on the tread itself but rather horizontally from one riser to the next riser, so if the tread projects out over the riser, that projection is not counted as part of the going. The term is also used to refer to the combined depth of a flight of stairs as measured from the face of the first riser, horizontally, to the face of the last riser. Also called the "run". Compare/contrast to rise.

gouge --- [verb] To cut wood with the kind of tool described below, and by extension, to make any sort of channel-like cut into wood, whether deliberately or by accident. Accidental gouges are unhappy occurances for a turner, as they can cause considerable rework to remove and can even ruin a piece under some circumstances.

gouge --- [noun] A sharp-wedge-edged tool with a curved cutting edge. Gouges fall into two distinct types, lathe (or "turning") gouges and carving gouges. The sister tool, the chisel, is a straight sharp-wedge-edged tool. It is the straight vs curved edge that makes the distinction between the two. Chisels also come in those two flavors, but also has a third that does not exist in gouges and that is the joinery chisel. See also chisels vs gouges.

grind --- [verb] In regards to woodworking, this refers to the action of removing some of the surface of a metal object by an abrading action, generally by a grinding wheel or sharpening stone. See also grind / hone / polish.

grind --- [noun] The shape of a cross section of a blade showing the shape of the grinding edge. For example, a tooth on a a circular saw blade is said to have a "flat tooth grind" if the top (cutting) edge of the tooth is perpendicular to the body of the blade and a fingernail grind is a particular form of grind on a lathe tool

Grind related terms:

grind angle --- The angle from the shaft of a tool to the bevel on the working edge.

headstock --- On a lathe, this is the part that holds the material to be turned (or hold it on one end in the case of spindle turnings) and attaches to a motor that powers the rotation. The headstock may incorporate the motor directly but more often the motor is below or to the side and attaches to the headstock arbor via a V belt. Illustrated with wood lathe.

high speed steel --- [HSS] High speed steel; a grade of steel about 6 times harder than carbon steel and able to retain a cutting edge 5 to 10 times longer than carbon steel. HSS tools should be ground on a 'white' (aluminum oxide) grinding wheel.

hollow form --- A term wood turners use to describe a turned container that has only a small opening through which the turning tools can be inserted while the turning the inside. It is difficult to turn such items, and particularly difficult to get the wall thickness consistent, because the turner is working blind. There are elaborate (and sometimes expensive) mechanical contraptions (see captive hollowing tool) that assist in the turning of the inside of such items. The term "hollow form" is somewhat vague and you might see identical forms referred to by one turner as a hollow form and by another as a vessel, a vase, or an urn. I have attempted to clarify the distinctions with a description of the various lathe turnings. Examples:

hollow grind --- synonymous with hollow ground

hollowing tool --- A lathe tool; this is a somewhat generic name for any number of different lathe tools that all have the same purpose, namely that of hollowing out the inside of a turned vessel (e.g. a vase). There are versions that have replaceable tips and numerous differently shaped solid tip versions. When the shank has a bend in it to facilitate reaching behind the inside of the lip of the vessel, the tool is sometimes called a swan neck hollowing tool. For very elaborate versions with articulated arms, see captive hollowing tool. Here are some examples:

inboard --- see inboard turning

inboard bowl scraper --- synonymous with bowl scraper. That is, the "normal" bowl scraper is what is otherwise also called an "inboard bowl scraper" to distinguish it from the similar outboard bowl scraper. See also inboard turning.

inboard turning --- When an object is turned on a lathe for face turning the rotation is normally counterclockwise as seen looking into the headstock, so the tool rest is placed on the left side of the object being turned and the left side of the lathe tool cuts into the object as it moves down past the tool rest. This is called inboard turning. When it is necessary to turn the rear of an object that is mounted for face turning, then the object is moving in a clockwise direction as you look at it from the rear, and the cutting edge of the lathe tool has to be on the right side of the tool, for what is called outboard turning. Some lathe tools (e.g. bowl gouges), this doesn't matter because the tools have cutting edges on both sides and so can be used either way. Some tools however (e.g. bowl scrapers, have the cutting edge on the side and there have to be separate versions for inboard and outboard turning. Compare/contrast to outboard turning.

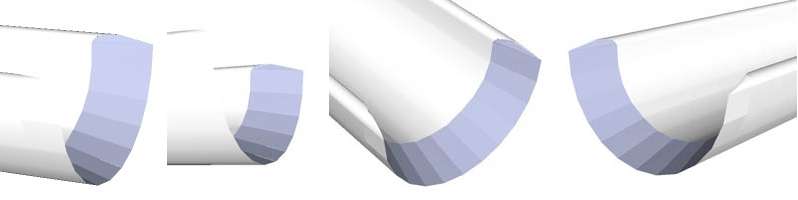

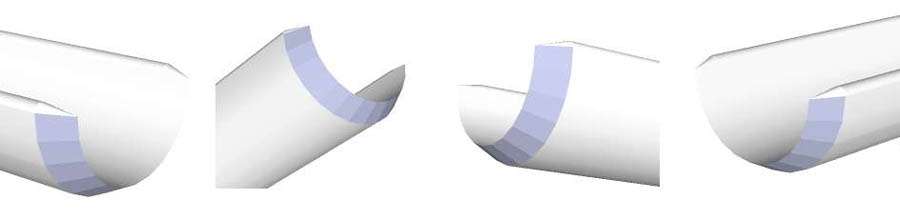

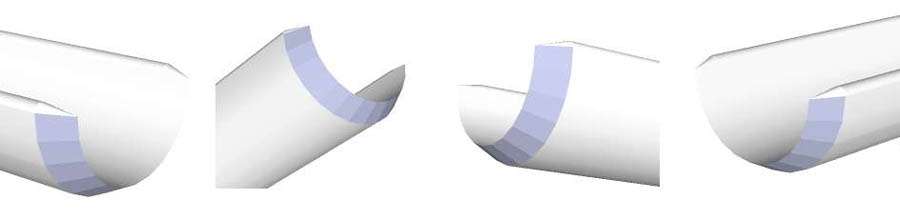

in-cannel --- The characteristic of a gouge that has its ground and sharpened end section on the inside of the blade. In-cannel blades are used to carve or turn concave surfaces. Compare/contrast to out-cannel. Examples (actually these are all the same gouge drawing, just seen from different angles):

independent jaw chuck --- A type of chuck where each jaw is controlled independently rather than all being controlled together as in a scroll chuck. It can be a 3 jaw or 4 jaw chuck (or even more). There are three advantages to this type of chuck over a selfcentering chuck such as the scroll chuck. The first is that the centering can be fine tuned to minimize runout, the second is that it can hold irregular shaped objects, and the third is that it allows for off-center turning. The disadvantage of this type of chuck is that it HAS to be adjusted for centering, which makes it more time consuming to use than a self centering chuck. When looking at a chuck it is immediately apparent whether it is a scroll chuck or an independent jaw chuck because unlike the scroll chuck which has only one adjustment hole, the independent jaw chuck has an adjustment hole with every jaw. Examples:

index head --- synonymous with index plate

index plate --- A plate used to lock a tool's drive-shaft into a series of pre-set regular positions. An index plate on a lathe, for example, provides a way to hold a spindle in several regularly-spaced positions to allow a lengthwise operation to be performed on it from the top or side.

inset bead --- A bead which is surrounded by wood that is more or less flush with the top of the bead. See the term bead for illustrations. Compare/contrast to standing bead.

interrupted cut --- The action of a lathe tool when it is cutting a non-yet-round object on a lathe; the tool is cutting wood during some of the workpiece's revolution but just sitting in the air for part of the revolution. Tools are harder to control during interrupted cuts than in full cut work, and care must be taken during interrupted cuts to avoid causing chip-out.

Irish grind --- synonymous with fingernail grind

Jacob's chuck --- A particular type of drill bit chuck which can also be held in the headstock or tailstock of a lathe. This is a little like "kleenex" --- it's a word that started out as a proprietary name but is now used as pretty much synonymous with "drill bit chuck". It can also be used to hold a small workpiece, instead of a drill bit, so that the workpiece will rotate in the lathe or drill press. Examples:

jam chuck --- sometimes synonymous with spigot chuck, sometimes synonymous with cup chuck.

ladyfinger gouge --- synonymous with spindle gouge

lathe --- see wood lathe (there are metal lathes too, but this is, after all, a glossary about wood, not metal).

lathe box --- This is a rarely used term that distinguishes round "boxes" from rectangular boxes. In normal English, "box" carries a connotation of "rectangular" whereas in wood turning, it does not, since round "boxes" turned on a lathe are just called boxes (which is why I say that the term "lathe box" is rare). Anyway, a lathe turned box is a turned container with upper and lower sections. The parts often have their outer surfaces turned first as a single unit, then they are separated (parted) using a parting tool and their insides are hollowed out separately on the lathe with the rims turned in a way to make the upper part be a form-fitting top to the lower part. Lathe boxes tend to have sides that are straight up and down as opposed to the more curved form of other type of lathe turnings. Compare/contrast to other lathe turnings. Examples:

lathe center --- Any of several devices that are used to support and/or drive work in or from the headstock or tailstock of a wood lathe. There are a couple of primariy characterists of lathe centers. First, they are either drive centers, which help transfer the motor power to the workpiece to make it turn, or support centers, which act only as a support for the workpiece. Drive centers go in the headstock and support centers go in the tailstock. Second, tailstock support centers may be "live" or "dead". live centers have ball bearings and turn with the workpiece whereas dead centers are locked in place and do not turn with the workpiece. The various types are:

- headstock drive centers

- tailstock support centers

lathe check --- The condition of the underside of veneer sheets as they come off of a veneer lathe. This is described in some detail with the term loose.

lathe chisel --- A chisel used in turning on a wood lathe. In colloquial use, the term includes tools that are technically lathe gouges and includes most of the tools shown in this glossary that are listed with the term lathetools. Lathe chisels tend to have longer handles than other chisels because they have to provide leverage against the force of the turning wood into which they are inserted.

lathe chuck --- see chuck

lathe gouge --- A lathe tool; a sharp, curved edge cutting tool with a an oval or cylindrical barrel. The barrel has a 'U' shaped portion (sometimes a "V" shaped portion) called the cannel, or the flute, removed from its upper section, sometimes all along the length, sometimes only along the first few inches back from the cutting tip. The edge is sharpened and honed and the gouge is used with the resulting sharp bevel cutting into the surface of wood revolving on a lathe. There are three main types of lathe gouges. (1) The roughing gouge, which is used, as the name suggests, to rapidly remove large portions of wood. (2) The spindle gouge, also called a "shallow fluted gouge", which is used primarily to do spindle turnings. (3) The bowl gouge, also called a "deep fluted gouge", which is used for face turnings.

Despite those designations for "typical" use, bowl gouges can be used for spindle turning and spindle gouges can be used on face turning, although in both cases this is often not a good idea. The lengths of lathe gouges vary quite a bit, from as little as 6 or 8 inches for turning very small objects on a mini-lathe, up to 2 feet long, or even more, for doing large turnings. The long handles are to provide leverage so that the turning wood doesn't grab the end of the gouge and jerk it out of the operator's hand, and the bigger the turning, the longer the handle needs to be to provide good leverage. The distance from the toolrest to the workpiece is also a large factor in the leverage. Bowl gouges tend to be longer and heavier than spindle gouges and they have a deeper flute/cannel. See also lathe scraper, carving gouge, and lathe gouge shape comparison

lathe scraper --- A lathe tool; a flat piece of steel with a rectangular cross section . There is a handle on one end and a flat or curved edge on the other end that is beveled and ground to a cutting edge. The cutting edge is used in a scraping action when working on a turning in a wood lathe. There are several different types of lathe scrapers, all of which are pointed to in the term lathe tools, but the two primary types are the round nosed scraper and the flat nosed scraper.

lathe steady --- synonymous with spindle steady

lathe tools --- This is a bit of a misnomer, albeit a widely used one. "Lathe tools", to be completely correct, would include tool rests, chucks, gouges, chisels and possibly some other tools, but the term is actually used fairly widely to refer just to the CUTTING tools used with lathe turning, and that's how I use it here. Those cutting tools include occasional specialty tools other than those listed below, but this list covers all normal lathe tools and the terms associated with them, and each points to a separate definition, most with illustrations. I have also included some terms that are not tools (e.g. fingernail grind) but which help explain the tools and their uses

lathe turning --- [verb phrase] To use a lathe to turn an object, via either spindle turning or face turning using a lathe tool.

lathe turning --- [noun] An item turned on a lathe. There are numerous shapes, and there is no central authority to provide exact definitions of the terms used to describe them, and turners are a clever crew, always creating variations that defy strict definition, but I think most turners would pretty much agree with the following more or less, maybe, sort of, with caveats, if they are not in a cantankerous mood. Also, please note that for some of these, the term as used by woodworkers may not correspond exactly to the sense that the word has in normal English usage; I am only concerned with how the terms are used by woodworkers.

Below this set of definitions is a composite drawing showing a single sample shape of each many of the forms. The terms themselves are linked to a more extensive definition where there are generally composite pics of numerous examples of the corresponding form.

- bowl --- Generally, the height is less than the diameter (but it could be a little more) and the rim is the largest diameter. If the rim curves back in towards the center, the object is more likely to be called an "open form" and if it curves back to a very small opening, the object is a "hollow form". The range of shapes that are called bowls is QUITE large and the difference between "bowl" and "vase" is sometimes debatable.

- box --- A more-or-less "pot"-shaped turning that has a lid which fits fairly snugly, often VERY snugly. Typically, "boxes" are fairly small in diameter (over 6 to 8 inches would be rare) but there is nothing in the definition that requires them to be, although bigger ones tend to be called "lidded vessels", as do ones that differ significantly from the "pot" shape. "Boxes" are sometimes turned with wings in which case they are often more curved than normal "boxes" (see "winged box").

- chalice --- A goblet or pedestal bowl intended to hold a drink. I don't list/show this separately in this glossary because I rarely see it used with wooden objects and I feel that it is something of an affectation when it IS used since "chalice" more normally designates an ornately decorated metal object.

- dish --- This is not a term I have often encountered in wood turning. It seems to be a shallow "bowl" or a deep "platter", where the height is less than half the diameter and the whole thing is modest in diameter (if the diameter is large, it's more likely to be called a "platter"), but I have seen this so seldom that I'm not including it as a separate term outside this list.

- enclosed form --- A term that is synonymous with "open form", as weird as that sounds. I think the use is taken from the point of view of a bowl, from which point of view the item looks relatively closed, rather than from the point of view of a "hollow form" from which point of view it looks relatively open.

- goblet --- A somewhat vague term, which I have seen used to describe turned objects that have the shape of anything from a wine glass (sides pretty much straight up after curving away from the stem) to what I think of as a goblet shape, which is more like a cognac snifter.

- hollow form --- Has an opening that is significantly less than the maximum diameter. Generally the side will curve out and then back in, not be straight up and down. If the opening is fairly large, the object is more likely to be called an "open form". The difference between "hollow form" and "vase" is often non-existent and the decision on which term to use can be arbitrary

- knuckle buster --- This is a humorous reference to the fact that when turning items with deep wings (see "winged bowl" and "winged box") the wings act like propellers and the careless turner, who will not find it even REMOTELY amusing, can get the dickens smacked out of his/her fingers/knuckles.

- lidded bowl --- Sometimes synonymous with "box", but if the object is quite oval and has a lid, then many turners will call it a "lidded bowl" instead.

- lidded vessel --- Generally, an "open form" (but it could be a "vase" shaped turning) but with a lid. Lidded vessels tend to be bigger than "boxes" and have more curve in the sides and the lid usually is slightly loose as opposed to the close-fitting lid of a "box". A tall, relatively slim "lidded vessel" is likely to be called an "urn", especially if it has a pedestal or foot on the bottom. NOTE: many turners do not designate much of ANYTHING as a "lidded vessel", preferring to call the item whatever it would be called without the lid. Thus an "open form" with a lid is often just called an "open form", not a "lidded vessel".

- natural edge --- A turned item, most often a "bowl" or a "vase", that still has the bark from the tree on its rim or at least has the raw area where the bark used to be.

- open form --- The opening is larger than the base but significantly smaller than the maximum diameter. If the opening is really small, it's a "hollow form" and whatEVER the size of the opening, it might well be called a "vase" depending on which side of the bed the turner got out on that morning.

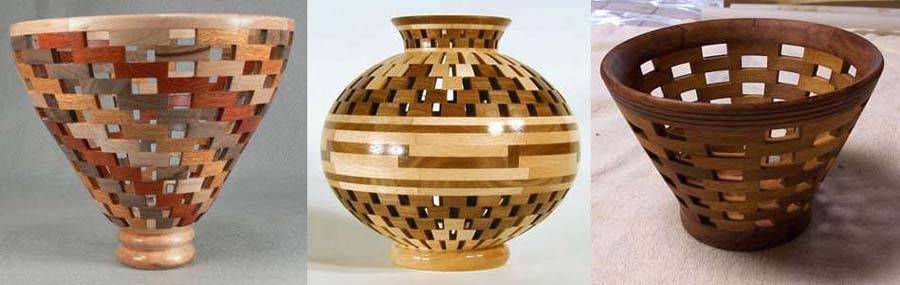

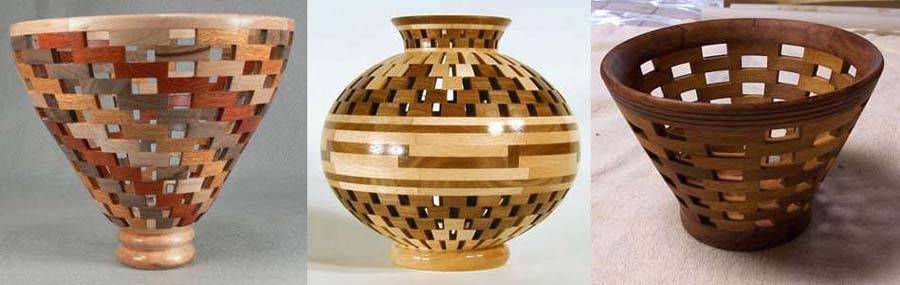

- open segmented bowl --- A "segmented bowl" that has empty spaces among the pieces.

- pedestal bowl --- A "bowl" that sits on top of a shorter turning designated a "pedestal". The pedestal COULD be turned from the same integral piece of wood, but often is turned from a different wood glued to the upper "bowl" portion.

- platter --- A very shallow, flat "bowl", with a diameter significantly larger than the height. Anything more than a couple of inches high is not likely to be called a "platter" and even that is high unless the turning is a couple of feet in diameter.

- pot --- The height and diameter are approximately the same, opening is pretty much equal to the diameter, sides are straight up. Like a standard kitchen cooking pot, this item is pretty much square in cross section, but unlike a cooking pot, it has no lid (if it had a lid, it would be called a "box".

- segmented bowl --- A "bowl" (and actually some of the other forms listed here are also done in segmented form) that is made up of glued-up piece of wood that are usually from at least a few different species and arranged in a geometric pattern. If there are empty spaces among the pieces, it is an "open segmented bowl".

- spindle --- long and skinny and not hollow (a table leg is a "spindle")

- urn --- A turning that is "vase"-like in proportion but with a smaller opening, like a "hollow form", and with a snug lid. The distinction between "urn" and "lidded vessel" is sometimes debatable. "Urns" typically have a "pedestal" or "foot" at the bottom. Like normal English usage, "urn" MAY mean a cylindrical container that holds cremated ashes.

- vase --- The height is more than the maximum diameter (often quite a bit more) and the opening is anything from the maximum diameter to a little less than the maximum diameter. If the opening is significantly less than the maximum diameter, it's usually called a "hollow form" but usage of these terms varies considerably. A slim vase with a top would be an "urn". The difference between "bowl" and "vase" is sometimes debatable and the difference between "urn" and "vase" is not debatable only because an "urn" has a lid and a vase doesn't.

- vessel --- A term that is used for damned near anything in this list; too vague for me to try to pin it down any further.

- winged bowl --- there are two types of bowls that are called "winged". The first is a bowl with "wings" that flow from the upper rim back downwards. Such drooping drooping wings may stop short of the bottom of the bowl or they may go down so far that the bowl is supported by the tips of the wings rather than the bottom of the cavity part of the bowl and when this is the case, the bowl is called a "lifted bowl"? or "raised bowl"? (or something like that --- I need some help here.). The second type is a bowl with a flat portion extending out from the top, or near the top, of the bowl. This is often done with burls. "winged bowls" are sometimes tuned in a way that allows them to be given tops, in which case they are called "winged boxes".

- winged box --- A "box" with "wings" that flow from the upper rim back downwards, or sometimes straight out. Downward drooping wings may stop short of the bottom of the box or they may go down so far that the box is supported by the tips of the wings rather than the bottom of the cavity part of the box and when this is the case, the box is called a "lifted bowl"? or "raised bowl"? or something like that and the "box" is often turned with an underside that is more round that would be the case on a normal "box".

RELATED TERMS:

- art --- A turned item with a high price.

- craft --- A turned item with a medium price.

- junk --- A partially turned item currently in flight across the shop ("Uh, Houston, we have a problem!")

SAMPLE FORMS (intended to be at least vaguely representative of the various shapes):

lidded bowl --- Sometimes synonymous with box, but if the object is quite oval and has a lid, then many turners will call it a "lidded bowl" instead. Compare/contrast to other lathe turnings.

lidded vessel --- In wood turning, this generally refers to an open form (but it could be a vase-shaped turning) but with a lid. Lidded vessels tend to be bigger than boxes and have more curve in the sides and the lid usually is slightly loose as opposed to the close-fitting lid of a "box". A tall, relatively slim "lidded vessel" is likely to be called an urn. Compare/contrast to other lathe turnings. Examples:

live center --- A lathe center which fits in a tailstock spindle and has ball bearings so that the part that comes into contact with the workpiece revolves with it. This might be, for example, a cone center or a cup center. Compare/contrast to dead center.

Longworth chuck --- A very simple, clever design for a homemade jig that acts as a bowl chuck for turning the bottom of bowls which have already had all of their upper surfaces (inside and out) turned. It consists of a pair of plywood (or other material) circles with crossing arcs in which you put bolts with rubber covers to protect the wood. There are instructions on the Internet for making them. Examples:

multijaw chuck --- A lathe chuck with more than 4 jaws.

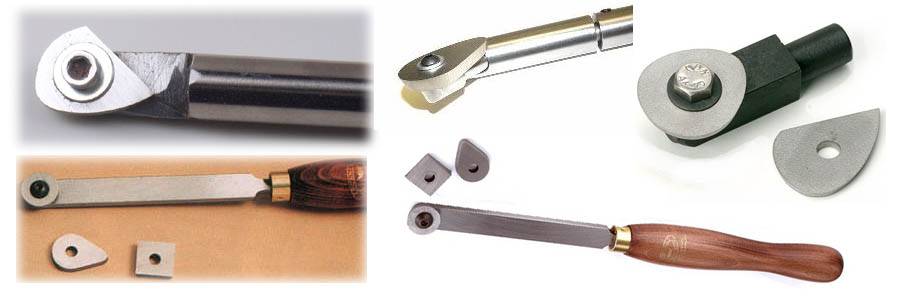

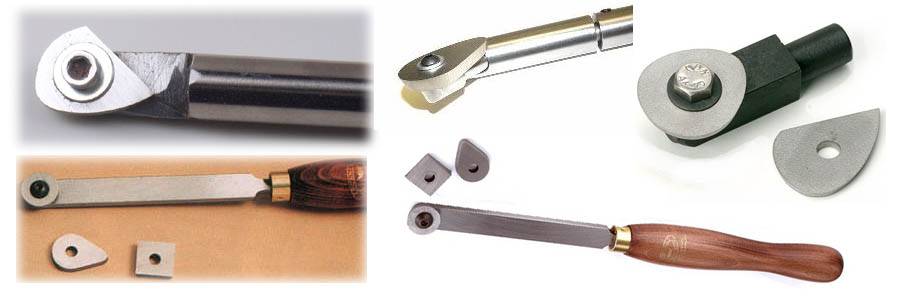

multi-tip scraper --- A lathe tool that has a removable tip that can be easily replaced when dull and/or with differently shaped tips for different uses. The tips are typically high speed steel or even carbide. Numerous manufacturers make various versions of these. Examples:

narrow fluted parting tool --- see fluted parting tool

natural edge --- An unfinished edge of a wooden object that retains the outer portion of the tree; a term most often used in describing the lip of a turned bowl in which the natural outer edge of the tree, often (but not necessarily) including the bark, is left untouched. Examples:

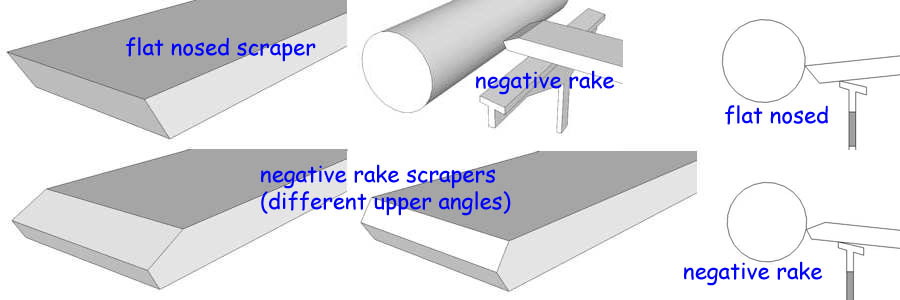

negative rake scraper --- A lathe tool that is a normal flat nose scraper with part of the top ground off so that both the top and bottom come off the shank at an angle. This reduces the "grab" of the scraper but the main characteristic is that it reduces the amount of material removed, and is thus very much a finishing tool, and would not be at all effective for hogging. It also allows the handle to be below the burr instead of above it, which some turners feel gives better control for fine finish turning. At the time of this writing, I have it on anecdotal information that there are not yet any vendors producing negative rake scrapers, so turners make their own by grinding off a large bevel on the top side. These tools are ideal for finishing scrapes on very hard wood and have been used for centuries by luthiers, who apparently make their own. A similar effect can be had by turning a skew chisel flat on its side and using it as a scraper, but skew chisels have a much sharper edge and are thus less amenable to a stable burr. Examples:

offset turning --- Turning objects on a lathe in a way such that for some portion of the length of the workpiece while turning, the center line of the object is NOT in line with the centerline of the lathe. One or both ends of the object are positioned such that their center is offset from the turning center of the center or chuck. Think of the crankshaft of a car. In woodworking, this is done for decorative effects.

Oland tool --- A homemade lathe tool designed by Knut Oland, with construction instructions available on the internet. it is a multitip scraper. It consists of a steel rod drilled out at the end to accept a machine lathe bit and with whatever kind of handle you choose to put on it (I've seen some with masking tape as the handle). It's inexpensive and fairly easy to make and by all reports makes an excellent turning tool and it has the advantage that you can replace the tip. Examples:

open form --- A wood turning item that has an opening larger than the base but significantly smaller than the maximum diameter. If the opening is really small, it's a hollow form. Compare/contrast to other lathe turnings. Examples:

open segmented bowl --- A type of segmented bowl that has empty spaces among the pieces; generally these are regularly spaced but some designs have them distributed irregularly. Examples:

outboard --- see outboard turning

outboard bowl scraper --- See full discussion give with the term bowl scraper. Examples:

outboard turning --- Face turning which is carried out on an extension of the drive-shaft on the left-hand side of the headstock, ie the opposite side to the bed. Some lathes have headstocks that swivel around away from the bed, thus allowing outboard turning to be done using the same spindle as inboard turning, and some simply mount the faceplate or chuck on the opposite site of the headstock, away from the bed. In that case, then relative to the turner the workpiece will revolve in the opposite direction as compared with turning over the bed; as a consequence the drive spindle and attachments (e.g. chuck or faceplate) require reverse threads. Outboard turning in those cases where the workpiece goes in the opposite direction from normal requires tool use on the opposite side of the workpiece, and some tools (e.g. outboard bowl scraper) have special versions for that use. Other tools (e.g. bowl gouge are symmetrical and can be used for inboard or outboard turning. Compare/contrast to inboard turning.

out-cannel --- The characteristic of a gouge that has its ground and sharpened end section on the outside of the blade. Out-cannel blades are used to carve or turn convex surfaces. Compare/contrast to in-cannel. Examples (actually these are all the same gouge drawing, just seen from different angles):

oval skew chisel --- A skew chisel that has an oval cross section taken perpendicular to the length of the chisel. The point of having the oval sides is that this makes it easier to rotate the tool on the tool rest for variable slicing angles as it is moved over a variable workpiece surface. For an extreme example of this, see the round skew chisel Examples:

paper joint --- Despite containing the word "joint", this is not a joinery term but rather a description of the use of paper (generally Kraft paper as a separator when gluing a glue block to a workpiece for face turning so that the glue block gets the screws from the faceplate rather than having them go into the workpiece. Paper joints are also sometimes used in spindle turning when it is desired to turn a spindle that is actually two or four sections glued up to be turned together before being applied separately. The paper joint makes it easy to separate the parts of the spindle once it has been turned.

parting --- [verb] In lathe turning, the use of a parting tool to separate a spindle turning into two parts, typically to either (1) cut off the waste portion at the end of a turning or (2) so that the parts can serve as the upper and lower halves of lathe boxes. Parting can also describe the separation of a face turning from the faceplate.

parting tool --- A lathe tool that is used to separate a spindle turning into two parts, typically to either (1) cut the work piece off from the waste portion at the end of a turning or (2) so that the parts can serve as the upper and lower halves of lathe boxes. There are four flavors of the tool, all with the same fundamental purpose, as follows:

pattern stick --- A thin, flat piece of wood on which is cut (with a scroll saw or fret saw) the outline of what a spindle turning is supposed to look like. That is, the silhouette of the finished turning should have the exact same contour as the edge of the pattern stick. This is particularly useful when making multiple identical copies of a turning. The pattern stick can be held right up against the turning to judge how high or deep to make beads and coves and other turning features. There is a similar, but less extensive tool called a story stick.

pedestal bowl --- A bowl that sits on top of a shorter turning designated a "pedestal" or "foot". The pedestal COULD be turned from the same integral piece of wood, but often is turned from a different wood glued to the upper "bowl" portion. Compare/contrast to other lathe turnings. Examples:

penblank --- A piece of wood that is destined to be turned into a pen on a lathe. Usually about 3/4" x 3/4" x 6" and made of exotic wood.

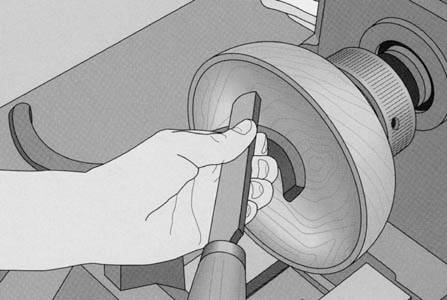

planing cut --- The cut made by a skew chisel on a wood lathe when it is used in its "standard" way with the edge at about 45 degrees to the edge of the turning spindle just above the the centerline. The cut made is very similar to that made by a hand plane, thus the name.

platter --- A very shallow, flat bowl, with a diameter significantly larger than the height. Anything more than a couple of inches high is not likely to be called a "platter" and even that is high unless the turning is a couple of feet in diameter. Compare/contrast to other lathe turnings. Examples:

plunge cut --- In lathe turning, pushing the lathe tool straight into the wood. Compare/contrast to sweep cut.

pole lathe --- An old-style human-powered lathe used for spindle turning green wood. The operator pushes a treadle down with his foot and this bends a long springy pole that is attached to the treadle by a rope and it is the spring action of the pole that returns the treadle to the up position ready for the next downward push from by the operator. Such lathes require different style tools than a powered lathe. They have been in use for thousands of years but are today a very rare hobby tool in the industrialized countries, not used commercially since about WWII.

pot --- A turned item in which the height and diameter are approximately the same, the opening is pretty much equal to the diameter, and the sides are straight up. Like a standard kitchen cooking pot, this item is pretty much square in cross section, but unlike a cooking pot, it has no lid (if it had a lid, it would be called a box. See lathe turnings for an illustration of the shape and compare/contrast to the other lathe turnings shown there.

precision combination chuck --- A once-popular proprietary chuck with attachments which can perform many of the functions performed by other chucks because it includes both expanding or contracting collets. Modern scroll chucks do pretty much the same things.

pressure chucking --- The process of pushing a live center on a tailstock onto a piece that is pressed up against a faceplate on the headstock so that the workpiece is held in place by the pressure rather than being held by a chuck. This has the advantage of very quick chucking and unchucking of the workpiece, but the disadvantage of being it being more difficult to get good centering on the workpiece.

pyramid point tool --- A lathe tool that is a cylindrical steel rod with the point ground down to a 3-faceted pyramid shape; used for turning beads and other spindle turning

radius skew chisel --- A lathe tool; a variation on the skew chisel in which the cutting edge is curved, allowing more flexibility in some types of cuts. Examples:

reverse chucking --- Mounting a face turning backwards so that the other side can be turned. This is most commonly applied to turning bowls, where the inside of the bowl and the upper outside is all turned and then the bowl is reversed into any of various kinds of chucks so that the outside bottom can be turned.

ring center --- Synonymous with cup center

ring tool --- A lathe tool; a steel cylinder (ring) with a cutting edge all the way around one end, sharpened with a grind on the inside of the cylinder, and usually mounted via a rod that is brazed or welded to one side of the cylinder so that the inside of the cylinder is totally free for chips to move through as the tool is used to remove material from a lathe turning. The "ring tool" is not at all the same beast as the captive ring tool. Examples:

roughing gouge --- A lathe tool used in spindle turning for quickly reducing square stock to a round section. It has a semicircular cross section and is ground square across the cutting end. The bevel angle should be around 35° to 45°. A roughing gouge is for spindle work and should not be used for face turning, as the upper edges, which are not swept back like those on a bowl gouge will tend to catch on face turnings. Examples:

roughing out gouge --- synonymous with roughing gouge

rough turning --- The lathe process of turning a square cross section turning stick into a round (dowel-like) shape, or turning a rectangular bowl blank into a roughly bowl-shaped object.

round nose scraper --- A lathe scraper that has a rectangular cross section and a rounded nose used for scraping the work. This tool may be held flat on the tool rest, or sometimes angled to produce more of a shearing action than a scraping action, but you have to be careful when doing that because the sharp edge of the tool will dig into the tool rest, possibly causing the need for more frequent dressing of that surface. The scraping edge of this tool may have the type of grind that is similar to that in the flat nosed scraper in that there is a constant angle to the flat top of the tool, or it may have what is more of a fingernail grind. Most of the examples in the composit pic below are the flat grind but the one directly above the fingernail grind illustration in the lower left corner has the fingernail grind. I use both and find both to be very effective, but the fingernail grind tools are better suited when you want a shearing action instead of scraping because they present a sharper edge to the wood. Compare/contrast to flat nosed scraper. Examples:

round nose side cutting scraper --- see side cutting scraper

round skew chisel --- An extreme extension of the much more common oval skew chisel, this variety is only made by a couple of manufacturers. Like the oval skew chisel, the point of the curved edge on the tool is to facilitate rotating the tool against tool rest for variable slicing angles as it is moved over a variable workpiece surface. Example:

scraper --- There are four types of scrapers used in woodworking. The first is the cabinet scraper which is used to produce a fine surface finish on flat or lightly curved surfaces, and second is the lathe scraper which is used to produce a fine finish on curved items in a lathe. These two are each frequently called, within their own context, just a "scraper" but in this glossary I have given them their full names and each has its own term with a full discussion, so as to clearly distinguish them from the other scrapers. Wood turners do not refer to a "lathe scraper", they just say "scraper" (or possible "round-nosed scraper" or one of the other sub-types) and likewise, when people are talking about creating a finish on a flat wood surface in cabinetry, they do not talk about a "cabinet scraper", they just say "scraper", so the distinction in this glossary using the "full" names is purely for clarity and does not reflect actual usage. There are several different types of lathe scraper, so the URL above just points to "lathe tools" which lists the various lathe scrapers. The next two are the paint scraper and the razor blade scraper. The first of these is used to remove paint from wood and metal and the second is used to remove paint (and sometimes other things) from glass. Each of the four is illustrated with its term.

scraping --- (1) Scraping cuts on a wood lathe are specific cuts where the bevel of the lathe tool is held clear of the wood and the cutting edge scrapes the surface of the wood. Scrapers have to be kept very sharp to avoid crushing the wood instead of scraping it cleanly. The term is also sometimes used to describe the incorrect use of a tool that should be doing a shearing cut but which, due to improper presentation of the edge to the workpiece, is instead doing a scraping cut.

scraping --- (2) Wood surface scraping done with a cabinet scraper to remove very thin layers of a flat or lightly curved surface.

screw chuck --- A chuck with a single screw, fixed in the center, to which the workpiece is attached on a wood lathe. Examples:

scroll chuck --- A chuck for a wood lathe (well, OK, metal lathes use them too). They may have 3 or 4 jaws (or even more), and the jaws come in various forms, the most common being a kind of staircase piece of metal and the other being circular arcs (see four jaw chuck for pics). What all scroll chucks have in common is that the operational mechanism is based on a scroll plate which is a spiral-grooved plate that acts as a gear for the underside of the jaws (see scroll plate for pics). The good news about scroll chucks is that they are a form of self centering jaw chucks and are thus easy to use. The bad news is that like all self centering jaw chucks, they are somewhat sloppy in alignment compared to independent jaw chucks, and cannot be fine tuned for centering. The jaws either compress inward on the outside of a cylindrical projection at the back of the blank, or to expand outward to grip the inside of a hollow cylindrical projection at the back of the blank. Some versions have flat edges, some have dovetailed edges for extra holding power. It is immediately apparent when looking at chuck whether it is a scroll chuck or an independent jaw chuck, because a scroll chuck only has one adjustment hole whereas on an independent jaw chuck, every jaw has an adjustment hole. Examples:

scroll plate --- The spiral grooved plate that is the heart of a scroll chuck. Examples:

segmented bowl --- A turned wooden bowl that is not made from a single piece of wood, but rather from a number of pieces glued together in some design. Segmented bowls come in a staggering variety of styles and the examples shown below hardly even touch the surface of showing some of the variety available. If there are gaps among the glued up pieces, it is called an open segmented bowl. The upper middle two are mine. Compare/contrast to other lathe turnings. Examples:

self centering chuck --- Synonymous with scroll chuck; the term emphasizes the fact that scroll chuck jaws automatically move synchronously and maintain their centering, unlike the jaws on an independent jaw chuck.

shallow detail gouge --- A detail gouge that has an extra shallow cannel. See also lathe gouge shape comparison. Examples:

shallow fluted gouge --- synonymous with spindle gouge; compare/contrast with "deep fluted gouge" which is synonymous with bowl gouge. That is, bowl gouges have a relatively deep flute and spindle gouges have a relatively shallow flute, thus the alternate names.

side cutting scraper --- A lathe tool; This term refers to a few differently shaped lathe scrapers that all have the purpose of scraping the inside surface of bowls and other containers in face turning and are rarely used in spindle turning. They are sometimes quite similar to hollowing tools. Some have a straight edge scraping surface and are called "diamond side cutting scrapers" and some have a curved scraping surface and are called "round nose side cutting scrapers" and some have a rounded section that merges into a flat section. Some have a bit of a hook, much like a hollowing tool, but I have not encountered the term "hook nose side cutting scraper". I've seen one side cutting scraper that has a long straight scraping edge and is called a "box scraper" but having found only one vendor for this tool, I have not included it in this glossary as a term. Unlike bowl scrapers, side cutting scrapers do not come in inboard and outboard versions, although I personally have had occasion to wish that they did. Examples:

skewchigouge --- A lathe tool reportedly designed by English turner Allan Beecham; works as a both a skew chisel and a gouge, thus the name skewchigouge. Sold by several manufacturers, it reportedly does not catch easily and can be used to turn beads, coves and most any other shape that can be turned with a skew chisel and/or a lathe gouge. Examples:

skew chisel --- A lathe tool; a chisel on which the cutting edge is not square to the sides of the tool but rather is at an angle (most commonly 30 degrees) off of square. The cross section taken perpendicular to the long dimension is normally a rectangle, but if it is an oval, then the chisel is called an oval skew chisel and there is one extreme case of this where the shank is a cylinder and the tool is called a round skew chisel. Skew chisels exist as both carving chisels and lathe chisels. When used with a wood lathe, they are present to the spindle with the cutting edge perpendicular to the axis of the spindle, thus removing material via slicing, not scraping. Skew chisels can also be used in exactly the same way as a square nose chisel but with the added advantage that they can get into slightly recessed areas whereas the square nose chisel cannot. I use them this way regularly when doing the versions of my bowls where the bowl surface extends under the side and a square nose scraper just can't do the job. One of the problems sometimes encountered with the skew chisel is that the rectangular cross section presents a sharp edge to the tool rest when using the tool at an angle (the normal mode of operation) and this easily catches on the tool rest. Consequently, some vendors produce skew chisels with slightly rounded edges, like the one in the upper right corner of the composite pic below, and of course the oval skew chisel totally avoids the problem. Examples:

socket --- A tapered cylinder at the end of a tool such as a file or chisel, by which the handle is attached. Compare/contrast to tang. Examples:

spear point chisel --- A lathe tool that is used to cut sharp corners or "V" shaped grooves. It has a spear shaped pointed cutting (scraping actually) edge that is usually ground to slightly less than 90 degrees since at a full 90 degrees it would be very unforgiving in scraping out right angles whereas with a little less, it can be used to work on one edge and then the other without danger of damaging the surface not being concentrated on. This tool is also called a "square end scraper" (not to be confused with a square nose scraper, a "diamond point chisel", and a "diamond point scraper", depending on the manufacturer. Examples:

spigot --- A rectangular or cylindrical projection on the end of a workpiece, made to fit into a recess such as a socket in a chair seat or in a spigot chuck.

spigot chuck --- (1) A chuck with a deep recess into which a spigot on the workpiece can be driven. In this use, the term is synonymous with "jam chuck".

spigot chuck --- (2) synonymous with cup chuck although I think it would be incorrect to call a shallow cup chuck a spigot chuck.